Engine Shut Down (ESD) in marine engineering is a critical safety feature designed to immediately halt engine operation to prevent damage during emergencies or hazardous conditions. Slow steaming reduces engine speed to improve fuel efficiency and lower emissions, balancing operational costs with environmental compliance. Prioritizing ESD ensures vessel safety, while slow steaming optimizes performance during non-critical phases.

Table of Comparison

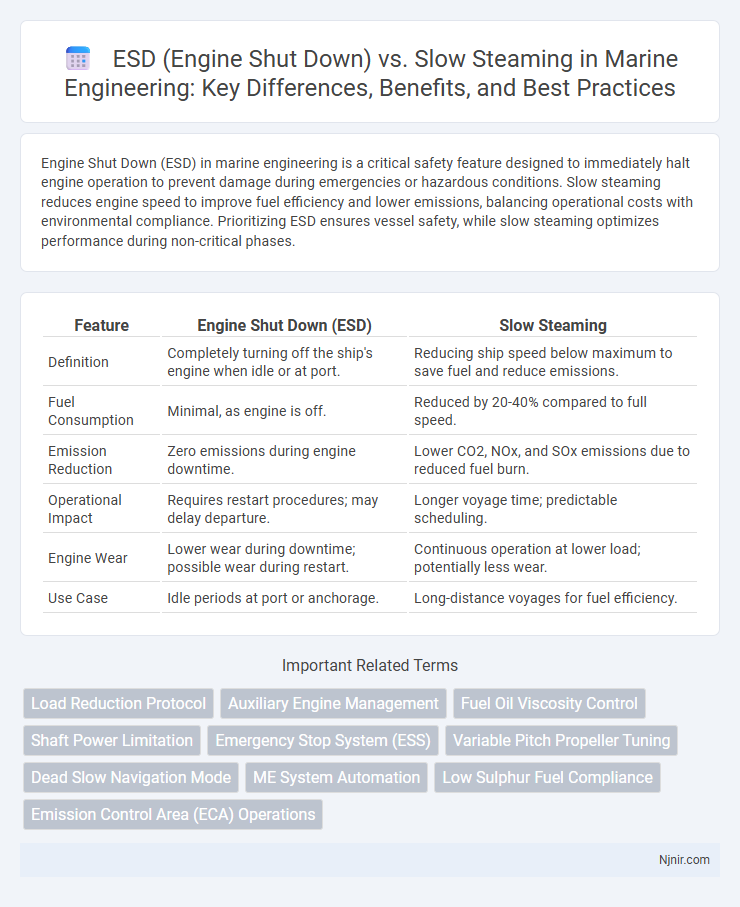

| Feature | Engine Shut Down (ESD) | Slow Steaming |

|---|---|---|

| Definition | Completely turning off the ship's engine when idle or at port. | Reducing ship speed below maximum to save fuel and reduce emissions. |

| Fuel Consumption | Minimal, as engine is off. | Reduced by 20-40% compared to full speed. |

| Emission Reduction | Zero emissions during engine downtime. | Lower CO2, NOx, and SOx emissions due to reduced fuel burn. |

| Operational Impact | Requires restart procedures; may delay departure. | Longer voyage time; predictable scheduling. |

| Engine Wear | Lower wear during downtime; possible wear during restart. | Continuous operation at lower load; potentially less wear. |

| Use Case | Idle periods at port or anchorage. | Long-distance voyages for fuel efficiency. |

Introduction to ESD and Slow Steaming in Marine Engineering

Engine Shut Down (ESD) and slow steaming are crucial strategies in marine engineering aimed at reducing fuel consumption and emissions during vessel operations. ESD involves completely shutting down the engine during idle periods, effectively minimizing unnecessary fuel use and wear, while slow steaming reduces engine speed to optimize fuel efficiency without stopping the engine. Both techniques play a significant role in enhancing environmental sustainability and operational cost-effectiveness in the shipping industry.

Defining Engine Shut Down (ESD) in Maritime Operations

Engine Shut Down (ESD) in maritime operations refers to the deliberate powering off of a vessel's main engine during transit to reduce fuel consumption and emissions. Unlike slow steaming, which reduces engine speed while maintaining operation, ESD requires alternative propulsion methods such as auxiliary engines or sails to maintain minimal maneuverability. This technique optimizes energy efficiency and environmental compliance by minimizing engine use during low-demand periods.

Understanding Slow Steaming: Concepts and Applications

Slow steaming reduces vessel speed to minimize fuel consumption and emissions, offering significant cost savings compared to standard operating speeds. Engine Shut Down (ESD) involves turning off the main engine during stops or in specific conditions, enhancing energy efficiency and lowering operational costs. Combining slow steaming with ESD strategies allows shipping companies to optimize fuel use, reduce greenhouse gas emissions, and align with environmental regulations.

Key Differences Between ESD and Slow Steaming

ESD (Engine Shut Down) involves completely turning off ship engines during idle periods to reduce fuel consumption and emissions, while slow steaming maintains reduced engine speeds to lower fuel use without stopping propulsion entirely. Key differences include that ESD minimizes operational costs and environmental impact by halting engine activity, whereas slow steaming balances fuel efficiency with schedule adherence by operating at reduced speeds. ESD can lead to potential downtime and system restart challenges, whereas slow steaming offers continuous operation with extended transit times.

Energy Efficiency Impacts: ESD vs Slow Steaming

Engine Shutdown (ESD) significantly reduces fuel consumption and greenhouse gas emissions by completely halting engine operations during idle periods, leading to substantial energy efficiency gains. Slow steaming, while reducing engine power and fuel use by decreasing vessel speed, results in longer transit times, which can offset some environmental benefits. Comparative studies show ESD offers greater overall energy savings, especially in port or anchorage scenarios where engines can be safely turned off without impacting schedules.

Safety Considerations in ESD and Slow Steaming Procedures

Engine Shut Down (ESD) and slow steaming procedures require strict adherence to safety protocols to prevent mechanical failures and ensure crew safety. ESD demands careful monitoring of engine parameters and proper cooling to avoid damage from thermal stress, while slow steaming necessitates continuous vigilance to maintain engine stability and respond promptly to any abnormal vibrations or temperature fluctuations. Both procedures involve comprehensive crew training and real-time communication to mitigate risks associated with reduced engine activity.

Environmental Implications of Engine Shut Down and Slow Steaming

Engine Shut Down (ESD) significantly reduces fuel consumption and greenhouse gas emissions by turning off engines when vessels are idle, directly lowering carbon dioxide and nitrogen oxide output. Slow steaming decreases engine load by reducing vessel speed, which enhances fuel efficiency and cuts sulfur oxide and particulate matter emissions, contributing to lower overall air pollution. Both strategies complement maritime decarbonization efforts and help meet International Maritime Organization (IMO) emissions reduction targets for shipping.

Operational Challenges: ESD Compared to Slow Steaming

Engine Shut Down (ESD) presents operational challenges such as the need for precise timing and coordination to avoid delays and maintain schedule integrity, whereas slow steaming involves adjusting vessel speed consistently, requiring less complex maneuvering but increasing voyage duration. ESD risks include potential engine wear and restart issues, demanding stringent maintenance protocols, while slow steaming impacts fuel efficiency and may limit cargo throughput due to prolonged transit times. Both methods necessitate careful planning to balance fuel savings with operational reliability and service commitments.

Best Practices for Implementing ESD and Slow Steaming

Best practices for implementing Engine Shut Down (ESD) and slow steaming include precise voyage planning to optimize fuel savings while minimizing schedule delays and emissions. Continuous monitoring of engine performance and real-time weather data ensures optimal speed adjustments and timely engine shut down, maintaining vessel safety and operational efficiency. Integrating digital tools for predictive analytics supports decision-making by balancing operational costs with environmental compliance goals.

Future Trends in Marine Propulsion: ESD and Slow Steaming

Future trends in marine propulsion emphasize energy efficiency and emission reduction, with Engine Shut Down (ESD) and slow steaming as key strategies. ESD technology enables vessels to power down main engines during idle or low-demand periods, significantly reducing fuel consumption and greenhouse gas emissions. Slow steaming complements this by optimizing vessel speed to lower fuel usage without compromising schedules, collectively driving the industry's transition toward greener shipping practices and compliance with IMO 2030 and 2050 emission targets.

Load Reduction Protocol

The Load Reduction Protocol prioritizes Engine Shut Down (ESD) over slow steaming to enhance fuel efficiency and minimize emissions during periods of reduced power demand.

Auxiliary Engine Management

Effective auxiliary engine management during ESD (engine shut down) significantly reduces fuel consumption and emissions compared to slow steaming, optimizing vessel operational efficiency.

Fuel Oil Viscosity Control

Engine shut down (ESD) during slow steaming significantly improves fuel oil viscosity control by preventing fuel degradation and ensuring optimal combustion efficiency.

Shaft Power Limitation

ESD restricts shaft power by shutting the engine off to eliminate fuel consumption, while slow steaming limits shaft power output by reducing engine speed to optimize fuel efficiency without complete shutdown.

Emergency Stop System (ESS)

The Emergency Stop System (ESS) in Engine Shut Down (ESD) protocols provides immediate engine immobilization for safety, while slow steaming optimizes fuel efficiency by reducing engine speed without triggering ESS.

Variable Pitch Propeller Tuning

Variable Pitch Propeller Tuning enhances fuel efficiency by optimizing thrust during engine shut down (ESD) and slow steaming, enabling smoother power adjustments and reduced emissions.

Dead Slow Navigation Mode

Dead Slow Navigation Mode during engine shutdown (ESD) minimizes fuel consumption and emissions more effectively than slow steaming by completely stopping propulsion while maintaining essential onboard operations.

ME System Automation

ME System Automation enhances engine shut down (ESD) protocols by optimizing fuel efficiency and emissions reduction compared to slow steaming techniques in maritime operations.

Low Sulphur Fuel Compliance

Engine shut down during port stays significantly reduces emissions and ensures low sulphur fuel compliance compared to slow steaming, which maintains engine operation and may still produce higher sulphur emissions.

Emission Control Area (ECA) Operations

Engine shut down (ESD) during Emission Control Area (ECA) operations significantly reduces sulfur oxide (SOx) and nitrogen oxide (NOx) emissions compared to slow steaming, enhancing compliance with stringent ECA environmental regulations.

ESD (engine shut down) vs slow steaming Infographic

njnir.com

njnir.com