Ultrasonic Thickness Measurement provides precise, non-destructive evaluation of material thickness in marine engineering, enabling early detection of corrosion or erosion without requiring access to both sides of the structure. Radiographic Testing offers detailed internal imaging to detect weld defects or structural discontinuities but involves radiation exposure and requires significant safety precautions. Combining these methods enhances the accuracy and reliability of ship hull inspections and maintenance planning.

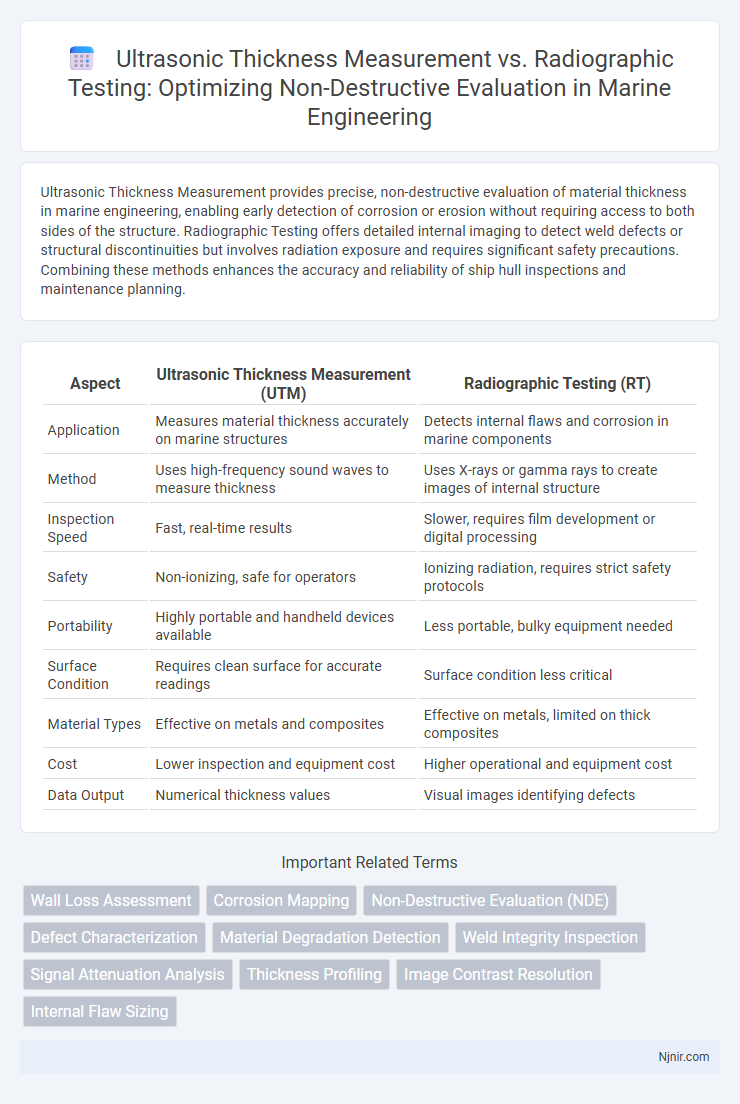

Table of Comparison

| Aspect | Ultrasonic Thickness Measurement (UTM) | Radiographic Testing (RT) |

|---|---|---|

| Application | Measures material thickness accurately on marine structures | Detects internal flaws and corrosion in marine components |

| Method | Uses high-frequency sound waves to measure thickness | Uses X-rays or gamma rays to create images of internal structure |

| Inspection Speed | Fast, real-time results | Slower, requires film development or digital processing |

| Safety | Non-ionizing, safe for operators | Ionizing radiation, requires strict safety protocols |

| Portability | Highly portable and handheld devices available | Less portable, bulky equipment needed |

| Surface Condition | Requires clean surface for accurate readings | Surface condition less critical |

| Material Types | Effective on metals and composites | Effective on metals, limited on thick composites |

| Cost | Lower inspection and equipment cost | Higher operational and equipment cost |

| Data Output | Numerical thickness values | Visual images identifying defects |

Introduction to Non-Destructive Testing in Marine Engineering

Ultrasonic Thickness Measurement (UTM) and Radiographic Testing (RT) are essential non-destructive testing (NDT) techniques used in marine engineering to ensure structural integrity and safety. UTM employs high-frequency sound waves to accurately measure material thickness and detect internal corrosion without damaging the component, making it ideal for inspecting ship hulls and offshore structures. Radiographic Testing uses X-rays or gamma rays to produce images of a material's internal features, revealing weld defects and cracks, and is critical for quality control in marine fabrication and maintenance.

Principles of Ultrasonic Thickness Measurement

Ultrasonic Thickness Measurement utilizes high-frequency sound waves that are transmitted into a material, where the time taken for the echo to return from the opposite surface determines the thickness. This non-destructive testing method relies on the principle of acoustic pulse-echo, providing precise thickness measurements even through coatings or corrosion. The technology is widely used in industries such as aerospace, petrochemical, and manufacturing for inspecting metal, plastic, and composite materials without requiring direct access to the material's back surface.

Fundamentals of Radiographic Testing

Radiographic Testing (RT) uses X-rays or gamma rays to penetrate materials and create images that reveal internal flaws or thickness variations. The process relies on the differential absorption of radiation by different material densities, producing a contrast on the radiographic film or digital detector. RT is highly effective for detecting volumetric defects such as cracks, voids, and inclusions, providing a permanent record of the inspection.

Application Areas in Marine Structures

Ultrasonic thickness measurement is extensively applied in marine structures for corrosion monitoring, hull thickness evaluation, and maintenance inspections due to its ability to provide precise, real-time thickness readings without requiring access to both sides of a material. Radiographic testing is primarily used for detecting internal flaws and weld quality assessment in shipbuilding and offshore platforms, offering detailed imagery of structural integrity. Both methods complement each other in marine applications, where ultrasonic techniques excel in corrosion mapping, while radiography is preferred for comprehensive weld inspection and defect characterization.

Accuracy and Resolution Comparison

Ultrasonic Thickness Measurement offers superior accuracy with precision often reaching +-0.01 mm, enabling detailed wall thickness readings critical for corrosion monitoring. Radiographic Testing, while effective for detecting internal flaws, provides lower resolution images that may obscure fine defects and yield less precise thickness data. The high-frequency ultrasonic waves deliver clearer, more quantifiable measurements compared to radiographic film grain and exposure variables that impact image resolution.

Safety Considerations and Risks

Ultrasonic thickness measurement offers a non-invasive, radiation-free method for assessing material integrity, significantly reducing health risks associated with exposure to ionizing radiation in radiographic testing. Radiographic testing involves the use of X-rays or gamma rays, requiring strict safety protocols to protect operators from potential radiation hazards, including long-term cancer risks. Proper training, shielding, and monitoring are essential in radiographic testing, whereas ultrasonic testing emphasizes safe handling of equipment and accurate calibration to prevent measurement errors.

Inspection Speed and Operational Efficiency

Ultrasonic thickness measurement offers faster inspection speed compared to radiographic testing due to its ability to provide immediate digital thickness readings without the need for film development or extensive setup. Operational efficiency is enhanced by ultrasonic methods because they require less safety precautions and can be performed on-site with portable equipment, reducing downtime and labor costs. Radiographic testing, while offering detailed imaging for flaw detection, typically involves longer process times and stricter safety protocols, impacting overall inspection throughput.

Detectable Defect Types and Limitations

Ultrasonic Thickness Measurement excels in detecting internal and surface flaws such as corrosion, erosion, and thinning with high accuracy but struggles with complex geometries and requires proper surface preparation. Radiographic Testing identifies volumetric defects like voids, cracks, and inclusions by producing a permanent visual record, yet it is limited by radiation safety concerns and lower sensitivity to planar defects. Both methods complement each other, with ultrasonic testing offering rapid thickness profiling and radiography providing detailed imaging of internal structures.

Cost Implications and Resource Requirements

Ultrasonic thickness measurement typically offers lower cost implications due to minimal equipment expenses and rapid inspection times, reducing labor costs significantly. Radiographic testing demands higher resource investments, including expensive imaging materials, protective environments, and specialized personnel, leading to increased operational costs. The choice between methods hinges on budget constraints, required inspection depth, and availability of trained technicians, with ultrasonic technology favored for cost-effective, routine assessments.

Choosing the Optimal Method for Marine Engineers

Ultrasonic Thickness Measurement offers precise, non-destructive evaluation of material thickness, making it ideal for real-time corrosion monitoring and maintenance in marine environments. Radiographic Testing provides detailed internal imaging to detect weld defects and structural flaws, essential for comprehensive inspection during shipbuilding and major repairs. Marine engineers prioritize ultrasonic techniques for routine inspections due to speed and safety, while radiography is preferred for critical assessments requiring in-depth analysis of complex geometries.

Wall Loss Assessment

Ultrasonic Thickness Measurement provides precise quantification of wall loss by directly measuring material thickness, while Radiographic Testing offers visual imaging to detect wall loss but lacks the exact thickness measurement accuracy.

Corrosion Mapping

Ultrasonic thickness measurement provides precise corrosion mapping by detecting metal loss at multiple points with high accuracy, whereas radiographic testing offers a visual representation of corrosion but lacks the same resolution and quantitative thickness data.

Non-Destructive Evaluation (NDE)

Ultrasonic Thickness Measurement offers precise, real-time thickness data for Non-Destructive Evaluation (NDE) with minimal safety risks and portability advantages, while Radiographic Testing provides detailed internal imaging essential for detecting volumetric flaws but involves radiation exposure and higher operational costs.

Defect Characterization

Ultrasonic thickness measurement provides precise, real-time defect depth and size characterization in materials, while radiographic testing excels in detecting internal volumetric flaws but offers limited quantitative defect dimension data.

Material Degradation Detection

Ultrasonic thickness measurement offers precise quantification of material degradation by detecting wall thinning, while radiographic testing provides detailed imaging to identify internal flaws and corrosion within materials.

Weld Integrity Inspection

Ultrasonic Thickness Measurement provides precise metal thickness data for weld integrity evaluation, while Radiographic Testing reveals internal weld defects through X-ray imaging, together enhancing comprehensive weld quality inspection.

Signal Attenuation Analysis

Ultrasonic Thickness Measurement provides precise signal attenuation analysis for material degradation assessment, while Radiographic Testing relies on image density variations without direct attenuation quantification.

Thickness Profiling

Ultrasonic Thickness Measurement provides precise, real-time thickness profiling of materials by using high-frequency sound waves, whereas Radiographic Testing offers less detailed thickness data by capturing 2D X-ray images primarily for detecting internal defects.

Image Contrast Resolution

Ultrasonic thickness measurement provides superior image contrast resolution for detecting material flaws compared to radiographic testing, which often suffers from lower contrast and overlapping image artifacts.

Internal Flaw Sizing

Ultrasonic Thickness Measurement provides precise internal flaw sizing by measuring material thickness and detecting subsurface defects, whereas Radiographic Testing offers detailed imaging of internal flaws but with less accuracy in quantifying flaw size.

Ultrasonic Thickness Measurement vs Radiographic Testing Infographic

njnir.com

njnir.com