Waterjet propulsion offers superior maneuverability and shallow water operation compared to conventional propellers, minimizing damage risks and enhancing safety. The absence of exposed blades reduces cavitation and lowers maintenance costs while delivering high-speed efficiency for various marine vessels. Conventional propellers, however, provide better fuel efficiency at lower speeds, making them suitable for larger ships and heavy-duty marine applications.

Table of Comparison

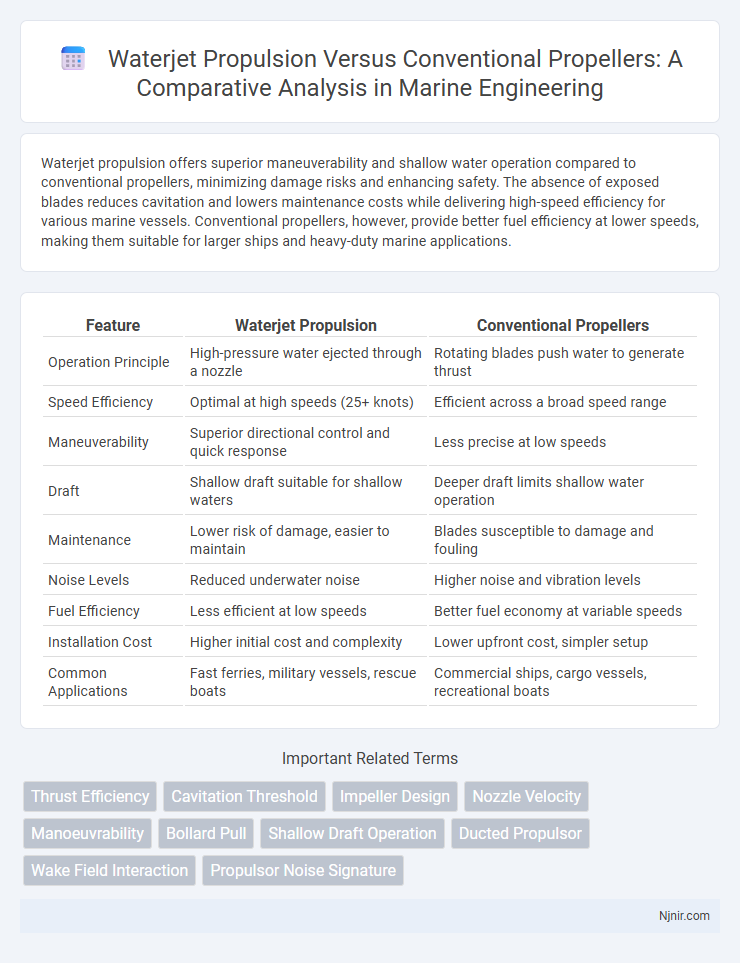

| Feature | Waterjet Propulsion | Conventional Propellers |

|---|---|---|

| Operation Principle | High-pressure water ejected through a nozzle | Rotating blades push water to generate thrust |

| Speed Efficiency | Optimal at high speeds (25+ knots) | Efficient across a broad speed range |

| Maneuverability | Superior directional control and quick response | Less precise at low speeds |

| Draft | Shallow draft suitable for shallow waters | Deeper draft limits shallow water operation |

| Maintenance | Lower risk of damage, easier to maintain | Blades susceptible to damage and fouling |

| Noise Levels | Reduced underwater noise | Higher noise and vibration levels |

| Fuel Efficiency | Less efficient at low speeds | Better fuel economy at variable speeds |

| Installation Cost | Higher initial cost and complexity | Lower upfront cost, simpler setup |

| Common Applications | Fast ferries, military vessels, rescue boats | Commercial ships, cargo vessels, recreational boats |

Introduction to Marine Propulsion Systems

Marine propulsion systems are essential for converting engine power into thrust, enabling vessel movement through water. Waterjet propulsion systems utilize high-pressure water jets to produce thrust, offering enhanced maneuverability and shallow draft advantages compared to conventional propellers. Conventional propellers rely on rotating blades to generate thrust, providing efficient propulsion for a wide range of vessel speeds and sizes but with limitations in debris-prone or shallow environments.

Fundamentals of Waterjet Propulsion

Waterjet propulsion operates by drawing water into a pump and expelling it at high velocity through a nozzle, generating thrust without exposed rotating blades. This method offers increased maneuverability, reduced draft, and enhanced safety compared to conventional propellers that rely on spinning blades submerged in water. The core principle involves Newton's third law, where the rapid ejection of water creates a reactive force propelling the vessel forward efficiently at high speeds.

Conventional Propeller Technology Explained

Conventional propeller technology operates by converting rotational energy from an engine into thrust through the blades pushing against water, creating forward motion. These propellers vary in size, number of blades, and pitch, optimizing performance for different vessel types and speeds, with common materials including bronze and stainless steel for durability and corrosion resistance. Efficiency in conventional propellers depends on factors such as blade shape, diameter, and revolutions per minute, making them widely used in maritime applications from small boats to large ships due to their proven reliability and effectiveness in various water conditions.

Efficiency Comparison: Waterjets vs Propellers

Waterjet propulsion systems offer higher efficiency at high speeds due to reduced drag and improved maneuverability compared to conventional propellers. Conventional propellers typically achieve better fuel efficiency at lower speeds and in steady cruising conditions, benefiting from optimized blade designs and established hydrodynamic performance. Efficiency comparisons depend significantly on vessel type, operational profile, and speed range, with waterjets favored for rapid response and shallow draft operations while propellers excel in fuel economy during extended, moderate-speed voyages.

Maneuverability and Handling Differences

Waterjet propulsion offers superior maneuverability compared to conventional propellers by providing rapid and precise directional control through vectored thrust, which enhances handling in shallow waters and tight spaces. Unlike traditional propellers that rely on rudders for steering, waterjets enable instantaneous changes in thrust direction, allowing for tighter turns and quicker stopping distances. This technology reduces the risk of damage from underwater obstacles, making it ideal for vessels requiring high agility and responsiveness.

Cavitation Risks and Control Methods

Waterjet propulsion significantly reduces cavitation risks compared to conventional propellers by utilizing high-speed water jets that minimize pressure differentials responsible for vapor bubble formation. Conventional propellers often experience cavitation due to blade tip vortices and pressure drops, leading to noise, vibration, and potential damage. Control methods for waterjets include variable geometry nozzles and adjustable flow rates, while conventional propellers rely on blade pitch adjustments and anti-cavitation designs to manage cavitation effects.

Shallow Water Performance

Waterjet propulsion offers superior shallow water performance by minimizing the risk of damage from underwater obstacles due to its enclosed intake system, unlike conventional propellers which are exposed and more vulnerable. Waterjets provide enhanced maneuverability and higher acceleration in shallow waters, making them ideal for applications requiring frequent changes in direction. Propeller-driven vessels often struggle with draft limitations and increased maintenance costs in shallow environments, where waterjets maintain efficiency and reliability.

Maintenance Requirements and Lifespan

Waterjet propulsion systems typically require less maintenance than conventional propellers because they have fewer exposed moving parts and no external blades vulnerable to damage, reducing wear and repair frequency. The lifespan of waterjet units is generally longer, especially in shallow or debris-filled waters, as their enclosed impellers avoid impacts and corrosion that commonly degrade propeller blades. Conventional propellers often demand regular inspections, blade repairs, and shaft alignment due to exposure to marine hazards, which can shorten their operational lifespan compared to waterjets.

Applications and Vessel Suitability

Waterjet propulsion suits high-speed vessels like patrol boats, rescue crafts, and passenger ferries that require superior maneuverability and shallow draft operation. Conventional propellers remain preferred for cargo ships, fishing boats, and bulk carriers due to their efficiency at lower speeds and simpler maintenance. Vessel suitability depends on operational requirements; waterjets excel in agility and reduced underwater noise, while propellers deliver better fuel efficiency and thrust in heavy-duty, low-speed applications.

Future Trends in Marine Propulsion

Waterjet propulsion systems are gaining traction due to their superior maneuverability, reduced underwater noise, and enhanced safety compared to conventional propellers, making them ideal for high-speed vessels and environmentally sensitive areas. Advanced materials and integration with hybrid-electric technologies are accelerating the adoption of waterjets, contributing to improved fuel efficiency and lower emissions in marine propulsion. Future trends emphasize smart propulsion systems with real-time performance monitoring and adaptive thrust control, positioning waterjet technology as a key driver in sustainable and innovative marine transport solutions.

Thrust Efficiency

Waterjet propulsion delivers higher thrust efficiency at high speeds and shallow waters by minimizing cavitation and drag compared to conventional propellers.

Cavitation Threshold

Waterjet propulsion systems exhibit a higher cavitation threshold compared to conventional propellers, reducing blade erosion and improving performance in shallow waters.

Impeller Design

Waterjet propulsion utilizes a closed impeller design that enhances thrust efficiency and maneuverability compared to the open-blade configuration of conventional propellers, resulting in improved high-speed performance and reduced cavitation.

Nozzle Velocity

Waterjet propulsion generates higher nozzle velocity than conventional propellers, resulting in improved maneuverability and reduced cavitation risk.

Manoeuvrability

Waterjet propulsion offers superior maneuverability compared to conventional propellers by providing rapid directional changes and enhanced control in shallow or confined waters.

Bollard Pull

Waterjet propulsion delivers higher bollard pull efficiency at low speeds compared to conventional propellers, enhancing vessel maneuverability and thrust in shallow or debris-laden waters.

Shallow Draft Operation

Waterjet propulsion offers superior shallow draft operation compared to conventional propellers by minimizing underwater appendage depth and reducing the risk of damage in shallow waters.

Ducted Propulsor

Ducted propulsors in waterjet propulsion systems offer enhanced maneuverability, increased thrust efficiency, and reduced cavitation compared to conventional open propellers, making them ideal for high-speed marine vessels.

Wake Field Interaction

Waterjet propulsion generates a significantly reduced wake field interaction compared to conventional propellers, enhancing maneuverability and minimizing underwater disturbance in marine vessels.

Propulsor Noise Signature

Waterjet propulsion produces significantly lower propulsor noise signature compared to conventional propellers due to reduced blade cavitation and smoother water flow.

Waterjet Propulsion vs Conventional Propellers Infographic

njnir.com

njnir.com