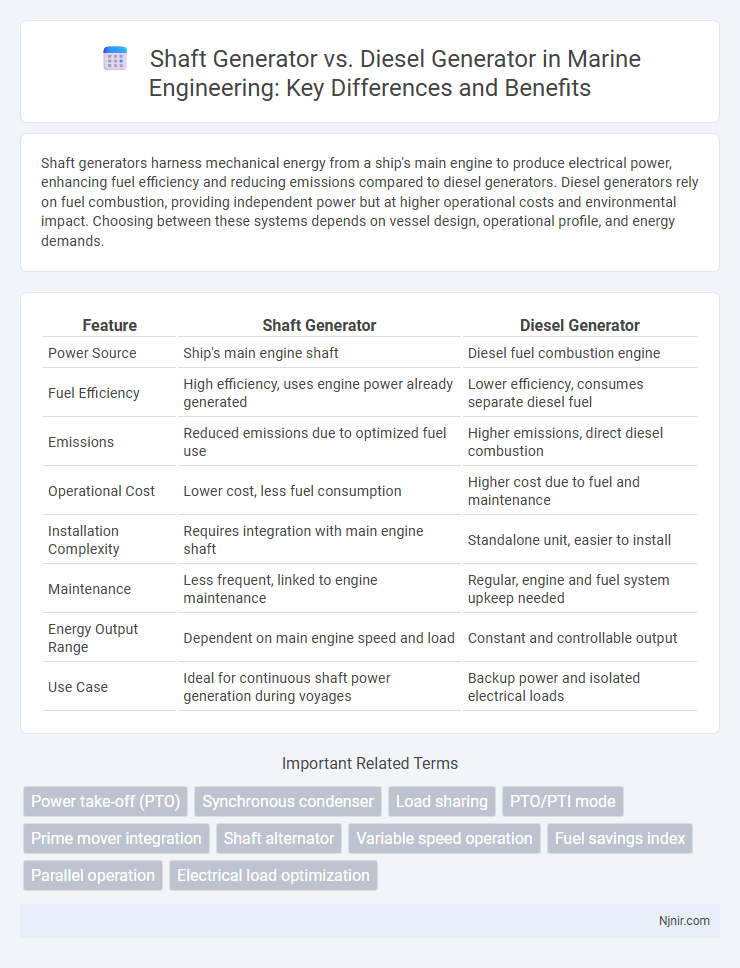

Shaft generators harness mechanical energy from a ship's main engine to produce electrical power, enhancing fuel efficiency and reducing emissions compared to diesel generators. Diesel generators rely on fuel combustion, providing independent power but at higher operational costs and environmental impact. Choosing between these systems depends on vessel design, operational profile, and energy demands.

Table of Comparison

| Feature | Shaft Generator | Diesel Generator |

|---|---|---|

| Power Source | Ship's main engine shaft | Diesel fuel combustion engine |

| Fuel Efficiency | High efficiency, uses engine power already generated | Lower efficiency, consumes separate diesel fuel |

| Emissions | Reduced emissions due to optimized fuel use | Higher emissions, direct diesel combustion |

| Operational Cost | Lower cost, less fuel consumption | Higher cost due to fuel and maintenance |

| Installation Complexity | Requires integration with main engine shaft | Standalone unit, easier to install |

| Maintenance | Less frequent, linked to engine maintenance | Regular, engine and fuel system upkeep needed |

| Energy Output Range | Dependent on main engine speed and load | Constant and controllable output |

| Use Case | Ideal for continuous shaft power generation during voyages | Backup power and isolated electrical loads |

Introduction to Shaft Generators and Diesel Generators

Shaft generators convert mechanical energy from a ship's main engine shaft into electrical power, offering fuel-efficient electricity generation during vessel operation. Diesel generators use internal combustion engines fueled by diesel to produce electrical power independently of the main propulsion system, providing reliable backup or primary power on ships and remote locations. The choice between shaft and diesel generators depends on operational efficiency, fuel consumption, and power demand dynamics.

Working Principle of Shaft Generators

Shaft generators operate by converting mechanical energy from a ship's main engine shaft into electrical power, using a rotary electrical machine coupled directly to the propulsion shaft. This method allows the generator to produce electricity efficiently when the ship is underway, utilizing the rotational energy already present. In contrast, diesel generators rely on internal combustion engines burning fuel to drive an alternator, generating electricity independently of the ship's propulsion system.

Working Principle of Diesel Generators

Diesel generators operate by burning diesel fuel to power an internal combustion engine, which drives an alternator to produce electrical energy. The engine converts chemical energy from diesel into mechanical energy through controlled combustion cycles, enabling consistent power generation. This process is distinct from shaft generators, which harness mechanical energy directly from a ship's main engine shaft to generate electricity.

Key Differences Between Shaft and Diesel Generators

Shaft generators utilize the mechanical energy from a ship's main engine to produce electricity, making them highly efficient and fuel-saving during vessel operation. Diesel generators operate independently using combustion engines, providing flexible power supply but with higher fuel consumption and maintenance costs. Key differences include energy source dependency, operational efficiency, and environmental impact, with shaft generators offering greener power generation compared to diesel generators.

Energy Efficiency Comparison

Shaft generators harness mechanical energy directly from a ship's main engine shaft, converting it into electrical power with efficiency rates typically above 90%, reducing fuel consumption and emissions. Diesel generators operate independently, relying on combustion engines that often exhibit lower energy efficiency, around 30-40%, due to energy loss in heat and friction. In maritime applications, shaft generators provide a more sustainable and cost-effective energy solution by optimizing fuel use and minimizing operational costs compared to conventional diesel generators.

Installation and Space Requirements

Shaft generators integrate directly with a ship's main engine shaft, significantly reducing the need for additional installation space compared to diesel generators, which require separate engine rooms and ventilation systems. The compact design of shaft generators minimizes onboard space consumption and simplifies integration, making them ideal for vessels with limited engine room capacity. Diesel generators demand substantial clearance for maintenance and fuel storage, resulting in larger spatial requirements during installation.

Operational Costs and Maintenance

Shaft generators typically have lower operational costs compared to diesel generators due to their integration with the ship's prime mover, reducing fuel consumption and minimizing wear on auxiliary engines. Maintenance for shaft generators is generally less frequent and less costly since they have fewer moving parts and benefit from the existing engine's lubrication system. Diesel generators require regular fuel, oil changes, and component replacements, resulting in higher ongoing maintenance expenses and downtime.

Environmental Impact and Emissions

Shaft generators harness mechanical energy from a ship's main engine, significantly reducing fuel consumption and cutting emissions like CO2, NOx, and particulate matter compared to diesel generators that rely on burning fuel separately. Diesel generators emit higher levels of greenhouse gases and air pollutants due to their dependence on fossil fuels, contributing to environmental degradation and stricter regulatory challenges. Shaft generators support cleaner maritime operations through improved fuel efficiency and lower carbon footprints, aligning with international emission reduction standards such as IMO Tier III.

Suitability for Different Vessel Types

Shaft generators are ideal for large commercial vessels like container ships and bulk carriers, as they efficiently convert mechanical energy from the main engine into electrical power, reducing fuel consumption and emissions during cruising. Diesel generators offer greater flexibility and are better suited for smaller vessels, offshore platforms, and vessels requiring independent power supply regardless of engine operation. The choice between shaft and diesel generators depends on vessel size, operational profile, and specific power demand patterns for optimized energy management.

Future Trends in Marine Power Generation

Shaft generators, integrated with a ship's main engine, offer improved fuel efficiency and lower emissions compared to traditional diesel generators, aligning with stringent maritime environmental regulations. Emerging trends include the hybridization of shaft and diesel generators combined with renewable energy sources to enhance energy resilience and reduce greenhouse gas emissions. Advances in digital monitoring and smart grid technology are driving optimized power management, ensuring a sustainable transition towards greener marine power generation.

Power take-off (PTO)

Shaft generators harness mechanical energy directly from a ship's propulsion shaft for efficient power take-off (PTO), while diesel generators rely on fuel combustion and independent engines, resulting in differing PTO mechanisms and energy conversion efficiencies.

Synchronous condenser

A shaft generator provides efficient onboard power by utilizing the ship's propulsion shaft for energy conversion, while a diesel generator offers independent power generation with a synchronous condenser function for reactive power compensation and voltage stability.

Load sharing

Shaft generators efficiently share load with diesel generators by utilizing engine power for electrical output during vessel operation, reducing fuel consumption and emissions.

PTO/PTI mode

Shaft generators provide efficient power generation from a vessel's main engine in PTO mode, while diesel generators offer flexible, independent power supply especially valuable in PTI mode during low engine load or zero-speed operations.

Prime mover integration

Shaft generators integrate directly with a ship's main engine, converting mechanical energy into electrical power, whereas diesel generators operate independently with separate prime movers, offering flexibility but less direct energy efficiency.

Shaft alternator

A shaft alternator in a shaft generator system efficiently converts mechanical energy from a ship's engine shaft into electrical power, offering lower fuel consumption and reduced emissions compared to a diesel generator.

Variable speed operation

Shaft generators excel in variable speed operation by directly harnessing engine RPM fluctuations for efficient power generation, whereas diesel generators typically require constant speeds for optimal performance and fuel efficiency.

Fuel savings index

Shaft generators deliver up to 30% greater fuel savings compared to diesel generators by utilizing ship engine power for electricity generation.

Parallel operation

Shaft generators seamlessly integrate with ship engines for parallel operation, optimizing fuel efficiency and reducing emissions compared to independent diesel generators.

Electrical load optimization

Shaft generators optimize electrical load by harnessing engine power for continuous electricity supply, reducing fuel consumption and emissions compared to diesel generators that rely on separate fuel combustion and often cause higher operational costs.

Shaft generator vs Diesel generator Infographic

njnir.com

njnir.com