Hull fouling significantly increases drag and reduces vessel speed, leading to higher fuel consumption and maintenance costs in marine engineering. Propeller fouling, on the other hand, directly impacts propulsion efficiency, causing vibrations and power loss that negatively affect maneuverability. Effective antifouling coatings and regular cleaning are essential to maintain optimal performance and extend the lifespan of both hull and propeller components.

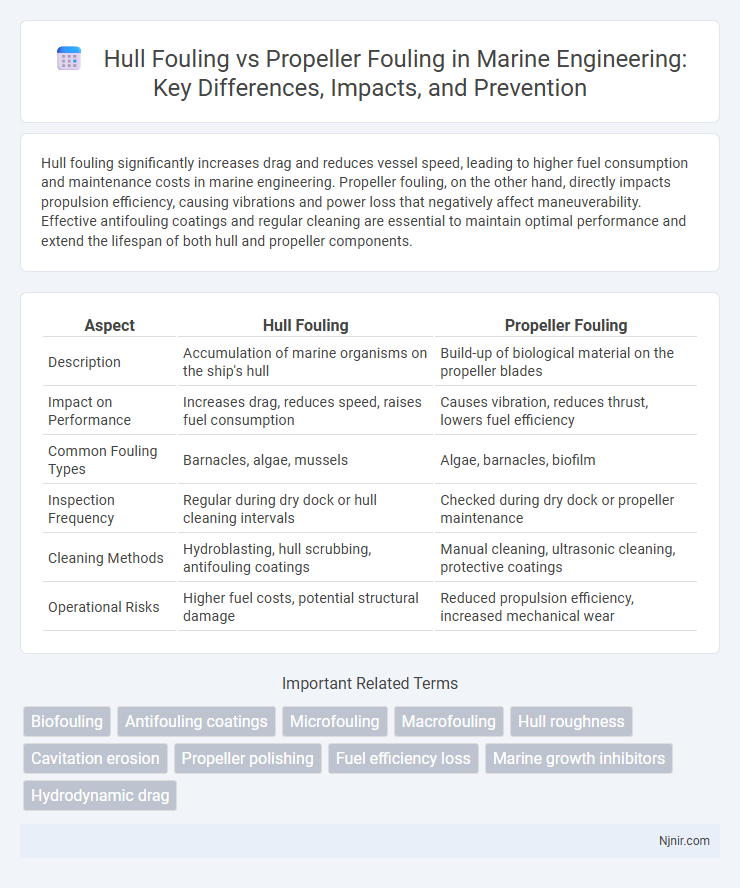

Table of Comparison

| Aspect | Hull Fouling | Propeller Fouling |

|---|---|---|

| Description | Accumulation of marine organisms on the ship's hull | Build-up of biological material on the propeller blades |

| Impact on Performance | Increases drag, reduces speed, raises fuel consumption | Causes vibration, reduces thrust, lowers fuel efficiency |

| Common Fouling Types | Barnacles, algae, mussels | Algae, barnacles, biofilm |

| Inspection Frequency | Regular during dry dock or hull cleaning intervals | Checked during dry dock or propeller maintenance |

| Cleaning Methods | Hydroblasting, hull scrubbing, antifouling coatings | Manual cleaning, ultrasonic cleaning, protective coatings |

| Operational Risks | Higher fuel costs, potential structural damage | Reduced propulsion efficiency, increased mechanical wear |

Understanding Hull and Propeller Fouling

Hull fouling primarily involves the accumulation of marine organisms such as algae, barnacles, and mussels on the ship's hull, increasing drag and reducing fuel efficiency. Propeller fouling, however, specifically targets the propeller blades, causing vibration, decreased thrust, and higher fuel consumption due to disrupted water flow. Understanding the differences in fouling types is essential for optimizing maintenance schedules and enhancing vessel performance.

Causes of Hull Fouling in Marine Vessels

Hull fouling in marine vessels primarily occurs due to the accumulation of microorganisms, algae, barnacles, and other marine life attaching to the submerged surfaces of the ship's hull. This biological growth is triggered by factors such as water temperature, salinity, nutrient availability, and the hull's material composition or coating. Unlike propeller fouling, which mainly results from debris and marine growth on the rotating blades, hull fouling is influenced by prolonged exposure to contaminated waters and poor maintenance practices.

Mechanisms Behind Propeller Fouling

Propeller fouling primarily occurs due to the accumulation of marine organisms, such as barnacles, algae, and bacterial biofilms, on the propeller surface, which disrupts hydrodynamic efficiency and increases fuel consumption. Unlike hull fouling, which is often mitigated by antifouling coatings, propeller fouling is influenced by the interaction between water flow dynamics and surface roughness, promoting biofilm adhesion and colonization. The mechanical action of the propeller and its material composition also impact the extent and type of fouling, with slower rotational speeds and less corrosion-resistant materials being more susceptible.

Comparative Impacts on Vessel Performance

Hull fouling and propeller fouling both significantly degrade vessel performance by increasing drag and reducing fuel efficiency, but propeller fouling typically causes more severe power loss and vibration issues. Hull fouling, involving barnacles and algae buildup on the hull, primarily increases hydrodynamic resistance, leading to slower speeds and higher fuel consumption. In contrast, propeller fouling, such as marine growth or debris accumulation on blades, directly disrupts propulsion efficiency, causing up to a 20% increase in fuel usage and greater engine strain.

Fuel Efficiency: Hull Fouling vs Propeller Fouling

Hull fouling increases drag on the vessel's surface, causing the engine to work harder and significantly reducing fuel efficiency by up to 40%. Propeller fouling creates uneven surfaces and increased resistance, decreasing propulsion efficiency and potentially raising fuel consumption by approximately 15-25%. Efficient maintenance of both hull and propeller fouling is essential to optimize fuel use and reduce operational costs.

Detection and Monitoring Methods

Hull fouling detection primarily relies on visual inspections, underwater drones equipped with high-resolution cameras, and sonar imaging to identify biofilm accumulation and marine growth on the vessel's hull. Propeller fouling is monitored using vibration analysis sensors and performance metrics such as increased fuel consumption or reduced thrust efficiency, complemented by underwater ROV inspections to detect barnacle or algae build-up. Advanced technologies like ultrasonic antifouling sensors and AI-driven image processing systems enhance early detection accuracy and facilitate continuous monitoring for both hull and propeller fouling.

Prevention and Treatment Techniques

Hull fouling prevention involves regular hull cleaning, applying anti-fouling paints, and using ultrasonic antifouling systems to inhibit marine organism attachment. Propeller fouling is minimized through frequent inspections, propeller polishing, and coating with specialized anti-fouling materials designed to reduce drag and maintain efficiency. Treatment techniques for both include mechanical cleaning, chemical biocides, and advanced technologies like laser cleaning to restore optimal performance and reduce fuel consumption.

Economic Costs: Hull vs Propeller Maintenance

Hull fouling increases fuel consumption by up to 40%, leading to significant operational cost surges due to higher fuel expenses and extended voyage times. Propeller fouling decreases propulsion efficiency by approximately 15-20%, causing increased engine load and maintenance frequency that escalate repair costs. Maintenance of hull fouling typically demands dry-docking and specialized cleaning, often costing $50,000 to $200,000 per event, while propeller fouling treatments are less expensive but require more frequent intervention to maintain optimal vessel performance.

Environmental Implications of Marine Fouling

Hull fouling increases drag and fuel consumption, leading to higher greenhouse gas emissions and greater environmental pollution. Propeller fouling reduces propulsion efficiency, causing vessels to burn more fuel and emit more CO2. Both types of fouling contribute to invasive species transfer, disrupting marine ecosystems and biodiversity.

Regulatory and Compliance Considerations

Hull fouling and propeller fouling both significantly impact vessel efficiency and are subject to maritime regulatory frameworks such as the International Maritime Organization's (IMO) guidelines on biofouling management to prevent invasive species transfer. Regulations often mandate regular inspections and maintenance schedules for hull cleaning and propeller polishing to comply with environmental protection standards, including MARPOL Annex V. Failure to meet these compliance requirements can result in penalties, operational restrictions, and increased fuel consumption due to increased drag and decreased propulsion efficiency.

Biofouling

Biofouling on hulls significantly increases drag and fuel consumption, while propeller fouling primarily reduces propulsion efficiency and maneuverability.

Antifouling coatings

Antifouling coatings effectively reduce hull fouling by preventing marine organism accumulation on ship hulls, while specialized propeller coatings target propeller fouling to maintain optimal thrust and fuel efficiency.

Microfouling

Microfouling accelerates hull fouling by promoting biofilm formation on submerged surfaces and increases propeller fouling by reducing hydrodynamic efficiency and causing vibration.

Macrofouling

Macrofouling on ship hulls significantly increases drag and fuel consumption, while propeller fouling primarily reduces propulsion efficiency and can cause vibration and damage.

Hull roughness

Hull roughness from fouling significantly increases hydrodynamic drag compared to propeller fouling, leading to higher fuel consumption and reduced vessel speed.

Cavitation erosion

Hull fouling increases drag and fuel consumption while propeller fouling, particularly with cavitation erosion, causes blade surface damage, reducing propulsion efficiency and vessel performance.

Propeller polishing

Propeller polishing significantly reduces propeller fouling by smoothing surfaces to prevent marine organism accumulation, enhancing vessel efficiency and fuel economy compared to hull fouling management.

Fuel efficiency loss

Hull fouling increases fuel consumption by up to 20%, while propeller fouling can reduce fuel efficiency by as much as 25% due to increased drag and disrupted water flow.

Marine growth inhibitors

Marine growth inhibitors effectively prevent hull fouling by reducing organism attachment on vessel surfaces, whereas propeller fouling requires specialized inhibitors to maintain propulsion efficiency and prevent corrosion.

Hydrodynamic drag

Hull fouling increases hydrodynamic drag by roughening the ship's surface, while propeller fouling reduces propulsion efficiency by disrupting water flow and causing cavitation.

hull fouling vs propeller fouling Infographic

njnir.com

njnir.com