Condition-based monitoring in marine engineering utilizes real-time data and sensor analytics to predict equipment failures, enhancing operational efficiency and reducing unplanned downtime. Time-based maintenance relies on predetermined schedules regardless of equipment condition, often leading to unnecessary repairs or unexpected breakdowns. Implementing condition-based monitoring improves resource allocation and extends the lifespan of critical marine components by addressing issues only when sensor data indicates a decline in performance.

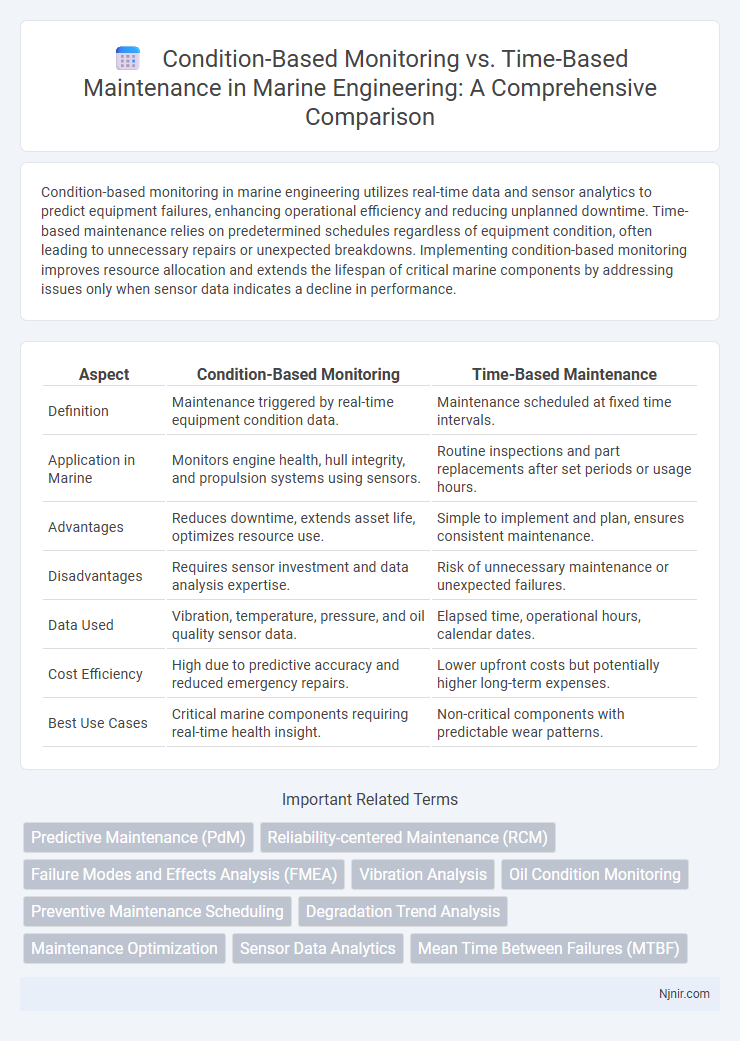

Table of Comparison

| Aspect | Condition-Based Monitoring | Time-Based Maintenance |

|---|---|---|

| Definition | Maintenance triggered by real-time equipment condition data. | Maintenance scheduled at fixed time intervals. |

| Application in Marine | Monitors engine health, hull integrity, and propulsion systems using sensors. | Routine inspections and part replacements after set periods or usage hours. |

| Advantages | Reduces downtime, extends asset life, optimizes resource use. | Simple to implement and plan, ensures consistent maintenance. |

| Disadvantages | Requires sensor investment and data analysis expertise. | Risk of unnecessary maintenance or unexpected failures. |

| Data Used | Vibration, temperature, pressure, and oil quality sensor data. | Elapsed time, operational hours, calendar dates. |

| Cost Efficiency | High due to predictive accuracy and reduced emergency repairs. | Lower upfront costs but potentially higher long-term expenses. |

| Best Use Cases | Critical marine components requiring real-time health insight. | Non-critical components with predictable wear patterns. |

Understanding Condition-Based Monitoring in Marine Engineering

Condition-based monitoring in marine engineering utilizes real-time data from sensors measuring vibration, temperature, and pressure to predict equipment failures before they occur, enhancing reliability and reducing downtime. Unlike time-based maintenance, which relies on fixed schedules regardless of actual equipment condition, condition-based monitoring enables targeted interventions that optimize resource use and extend asset lifespan. Implementing advanced diagnostic tools such as ultrasonic testing and oil analysis accelerates fault detection, ensuring safer and more cost-effective vessel operations.

Fundamentals of Time-Based Maintenance for Marine Equipment

Time-based maintenance for marine equipment involves scheduled inspections and part replacements at fixed intervals, regardless of actual equipment condition, ensuring consistent operational reliability. This fundamental approach relies on manufacturer recommendations and historical data to prevent unexpected failures by addressing wear and tear before it leads to breakdowns. While effective in managing predictable maintenance tasks, time-based maintenance may result in unnecessary servicing or missed early signs of equipment degradation compared to condition-based monitoring.

Key Differences: Condition-Based vs Time-Based Maintenance

Condition-based monitoring relies on real-time data and sensor inputs to assess equipment health, triggering maintenance only when specific performance thresholds are met. Time-based maintenance follows a fixed schedule, performing inspections and replacements at predetermined intervals regardless of the asset's actual condition. The key difference lies in efficiency and cost-effectiveness, with condition-based approaches reducing unnecessary maintenance and preventing unexpected failures, while time-based methods offer simplicity but may lead to over-maintenance or missed early warning signs.

Advantages of Condition-Based Monitoring in Marine Applications

Condition-based monitoring (CBM) in marine applications offers precise real-time data on equipment health, enabling targeted maintenance that reduces unplanned downtime and extends the lifespan of critical machinery such as engines, pumps, and turbines. CBM enhances safety by early detection of potential failures through advanced sensor technology and predictive analytics, minimizing the risk of catastrophic marine incidents. This approach also lowers maintenance costs and improves operational efficiency by replacing routine time-based maintenance with maintenance performed only when necessary, optimizing resource allocation on vessels.

Limitations of Time-Based Maintenance in Marine Engineering

Time-based maintenance in marine engineering often results in unnecessary part replacements and increased downtime due to its fixed schedule approach that does not consider actual equipment condition. This method overlooks the variability in operating conditions and wear rates, leading to inefficiencies and higher maintenance costs. The inability to predict failures precisely can cause unexpected breakdowns, compromising safety and operational reliability on marine vessels.

Impact on Vessel Reliability and Operational Efficiency

Condition-based monitoring enhances vessel reliability by using real-time sensor data to predict maintenance needs, minimizing unexpected breakdowns and costly downtime. Time-based maintenance relies on predetermined schedules that may lead to unnecessary part replacements or missed failures, reducing operational efficiency. Implementing condition-based strategies optimizes resource allocation and extends equipment lifespan, significantly improving overall vessel performance.

Cost Implications: Condition-Based vs Time-Based Strategies

Condition-based monitoring reduces maintenance costs by targeting repairs only when data indicates potential equipment failure, minimizing unnecessary part replacements and labor. Time-based maintenance often incurs higher expenses due to scheduled interventions regardless of actual equipment condition, leading to premature servicing and resource wastage. Implementing condition-based strategies can improve budget allocation by focusing efforts on machines exhibiting wear signs, enhancing overall operational cost efficiency.

Role of Technology in Modern Marine Maintenance Approaches

Condition-based monitoring leverages advanced sensor technologies and real-time data analytics to assess equipment health, enabling predictive maintenance and reducing unplanned downtime in marine systems. Time-based maintenance relies on scheduled inspections and component replacements, which may lead to unnecessary servicing or unexpected failures due to static intervals. Modern marine maintenance increasingly integrates IoT devices, machine learning algorithms, and digital twins to optimize condition-based strategies, enhancing operational efficiency and extending asset lifespan.

Case Studies: Real-World Applications in the Maritime Industry

Case studies in the maritime industry demonstrate that condition-based monitoring (CBM) significantly improves equipment reliability by utilizing real-time sensory data to predict failures before they occur, contrasting with traditional time-based maintenance (TBM) schedules which often lead to unnecessary part replacements or unexpected breakdowns. Vessels implementing CBM report reduced downtime and maintenance costs by focusing on critical components such as engines and propulsion systems, leveraging technologies like vibration analysis, oil condition monitoring, and thermal imaging. These real-world applications underline how CBM's data-driven maintenance enhances operational efficiency and safety compared to fixed-interval TBM strategies.

Future Trends in Marine Maintenance Strategies

Future trends in marine maintenance strategies emphasize the shift from traditional time-based maintenance (TBM) to condition-based monitoring (CBM) enabled by advanced sensors and IoT technologies. CBM uses real-time data analytics and predictive algorithms to optimize maintenance schedules, reducing downtime and operational costs while enhancing equipment reliability. Integration of AI and machine learning will further refine fault detection and prognostics, driving smarter, automated maintenance decision-making in marine vessels.

Predictive Maintenance (PdM)

Predictive Maintenance (PdM) leverages Condition-Based Monitoring by analyzing real-time data and machine health indicators to optimize maintenance schedules, reducing downtime and costs compared to traditional Time-Based Maintenance that relies on fixed intervals.

Reliability-centered Maintenance (RCM)

Reliability-centered Maintenance (RCM) prioritizes condition-based monitoring over time-based maintenance by using real-time data and asset health indicators to optimize maintenance scheduling and enhance equipment reliability.

Failure Modes and Effects Analysis (FMEA)

Condition-based monitoring enhances Failure Modes and Effects Analysis (FMEA) by providing real-time data to predict failure modes more accurately compared to scheduled inspections in Time-based maintenance.

Vibration Analysis

Vibration analysis enhances condition-based monitoring by detecting machinery faults in real-time, improving maintenance accuracy compared to scheduled time-based maintenance.

Oil Condition Monitoring

Oil condition monitoring in condition-based monitoring enhances equipment reliability by detecting lubricant degradation, compared to the routine schedule of time-based maintenance that may overlook early signs of oil wear.

Preventive Maintenance Scheduling

Condition-based monitoring optimizes preventive maintenance scheduling by using real-time equipment data to predict failures, whereas time-based maintenance relies on fixed intervals regardless of actual asset condition.

Degradation Trend Analysis

Degradation trend analysis in condition-based monitoring enables predictive maintenance by continuously tracking asset performance metrics, whereas time-based maintenance relies on scheduled interventions without real-time degradation data.

Maintenance Optimization

Condition-based monitoring enhances maintenance optimization by using real-time data to predict equipment failures, reducing unnecessary time-based maintenance and minimizing downtime.

Sensor Data Analytics

Sensor data analytics enhances condition-based monitoring by enabling real-time equipment performance analysis and predictive maintenance, outperforming traditional time-based maintenance schedules that rely on fixed intervals.

Mean Time Between Failures (MTBF)

Condition-based monitoring extends Mean Time Between Failures (MTBF) by enabling real-time detection of equipment degradation, whereas time-based maintenance relies on fixed schedules that may either underutilize or overmaintain assets.

Condition-based monitoring vs Time-based maintenance Infographic

njnir.com

njnir.com