Dynamic positioning systems use advanced sensors and thrusters to maintain a vessel's position automatically despite wind, waves, and current, enhancing precision and safety in complex marine operations. Manual anchoring relies on traditional methods of dropping and securing anchors, which are dependent on seabed conditions and can be less reliable in deep waters or turbulent environments. This technology reduces the risk of drifting, ensures operational efficiency, and minimizes environmental impact compared to conventional manual anchoring techniques.

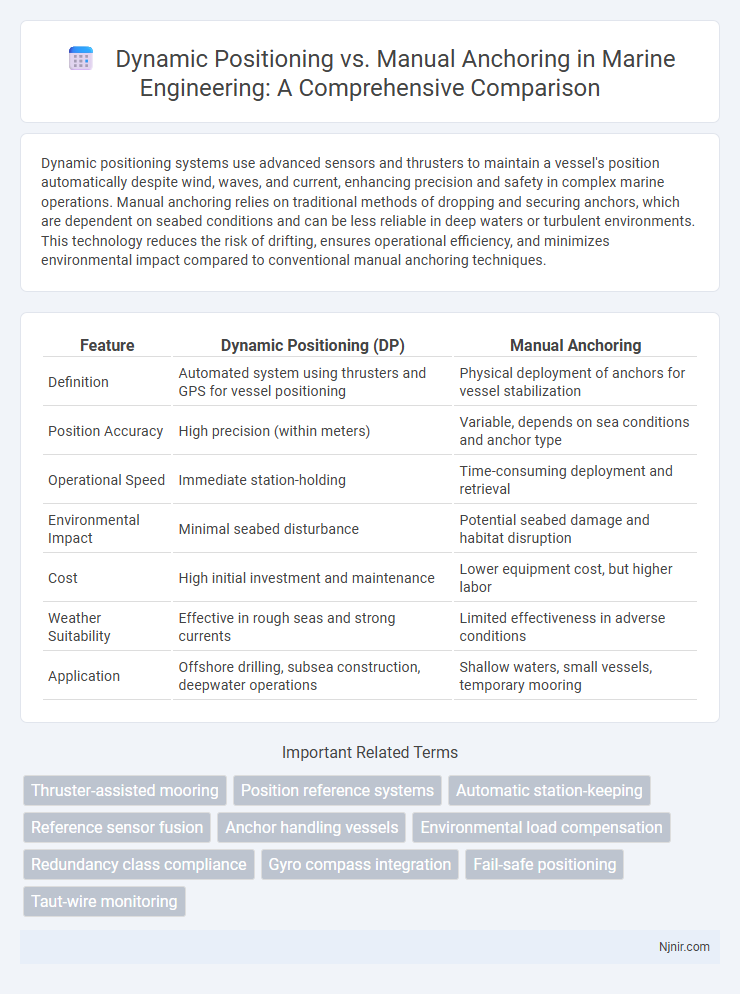

Table of Comparison

| Feature | Dynamic Positioning (DP) | Manual Anchoring |

|---|---|---|

| Definition | Automated system using thrusters and GPS for vessel positioning | Physical deployment of anchors for vessel stabilization |

| Position Accuracy | High precision (within meters) | Variable, depends on sea conditions and anchor type |

| Operational Speed | Immediate station-holding | Time-consuming deployment and retrieval |

| Environmental Impact | Minimal seabed disturbance | Potential seabed damage and habitat disruption |

| Cost | High initial investment and maintenance | Lower equipment cost, but higher labor |

| Weather Suitability | Effective in rough seas and strong currents | Limited effectiveness in adverse conditions |

| Application | Offshore drilling, subsea construction, deepwater operations | Shallow waters, small vessels, temporary mooring |

Introduction to Dynamic Positioning and Manual Anchoring

Dynamic positioning (DP) is an advanced ship control system that uses computer-controlled thrusters and propellers guided by sensors and GPS to maintain a vessel's precise position and heading automatically. Manual anchoring involves physically deploying and setting anchors by crew members to secure a vessel in place, relying heavily on human judgment and environmental conditions. DP provides superior accuracy, adaptability to changing sea conditions, and reduces reliance on seabed suitability compared to manual anchoring.

Fundamentals of Dynamic Positioning Systems

Dynamic positioning systems use computer-controlled thrusters and sensors to maintain a vessel's position and heading automatically despite environmental forces such as wind, waves, and currents. In contrast, manual anchoring relies on physically lowering anchors to grip the seabed, which is limited by seabed conditions and requires crew intervention for stability. The fundamentals of dynamic positioning include GPS, gyrocompasses, wind sensors, and control algorithms that continuously adjust thrust to keep the vessel precisely in place without physical anchoring.

Principles of Manual Anchoring Techniques

Manual anchoring relies on accurate seabed assessment, precise rope handling, and controlled vessel positioning to ensure secure holding. Key principles include selecting appropriate anchor types, managing scope ratio between anchor line length and water depth, and monitoring environmental forces like wind and current. Mastery of these techniques minimizes drag and prevents anchor dragging, ensuring vessel stability without dynamic positioning systems.

Operational Efficiency: Dynamic Positioning vs Manual Anchoring

Dynamic positioning enhances operational efficiency by using advanced sensors and computer systems to maintain vessel position automatically, reducing human error and increasing precision compared to manual anchoring. Manual anchoring relies on physical anchors and crew intervention, which can be time-consuming, less accurate, and susceptible to environmental challenges like currents and seabed conditions. Automated systems in dynamic positioning optimize fuel consumption and operational uptime, making it ideal for complex marine operations requiring high stability and responsiveness.

Safety Considerations in Position-Keeping Methods

Dynamic positioning systems provide enhanced safety by continuously monitoring vessel position using GPS, gyrocompasses, and thrusters, reducing risks of drift in challenging conditions. Manual anchoring depends heavily on crew expertise and environmental factors like seabed type and weather, increasing potential for anchor drag or failure. Automated alerts and redundancy in dynamic positioning further minimize human error, making it a safer choice for critical offshore operations.

Technological Requirements and Integration

Dynamic positioning systems require advanced sensors, GPS, thrusters, and sophisticated control software to maintain vessel stability without physical anchors, integrating seamlessly with onboard navigation and automation systems. Manual anchoring depends on traditional mechanical equipment like anchors, chains, and winches, demanding minimal technological infrastructure but requiring manual operation and positioning skills. Integration complexity is significantly higher for dynamic positioning, involving real-time data processing and system synchronization to ensure precise station-keeping in diverse marine environments.

Environmental Impact and Sustainability

Dynamic positioning systems significantly reduce seabed disturbance and marine habitat destruction compared to manual anchoring, which often leads to physical damage and sediment disruption. By minimizing contact with the seabed and reducing anchor dragging, dynamic positioning supports sustainable marine operations and helps preserve biodiversity. Energy consumption and emissions vary between the two methods, with optimized dynamic positioning systems increasingly integrating energy-efficient technologies to lessen environmental footprints.

Cost Comparison: Installation, Operation, and Maintenance

Dynamic positioning (DP) systems typically incur higher installation costs due to sophisticated sensors, thrusters, and control software compared to manual anchoring's reliance on traditional anchors and winches. Operational expenses for DP include continuous energy consumption and specialized crew training, while manual anchoring requires less fuel but may increase labor intensity and time. Maintenance costs for DP involve complex electronic systems and periodic updates, whereas manual anchoring demands regular inspection and repair of mechanical anchor components, often resulting in lower maintenance expenditures.

Application Scenarios and Industry Preferences

Dynamic positioning is preferred in offshore oil and gas drilling, deepwater exploration, and renewable energy installations due to its precision and ability to maintain position without physical anchors, especially in deep or congested waters. Manual anchoring remains common in coastal fishing, smaller vessels, and regions with suitable seabed conditions where cost-effectiveness and simplicity are prioritized. The offshore maritime industry increasingly favors dynamic positioning systems for complex operations, while traditional anchoring persists in commercial shipping and recreational boating sectors.

Future Trends in Marine Positioning Systems

Dynamic positioning systems are rapidly advancing with integration of AI and machine learning to enhance precision and fuel efficiency, outperforming traditional manual anchoring methods in complex marine environments. Future trends indicate widespread adoption of hybrid positioning systems that combine GPS, inertial navigation, and real-time environmental data, reducing human error and operational downtime. Innovations such as autonomous vessel control and enhanced sensor fusion are set to redefine marine positioning accuracy and safety standards.

Thruster-assisted mooring

Dynamic positioning uses computer-controlled thrusters for precise vessel station-keeping, while manual anchoring relies on crew-operated anchors without thruster-assisted mooring, limiting responsiveness and accuracy.

Position reference systems

Dynamic positioning uses advanced GNSS and sensor-based position reference systems for automatic, real-time vessel stabilization, while manual anchoring relies on physical anchors and visual or traditional navigational references for positioning.

Automatic station-keeping

Dynamic positioning provides precise automatic station-keeping through GPS and thruster control, eliminating the need for manual anchoring and enhancing operational efficiency.

Reference sensor fusion

Dynamic positioning leverages advanced reference sensor fusion combining GPS, gyrocompasses, and motion sensors for precise vessel control, outperforming manual anchoring which relies solely on traditional visual and manual techniques.

Anchor handling vessels

Anchor handling vessels utilize dynamic positioning systems to maintain precise station-keeping in challenging sea conditions, significantly improving operational efficiency and safety compared to manual anchoring methods.

Environmental load compensation

Dynamic positioning systems continuously adjust thrust and heading to counteract environmental loads such as wind, waves, and currents, providing precise station-keeping compared to the fixed resistance offered by manual anchoring.

Redundancy class compliance

Dynamic positioning systems ensure continuous operational safety by adhering to higher redundancy class compliance standards compared to manual anchoring, which typically lacks systematic redundancy measures.

Gyro compass integration

Dynamic positioning systems integrate gyro compasses for precise vessel orientation and automatic station-keeping, while manual anchoring relies on gyro compass data solely for navigational reference without automated control.

Fail-safe positioning

Dynamic positioning uses advanced sensors and thrusters for continuous fail-safe positioning, whereas manual anchoring relies on physical anchors, which may be less reliable in adverse conditions.

Taut-wire monitoring

Dynamic positioning systems precisely maintain vessel position using Taut-wire monitoring, providing higher accuracy and automated control compared to the manual adjustments required in manual anchoring.

Dynamic positioning vs Manual anchoring Infographic

njnir.com

njnir.com