Digital twin technology revolutionizes marine engineering by providing real-time, dynamic simulations of vessels and systems that traditional modeling cannot match. Unlike static models, digital twins integrate sensor data and machine learning to predict maintenance needs and optimize performance continuously. This approach enhances decision-making accuracy, reduces downtime, and improves overall vessel efficiency in complex marine environments.

Table of Comparison

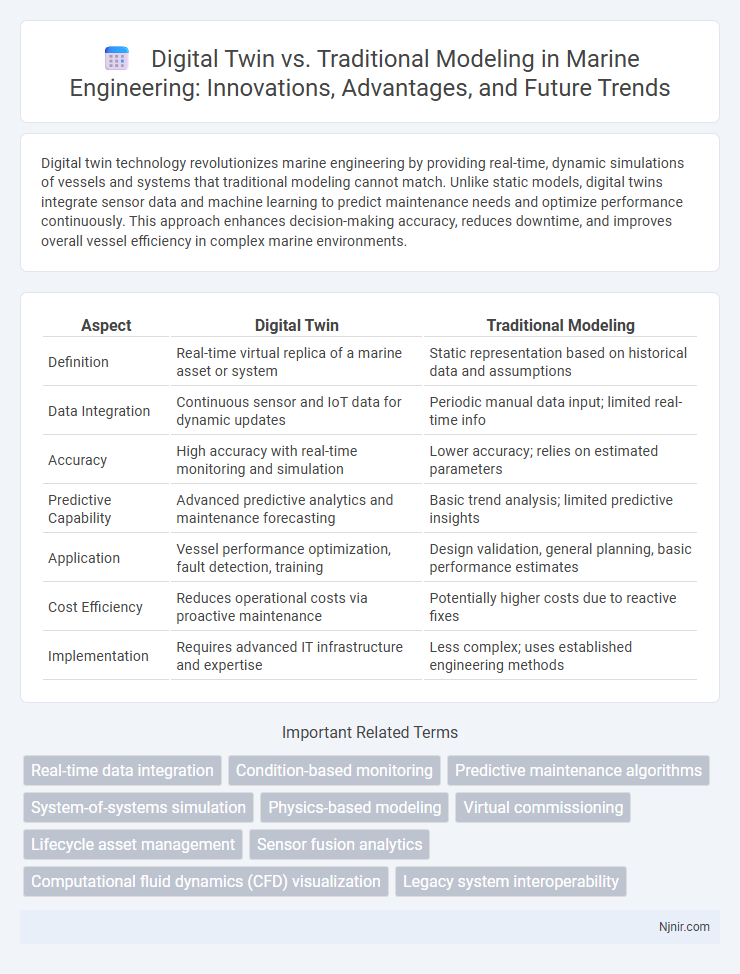

| Aspect | Digital Twin | Traditional Modeling |

|---|---|---|

| Definition | Real-time virtual replica of a marine asset or system | Static representation based on historical data and assumptions |

| Data Integration | Continuous sensor and IoT data for dynamic updates | Periodic manual data input; limited real-time info |

| Accuracy | High accuracy with real-time monitoring and simulation | Lower accuracy; relies on estimated parameters |

| Predictive Capability | Advanced predictive analytics and maintenance forecasting | Basic trend analysis; limited predictive insights |

| Application | Vessel performance optimization, fault detection, training | Design validation, general planning, basic performance estimates |

| Cost Efficiency | Reduces operational costs via proactive maintenance | Potentially higher costs due to reactive fixes |

| Implementation | Requires advanced IT infrastructure and expertise | Less complex; uses established engineering methods |

Introduction to Digital Twin and Traditional Modeling

Digital twin technology creates a dynamic, real-time virtual replica of physical systems, enabling continuous data integration and predictive analytics, unlike traditional modeling which relies on static, simplified representations based on historical data. Traditional modeling often involves predefined equations and assumptions, limiting flexibility and real-time updates, whereas digital twins leverage IoT sensors and AI to simulate complex behaviors and optimize performance continuously. The integration of real-time data streams in digital twins enhances decision-making and system maintenance beyond the capabilities of conventional predictive models.

Core Principles of Digital Twin Technology

Digital twin technology leverages real-time data integration, continuous synchronization, and advanced simulation to create dynamic, virtual replicas of physical systems, enabling proactive monitoring and predictive maintenance. Unlike traditional modeling, which relies on static or periodic data inputs and predefined assumptions, digital twins continuously update to reflect actual operational conditions, enhancing accuracy and responsiveness. Core principles include bidirectional data flow, real-time analytics, and closed-loop feedback mechanisms that optimize system performance and lifecycle management.

Foundations of Traditional Modeling in Marine Engineering

Traditional modeling in marine engineering relies on static mathematical equations and physical prototypes to simulate vessel behavior under specific conditions. These models often use simplified assumptions and fixed parameters, limiting their adaptability to real-time environmental changes or system dynamics. Unlike digital twins, traditional models lack continuous data integration and real-time feedback, which restricts their accuracy and predictive capabilities in complex marine operations.

Data Integration: Real-Time vs Static Approaches

Digital twins integrate real-time data from IoT sensors, offering dynamic and continuous updates that enhance accuracy and predictive capabilities. Traditional modeling relies on static data sets, often outdated, resulting in less responsive and less precise simulations. Real-time data integration in digital twins enables immediate anomaly detection and adaptive decision-making, surpassing the limitations of conventional static models.

Accuracy and Predictive Capabilities Compared

Digital twin technology outperforms traditional modeling by offering real-time data integration, enhancing accuracy through continuous updates and reflecting actual system states. Traditional models rely on static assumptions and historical data, limiting their predictive capabilities and responsiveness to dynamic changes. The advanced simulation features of digital twins enable more precise forecasting and proactive decision-making in complex environments.

Operational Efficiency and Maintenance

Digital twin technology offers real-time data integration and predictive analytics, enhancing operational efficiency by enabling proactive maintenance and reducing downtime. Traditional modeling relies on static simulations, often lacking the dynamic feedback necessary for timely interventions and optimized asset performance. Leveraging IoT sensors and continuous data streams, digital twins facilitate condition-based maintenance and rapid fault detection, significantly improving equipment longevity and resource allocation.

Cost Implications and Return on Investment

Digital twin technology offers significant cost savings compared to traditional modeling by enabling real-time monitoring and predictive maintenance, reducing unplanned downtime and operational expenses. The dynamic nature of digital twins allows continuous optimization and faster decision-making, leading to higher return on investment (ROI) through improved asset utilization and performance. Traditional models often require costly manual updates and lack real-time data integration, resulting in slower response times and lower overall ROI.

Scalability and Implementation Challenges

Digital twin technology offers superior scalability compared to traditional modeling by enabling real-time data integration and dynamic system updates across multiple asset instances. Implementation challenges include the need for high-fidelity sensor data, advanced analytics infrastructure, and seamless IoT connectivity, which are less critical in static traditional models. Traditional modeling faces limitations in scalability due to its reliance on fixed parameters and lack of continuous feedback loops, resulting in slower adaptation to changing operational conditions.

Case Studies in Marine Engineering Applications

Digital twins in marine engineering provide real-time data integration and predictive analytics, enhancing vessel performance and maintenance compared to traditional modeling that relies on static simulations. Case studies demonstrate digital twin applications in optimizing hull design, fuel efficiency, and proactive fault detection, significantly reducing operational costs and downtime. Traditional models often lack dynamic feedback and fail to capture complex environmental interactions that digital twins effectively simulate for improved decision-making.

Future Trends: The Evolution of Modeling Technologies

Digital twin technology is revolutionizing future trends by enabling real-time data integration and dynamic simulation, surpassing traditional static modeling methods. Advances in IoT, AI, and machine learning are driving digital twins to offer predictive analytics and autonomous decision-making capabilities. The evolution of modeling technologies points towards increasingly interconnected and intelligent systems that optimize performance and maintenance across industries.

Real-time data integration

Digital twin technology outperforms traditional modeling by enabling continuous real-time data integration, enhancing accuracy and dynamic system monitoring.

Condition-based monitoring

Digital twins enable real-time condition-based monitoring by integrating live sensor data and predictive analytics, surpassing traditional modeling's static and periodic assessment capabilities.

Predictive maintenance algorithms

Digital twin technology leverages real-time sensor data and advanced predictive maintenance algorithms to outperform traditional modeling by enabling dynamic asset monitoring, anomaly detection, and optimized maintenance scheduling.

System-of-systems simulation

Digital twin technology enables real-time, dynamic system-of-systems simulation by integrating live data streams for predictive analytics, surpassing traditional modeling's static, isolated system representations.

Physics-based modeling

Digital twin technology enhances physics-based modeling by integrating real-time data and predictive analytics, offering dynamic and adaptive simulations compared to static and predefined outcomes in traditional physics-based models.

Virtual commissioning

Digital twin technology enhances virtual commissioning by enabling real-time, dynamic simulation and predictive analysis, surpassing traditional modeling's static representations and improving system optimization and fault detection.

Lifecycle asset management

Digital twin technology enhances lifecycle asset management by providing real-time data integration, predictive analytics, and dynamic simulation, outperforming traditional modeling's static and retrospective approaches.

Sensor fusion analytics

Digital twin technology leverages advanced sensor fusion analytics to integrate real-time multisource data, providing dynamic and accurate system simulations compared to static traditional modeling methods.

Computational fluid dynamics (CFD) visualization

Digital twin technology enables real-time, high-fidelity CFD visualization by integrating dynamic sensor data, outperforming traditional static CFD modeling in accuracy and predictive capabilities.

Legacy system interoperability

Digital twins enhance legacy system interoperability by providing real-time, dynamic simulation and integration capabilities that traditional modeling lacks.

Digital twin vs Traditional modeling Infographic

njnir.com

njnir.com