Direct drive propulsion in marine engineering offers higher efficiency and reduced mechanical complexity by connecting the engine directly to the propeller shaft, minimizing energy losses. Geared drive systems use reduction gears to optimize engine speed and propeller rotation, enhancing fuel efficiency and allowing smaller, high-speed engines. Choosing between direct drive and geared drive depends on vessel size, operational profile, and maintenance considerations.

Table of Comparison

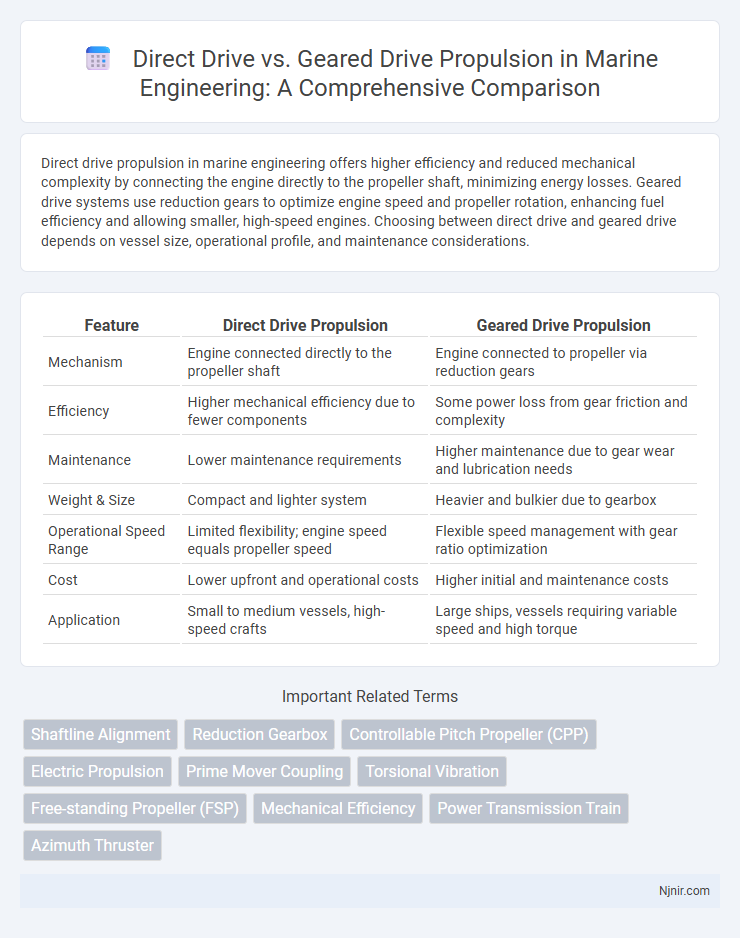

| Feature | Direct Drive Propulsion | Geared Drive Propulsion |

|---|---|---|

| Mechanism | Engine connected directly to the propeller shaft | Engine connected to propeller via reduction gears |

| Efficiency | Higher mechanical efficiency due to fewer components | Some power loss from gear friction and complexity |

| Maintenance | Lower maintenance requirements | Higher maintenance due to gear wear and lubrication needs |

| Weight & Size | Compact and lighter system | Heavier and bulkier due to gearbox |

| Operational Speed Range | Limited flexibility; engine speed equals propeller speed | Flexible speed management with gear ratio optimization |

| Cost | Lower upfront and operational costs | Higher initial and maintenance costs |

| Application | Small to medium vessels, high-speed crafts | Large ships, vessels requiring variable speed and high torque |

Overview of Marine Propulsion Systems

Marine propulsion systems primarily use either direct drive or geared drive configurations to convert engine power into thrust. Direct drive systems connect the engine shaft directly to the propeller, offering higher efficiency and simpler maintenance suitable for lower to medium power applications. Geared drive systems employ reduction gears to adjust engine output speed to optimal propeller speed, enhancing performance and fuel economy in high-power vessels such as commercial ships and large yachts.

Understanding Direct Drive Propulsion

Direct drive propulsion systems eliminate the need for gears, connecting the motor shaft directly to the propeller or wheel, resulting in higher mechanical efficiency and reduced maintenance requirements. These systems offer smoother acceleration, less noise, and lower energy losses compared to geared drives, making them ideal for electric vehicles and marine applications. Direct drive units often feature simplified designs with fewer moving parts, enhancing reliability and extending operational life.

Geared Drive Propulsion Explained

Geared drive propulsion uses a gearbox to transfer power from the engine to the propeller, optimizing rotational speed and torque for improved efficiency and performance. This system allows the engine to operate at higher RPMs while maintaining propeller speed within optimal limits, reducing vibration and fuel consumption. Geared drives are particularly advantageous in applications requiring high power density and smoother, quieter operation compared to direct drive systems.

Efficiency Comparison: Direct vs Geared Drives

Direct drive propulsion systems demonstrate higher mechanical efficiency due to fewer moving parts and reduced friction losses compared to geared drives, which incur energy loss through gear meshing and additional components. Geared drives offer torque multiplication and versatility but typically exhibit lower overall energy efficiency, especially under variable speed conditions. Studies show direct drives can achieve efficiency rates above 90%, whereas geared counterparts often range between 80-85%, making direct drives preferable for energy-sensitive applications.

Maintenance Requirements and Costs

Direct drive propulsion systems typically require less maintenance due to fewer moving parts and the elimination of gears, reducing overall downtime and repair costs. Geared drive systems, while often more complex, necessitate regular inspection, lubrication, and potential replacement of gear components, leading to higher maintenance efforts and expenses. The simplicity of direct drives translates to lower long-term operational costs compared to the more maintenance-intensive geared drives.

Performance at Different Operating Speeds

Direct drive propulsion systems deliver consistent torque and efficiency across a wide range of operating speeds, making them ideal for high-speed applications and smooth acceleration. Geared drive systems optimize power output at specific speed ranges by using gear ratios, which can enhance torque at low speeds but may introduce mechanical losses at higher speeds. Performance differences emphasize the trade-off between the simplicity and direct power transfer of direct drives and the customizable torque-speed characteristics of geared drives.

Space and Weight Considerations

Direct drive propulsion systems significantly reduce weight by eliminating complex gear assemblies, which is critical for spacecraft aiming to maximize payload capacity. Geared drives, while heavier, offer torque multiplication that can enable smaller motors but add mass and potential points of failure. In space applications, the weight savings and mechanical simplicity of direct drive translate to enhanced reliability and improved fuel efficiency.

Reliability and Durability Factors

Direct drive propulsion systems offer higher reliability due to fewer moving parts, reducing wear and maintenance needs compared to geared drive systems that involve multiple gears prone to mechanical failure. The simplicity of direct drive enhances durability by minimizing stress points and heat generation, extending the lifespan of critical components. Geared drive propulsion, while offering torque multiplication, faces potential durability challenges from gear wear, lubrication issues, and alignment sensitivity impacting long-term reliability.

Environmental Impact and Fuel Consumption

Direct drive propulsion systems generally offer higher energy efficiency and lower fuel consumption compared to geared drive systems due to reduced mechanical losses and fewer moving parts. This increased efficiency translates into a smaller carbon footprint and decreased greenhouse gas emissions, making direct drives more environmentally friendly. Geared drives, while often cheaper and easier to maintain, typically result in higher fuel usage and greater environmental impact due to energy lost through gear friction and increased maintenance needs.

Applications and Suitability in Marine Vessels

Direct drive propulsion offers higher efficiency and lower maintenance, making it ideal for high-speed vessels and applications requiring rapid acceleration like patrol boats and fast ferries. Geared drive propulsion suits larger ships such as cargo vessels and tankers, providing enhanced torque and better fuel economy at lower speeds due to the gearbox's ability to optimize engine performance. Both systems impact vessel design, operational costs, and mission profiles, with direct drive favored in performance-critical roles and geared drives preferred for heavy-duty, long-distance maritime operations.

Shaftline Alignment

Direct drive propulsion systems offer superior shaftline alignment by minimizing mechanical components and reducing misalignment risks compared to geared drive systems.

Reduction Gearbox

Reduction gearboxes in geared drive propulsion systems optimize torque transmission by lowering motor speed to increase torque, enhancing efficiency and reliability compared to direct drive systems.

Controllable Pitch Propeller (CPP)

Direct drive propulsion systems enhance Controllable Pitch Propeller (CPP) efficiency by providing smoother torque transmission and reduced mechanical losses compared to geared drive systems, which often introduce complexity and maintenance challenges.

Electric Propulsion

Direct drive electric propulsion offers higher efficiency and lower maintenance compared to geared drive systems by eliminating the gearbox and reducing mechanical losses.

Prime Mover Coupling

Direct drive propulsion systems feature a prime mover coupling that connects the engine directly to the drivetrain, eliminating energy losses associated with gear reduction found in geared drive systems.

Torsional Vibration

Direct drive propulsion systems reduce torsional vibration by eliminating gear mesh frequencies, while geared drive systems often require advanced dampers to mitigate torsional vibrations caused by gear interaction.

Free-standing Propeller (FSP)

Direct drive propulsion enhances Free-standing Propeller (FSP) efficiency by reducing mechanical losses and maintenance compared to geared drive systems.

Mechanical Efficiency

Direct drive propulsion offers higher mechanical efficiency by minimizing energy losses through fewer moving parts compared to geared drive systems, which experience efficiency reductions due to gear friction and heat.

Power Transmission Train

Direct drive propulsion features a simplified power transmission train with fewer components and reduced mechanical losses, while geared drive propulsion relies on complex gear systems that increase torque conversion efficiency but add weight and maintenance requirements.

Azimuth Thruster

Azimuth thrusters with direct drive propulsion offer higher efficiency and reduced maintenance compared to geared drive systems by eliminating gear losses and providing instant thrust vectoring for enhanced maneuverability.

direct drive vs geared drive propulsion Infographic

njnir.com

njnir.com