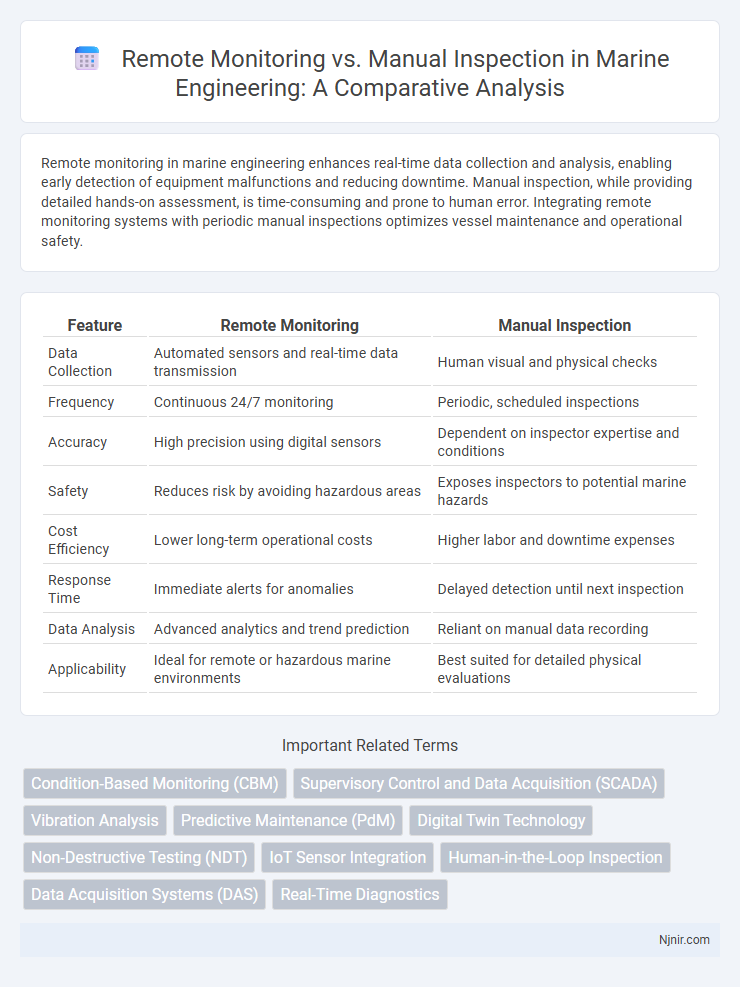

Remote monitoring in marine engineering enhances real-time data collection and analysis, enabling early detection of equipment malfunctions and reducing downtime. Manual inspection, while providing detailed hands-on assessment, is time-consuming and prone to human error. Integrating remote monitoring systems with periodic manual inspections optimizes vessel maintenance and operational safety.

Table of Comparison

| Feature | Remote Monitoring | Manual Inspection |

|---|---|---|

| Data Collection | Automated sensors and real-time data transmission | Human visual and physical checks |

| Frequency | Continuous 24/7 monitoring | Periodic, scheduled inspections |

| Accuracy | High precision using digital sensors | Dependent on inspector expertise and conditions |

| Safety | Reduces risk by avoiding hazardous areas | Exposes inspectors to potential marine hazards |

| Cost Efficiency | Lower long-term operational costs | Higher labor and downtime expenses |

| Response Time | Immediate alerts for anomalies | Delayed detection until next inspection |

| Data Analysis | Advanced analytics and trend prediction | Reliant on manual data recording |

| Applicability | Ideal for remote or hazardous marine environments | Best suited for detailed physical evaluations |

Introduction to Remote Monitoring and Manual Inspection in Marine Engineering

Remote monitoring in marine engineering utilizes advanced sensors and IoT technology to continuously track vessel performance, engine conditions, and environmental parameters, enabling real-time data analysis and predictive maintenance. Manual inspection relies on skilled engineers conducting physical checks, visual assessments, and diagnostic tests to identify wear, corrosion, and mechanical faults, often requiring vessel downtime. Integrating remote monitoring with manual inspection enhances operational efficiency, reduces maintenance costs, and improves safety by providing comprehensive and timely insights into marine systems.

Evolution of Inspection Methods in Marine Systems

Remote monitoring in marine systems leverages advanced sensors, IoT technology, and real-time data analytics to continuously track vessel performance, corrosion levels, and structural integrity, significantly reducing the need for physical presence. Manual inspection, traditionally reliant on skilled divers and technicians conducting visual and tactile assessments, remains essential for detailed evaluations where sensor data may be insufficient. The evolution from manual to remote techniques has optimized maintenance efficiency, enhanced safety, and expanded the scope of condition monitoring in marine environments.

Key Technologies in Remote Monitoring for Marine Applications

Key technologies in remote monitoring for marine applications include IoT sensors, underwater drones, and satellite communication systems, enabling real-time data acquisition on vessel conditions and marine environments. Advanced analytics platforms and AI-driven algorithms process sensor data to detect anomalies, predict maintenance needs, and enhance decision-making accuracy. Integration of cloud computing ensures seamless data storage and accessibility, optimizing operational efficiency compared to traditional manual inspection methods.

Traditional Manual Inspection: Techniques and Limitations

Traditional manual inspection involves physical examination methods such as visual checks, measurements, and tactile assessments conducted by skilled personnel. These techniques are time-consuming and prone to human error, leading to inconsistent data quality and potential safety risks. Manual inspections often require shutdowns or limited access, resulting in operational downtime and increased maintenance costs.

Accuracy and Reliability: Remote Monitoring vs Manual Inspection

Remote monitoring systems leverage advanced sensors and real-time data analytics, delivering higher accuracy and continuous reliability compared to manual inspections, which are vulnerable to human error and intermittent oversight. Data collected remotely enables timely detection of anomalies with consistent precision, reducing the risk of missed issues inherent in manual methods. While manual inspections depend on inspector skill and are limited by access and frequency, remote monitoring ensures comprehensive, objective, and repeatable accuracy across all monitored parameters.

Cost Implications and Operational Efficiency

Remote monitoring significantly reduces operational costs by minimizing the need for on-site personnel and enabling real-time data collection, which accelerates decision-making and issue resolution. Manual inspection involves higher labor expenses, increased downtime, and slower response times due to the physical presence required for assessments. Incorporating remote monitoring technology enhances operational efficiency through continuous surveillance and predictive maintenance, whereas manual inspection often limits scalability and increases the risk of human error.

Safety Considerations in Marine Inspections

Remote monitoring in marine inspections significantly enhances safety by reducing the need for personnel to access hazardous environments, minimizing exposure to rough seas and confined spaces. Manual inspections, while thorough, expose inspectors to risks such as slips, falls, and hazardous material contact, requiring stringent safety protocols and protective equipment. Incorporating advanced remote sensing technologies ensures continuous data collection, enabling early hazard detection without compromising human safety.

Data Collection and Analysis: Digital vs Human Insights

Remote monitoring leverages advanced sensors and IoT devices to continuously collect real-time data with high precision, enabling automated analysis through machine learning algorithms that detect patterns and anomalies faster than human capabilities. Manual inspection relies on human senses and judgment, providing qualitative insights and contextual understanding that are difficult to replicate digitally but are limited by subjectivity and less frequent data points. Combining digital data collection with human analysis can enhance overall decision-making by integrating precise quantitative metrics and nuanced qualitative observations.

Environmental Impact of Inspection Methods

Remote monitoring significantly reduces the environmental footprint by minimizing the need for travel and on-site visits, lowering carbon emissions compared to traditional manual inspections. It enables continuous data collection through sensors and IoT devices, promoting proactive maintenance and reducing resource-intensive interventions. Manual inspection often involves frequent physical inspections that increase fuel consumption and disturbances to natural habitats, making remote monitoring a more sustainable and eco-friendly option.

Future Trends in Marine Inspection and Maintenance

Remote monitoring leverages advanced IoT sensors and real-time data analytics to enhance predictive maintenance and reduce downtime in marine operations. Manual inspection remains critical for detecting complex structural issues but is increasingly complemented by autonomous drones and robotic systems that improve safety and efficiency. Future trends emphasize integrating AI-powered remote monitoring platforms with augmented reality tools to provide inspectors with comprehensive situational awareness and decision support.

Condition-Based Monitoring (CBM)

Remote monitoring enables real-time, continuous Condition-Based Monitoring (CBM) that improves accuracy and reduces downtime compared to periodic, labor-intensive manual inspections.

Supervisory Control and Data Acquisition (SCADA)

SCADA systems enable real-time remote monitoring and automated data collection, significantly improving efficiency and accuracy compared to traditional manual inspection methods.

Vibration Analysis

Vibration analysis using remote monitoring provides continuous, real-time data for early fault detection, surpassing the intermittent and subjective nature of manual inspection methods.

Predictive Maintenance (PdM)

Remote monitoring leverages real-time sensor data and AI analytics to enable predictive maintenance by detecting equipment failures before they occur, whereas manual inspection relies on periodic human assessments that may miss early signs of deterioration.

Digital Twin Technology

Digital Twin Technology enables remote monitoring by creating real-time virtual replicas of physical assets, significantly enhancing inspection accuracy and reducing the need for manual inspections.

Non-Destructive Testing (NDT)

Remote monitoring in Non-Destructive Testing (NDT) enhances accuracy and efficiency by using real-time sensor data, whereas manual inspection relies on physical examination, which is time-consuming and prone to human error.

IoT Sensor Integration

IoT sensor integration enables continuous remote monitoring by providing real-time data analytics and predictive maintenance, significantly outperforming traditional manual inspections in accuracy and efficiency.

Human-in-the-Loop Inspection

Human-in-the-Loop Inspection integrates remote monitoring with manual inspection to enhance accuracy and real-time decision-making in complex systems.

Data Acquisition Systems (DAS)

Remote monitoring using advanced Data Acquisition Systems (DAS) enables continuous, real-time data collection and analysis, significantly enhancing accuracy and efficiency compared to periodic manual inspection methods.

Real-Time Diagnostics

Remote monitoring provides real-time diagnostics by continuously analyzing data through sensors and software, enabling immediate detection of anomalies, whereas manual inspection relies on periodic, human-initiated checks often resulting in delayed issue identification.

Remote monitoring vs Manual inspection Infographic

njnir.com

njnir.com