Inline scrubbers offer a compact design that integrates seamlessly into existing piping systems, making them ideal for vessels with limited space. U-type scrubbers provide enhanced gas-liquid contact and increased removal efficiency due to their U-shaped configuration, which maximizes scrubbing liquid retention time. Both scrubber types play crucial roles in reducing sulfur oxide emissions, but the choice depends on vessel design constraints and operational requirements.

Table of Comparison

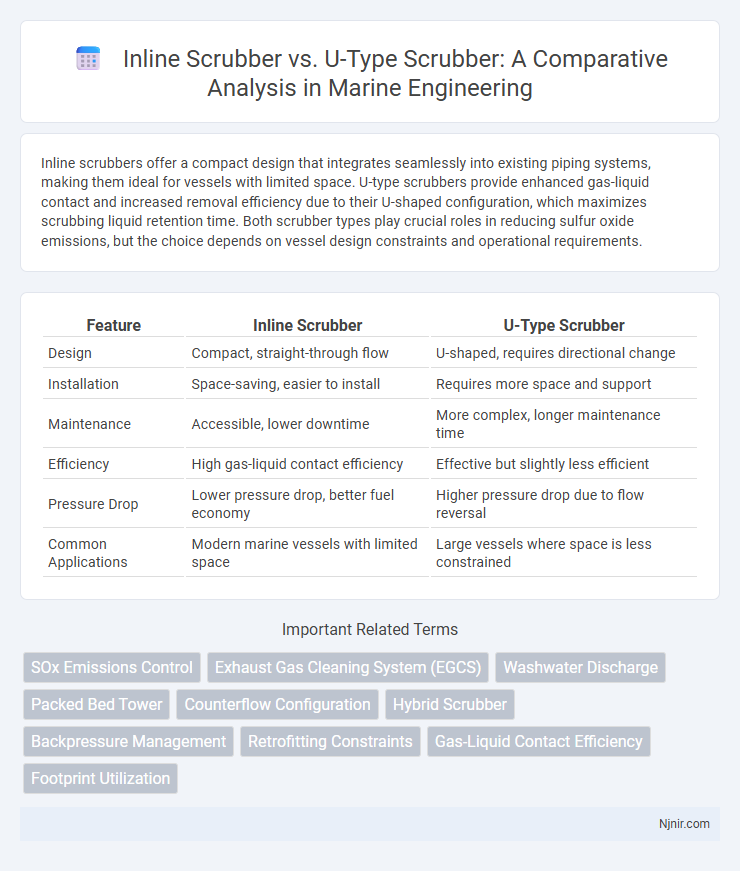

| Feature | Inline Scrubber | U-Type Scrubber |

|---|---|---|

| Design | Compact, straight-through flow | U-shaped, requires directional change |

| Installation | Space-saving, easier to install | Requires more space and support |

| Maintenance | Accessible, lower downtime | More complex, longer maintenance time |

| Efficiency | High gas-liquid contact efficiency | Effective but slightly less efficient |

| Pressure Drop | Lower pressure drop, better fuel economy | Higher pressure drop due to flow reversal |

| Common Applications | Modern marine vessels with limited space | Large vessels where space is less constrained |

Overview of Marine Scrubber Systems

Marine scrubber systems, such as Inline Scrubbers and U-Type Scrubbers, serve to reduce sulfur oxide (SOx) emissions from ship exhaust gases, ensuring compliance with International Maritime Organization (IMO) regulations. Inline Scrubbers are compact, integrated units installed directly in the exhaust line, providing efficient wet scrubbing with minimal space requirements. U-Type Scrubbers, characterized by their looped configuration, offer enhanced gas-liquid contact and are favored for larger vessels due to their higher treatment capacity and maintenance accessibility.

Principles of Inline Scrubber Operation

Inline scrubbers operate by forcing contaminated gas through a narrow, enclosed tube where liquid absorbents contact the gas stream, promoting efficient removal of pollutants through direct interaction. The design allows for continuous flow and high turbulence, enhancing mass transfer and pollutant capture without external pumps or vessels. This contrasts with U-type scrubbers, which rely on immersion and liquid pool dynamics for gas-liquid contact, typically resulting in lower turbulence and different operational efficiencies.

Understanding U-Type Scrubber Design

U-Type scrubbers feature a compact, U-shaped design that facilitates efficient gas-liquid contact by directing flue gas through a liquid-filled chamber, enhancing particulate and pollutant removal. Inline scrubbers, typically straight in configuration, are easier to install in linear piping systems but may offer less contact time compared to U-Type scrubbers. The unique geometry of U-Type scrubbers improves mass transfer efficiency and reduces pressure drop, making them ideal for applications requiring high removal efficiency in limited space.

Space and Installation Requirements

Inline scrubbers offer a compact design ideal for limited space applications, integrating directly into existing pipelines with minimal modifications. U-type scrubbers require a larger footprint due to their bent configuration, demanding more room for installation and maintenance access. Space-efficient Inline scrubbers reduce installation time and associated costs, making them suitable for tight industrial environments.

Efficiency in Sulphur Removal

Inline scrubbers achieve high efficiency in sulfur removal by directing flue gases through a compact, vertical chamber with optimized packing material, enhancing gas-liquid contact and maximizing SO2 absorption rates of up to 95%. U-type scrubbers utilize a horizontal design that allows longer retention time and better distribution of alkaline scrubbing liquid, often reaching sulfur removal efficiencies around 90-93%. The choice between the two depends on space constraints and desired removal rates, with inline scrubbers generally providing superior performance in compact installations.

Impact on Vessel Stability and Performance

Inline scrubbers integrate seamlessly into the vessel's exhaust system, maintaining consistent weight distribution and minimizing impact on stability by occupying less dedicated space. U-type scrubbers, due to their larger size and separate placement, can shift the center of gravity and potentially affect vessel stability and maneuverability. Vessel performance can slightly improve with inline scrubbers as they reduce drag and maintain hydrodynamic efficiency compared to U-type scrubbers, which may impose additional weight and space constraints.

Maintenance and Operational Costs

Inline scrubbers typically incur lower maintenance costs due to their compact design and fewer moving parts, resulting in reduced downtime and simpler servicing procedures. In contrast, U-type scrubbers often require more frequent inspections and part replacements because of their larger size and complex configurations, increasing overall operational expenses. Operational costs for inline scrubbers benefit from energy-efficient performance and streamlined installation, whereas U-type scrubbers can demand higher energy consumption and labor-intensive upkeep.

Compatibility with Different Vessel Types

Inline scrubbers offer high compatibility with various vessel types, including container ships, bulk carriers, and tankers, due to their compact design and easier retrofit capabilities. U-type scrubbers require more space and structural modifications, making them less suitable for smaller vessels or those with limited engine room space. Both scrubber types effectively reduce sulfur emissions, but the choice depends largely on vessel size, engine configuration, and available installation space.

Environmental Compliance and Regulations

Inline scrubbers and U-type scrubbers both play critical roles in environmental compliance by reducing industrial emissions and meeting stringent air quality regulations. Inline scrubbers efficiently treat exhaust gases in compact systems, optimizing space while achieving compliance with limits on sulfur oxides (SOx), nitrogen oxides (NOx), and particulate matter set by agencies such as the EPA and EU standards. U-type scrubbers, favored for their robust design and high removal efficiency, are widely used in industries with strict regulatory requirements for controlling pollutants, ensuring adherence to the Clean Air Act and other international environmental mandates.

Choosing the Right Scrubber for Your Fleet

Selecting the right scrubber for your fleet depends on factors like vessel size, operational area, and emission regulations. Inline scrubbers offer compact design and are ideal for smaller vessels with space constraints, whereas U-Type scrubbers provide higher gas-liquid contact efficiency suitable for larger ships needing robust SOx removal. Evaluating fuel sulfur content, installation costs, and maintenance requirements ensures optimal compliance and fuel cost savings.

SOx Emissions Control

Inline scrubbers effectively reduce SOx emissions by treating exhaust gases within the duct, while U-Type scrubbers offer enhanced SOx removal efficiency through increased contact time and water flow design.

Exhaust Gas Cleaning System (EGCS)

Inline scrubbers in Exhaust Gas Cleaning Systems (EGCS) offer compact installation and efficient removal of pollutants within the exhaust line, while U-Type scrubbers provide enhanced gas-liquid contact and flexibility for higher contaminant loads in marine emissions control.

Washwater Discharge

Inline scrubbers typically produce lower volumes of washwater discharge with higher contaminant concentration, whereas U-type scrubbers generate larger washwater volumes with comparatively diluted pollutants, impacting treatment and disposal processes.

Packed Bed Tower

Inline scrubbers provide compact gas-liquid contact within a streamlined design, while U-type scrubbers offer enhanced liquid distribution and pressure drop control, both optimizing pollutant removal efficiency in packed bed towers.

Counterflow Configuration

The counterflow configuration in Inline Scrubbers offers higher gas-liquid contact efficiency and reduced pressure drop compared to U-Type Scrubbers, making it ideal for compact industrial gas cleaning applications.

Hybrid Scrubber

Hybrid scrubbers combine features of Inline and U-Type scrubbers, optimizing contaminant removal efficiency while minimizing space requirements in industrial gas cleaning systems.

Backpressure Management

Inline scrubbers typically offer lower backpressure due to streamlined flow paths, whereas U-type scrubbers may generate higher backpressure because of their curved design affecting fluid dynamics.

Retrofitting Constraints

Inline scrubbers offer easier installation with minimal space requirements, while U-type scrubbers face significant retrofitting constraints due to larger footprint and complex ductwork modifications.

Gas-Liquid Contact Efficiency

Inline scrubbers provide higher gas-liquid contact efficiency than U-type scrubbers due to their enhanced turbulence and improved surface area for mass transfer.

Footprint Utilization

Inline scrubbers offer superior footprint utilization by integrating directly into existing pipelines, whereas U-type scrubbers typically require larger space due to their separate vessel design.

Inline Scrubber vs U-Type Scrubber Infographic

njnir.com

njnir.com