Rigid coupling provides a solid, immovable connection between shafts, ensuring precise alignment and torque transmission in marine engines but can cause stress and misalignment issues under vibration or thermal expansion. Flexible coupling absorbs vibrations and accommodates slight misalignments, enhancing the durability and operational smoothness of marine propulsion systems by reducing mechanical wear. Choosing between rigid and flexible coupling depends on balancing alignment accuracy against the need for vibration damping and shaft flexibility in marine engineering applications.

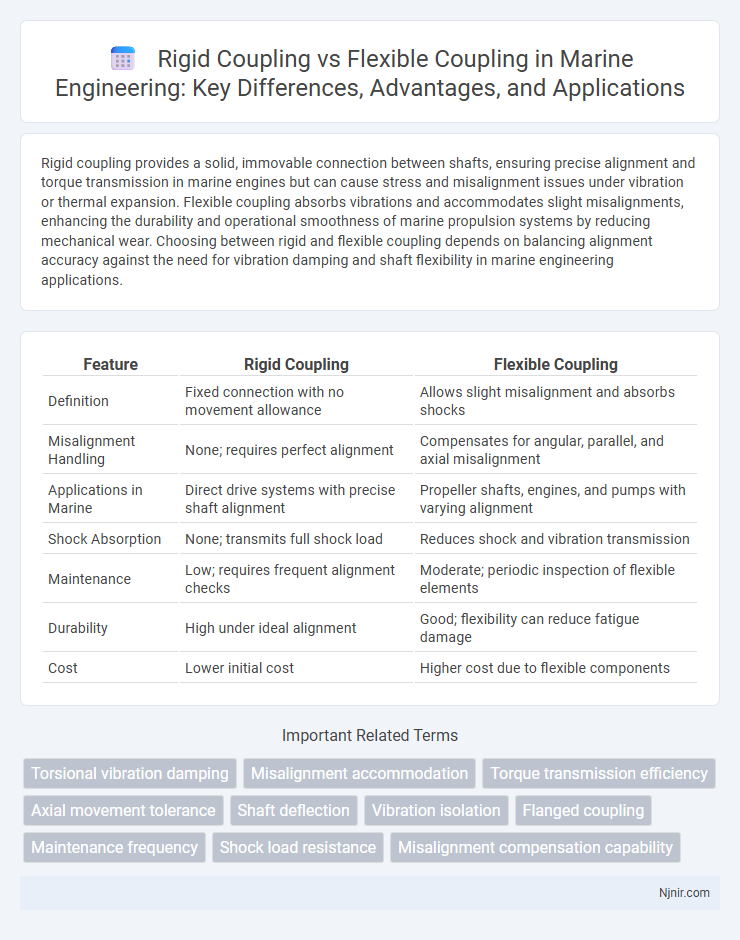

Table of Comparison

| Feature | Rigid Coupling | Flexible Coupling |

|---|---|---|

| Definition | Fixed connection with no movement allowance | Allows slight misalignment and absorbs shocks |

| Misalignment Handling | None; requires perfect alignment | Compensates for angular, parallel, and axial misalignment |

| Applications in Marine | Direct drive systems with precise shaft alignment | Propeller shafts, engines, and pumps with varying alignment |

| Shock Absorption | None; transmits full shock load | Reduces shock and vibration transmission |

| Maintenance | Low; requires frequent alignment checks | Moderate; periodic inspection of flexible elements |

| Durability | High under ideal alignment | Good; flexibility can reduce fatigue damage |

| Cost | Lower initial cost | Higher cost due to flexible components |

Introduction to Coupling in Marine Engineering

Rigid coupling in marine engineering provides a solid, inflexible connection between shafts, ensuring precise torque transmission without allowing misalignment. Flexible coupling compensates for shaft misalignment, vibration, and thermal expansion, enhancing durability and operational reliability of marine propulsion systems. Selection between these couplings depends on alignment accuracy, load conditions, and maintenance requirements in marine vessel design.

Overview of Rigid Coupling

Rigid coupling provides a solid and inflexible connection between two shafts, ensuring precise torque transmission without any relative motion or misalignment compensation. Commonly made from materials like cast iron or steel, rigid couplings are ideal for applications requiring accurate shaft alignment and high torsional rigidity. However, they are unsuitable for systems subject to shaft misalignment or thermal expansion, as any shaft displacement can cause damage or increased wear.

Overview of Flexible Coupling

Flexible couplings accommodate misalignment between connected shafts by allowing slight angular, parallel, and axial movements, reducing stress and wear on machinery components. They absorb shock loads and vibrations, enhancing the longevity and reliability of mechanical systems in applications such as pumps, compressors, and conveyors. Common types include elastomeric, gear, and diaphragm couplings, each designed to provide specific flexibility while maintaining torque transmission.

Key Differences Between Rigid and Flexible Coupling

Rigid coupling connects two shafts firmly to prevent relative motion, ideal for precise torque transmission in aligned systems, while flexible coupling accommodates misalignment and absorbs shocks to protect connected components. Rigid couplings typically exhibit higher torsional stiffness but lack vibration dampening, whereas flexible couplings reduce wear and extend machinery life by compensating for angular, parallel, and axial misalignments. Material composition and design variations in flexible couplings, such as elastomeric or metallic elements, enhance flexibility and resilience compared to the solid construction of rigid couplings.

Application Areas in Marine Systems

Rigid couplings are commonly used in marine propulsion systems where precise shaft alignment and torque transmission are critical, such as in engine-to-propeller shaft connections of cargo ships and naval vessels. Flexible couplings find extensive application in marine systems requiring vibration damping and misalignment accommodation, including auxiliary machinery like pumps, compressors, and generators on offshore platforms and cruise ships. The choice between rigid and flexible couplings directly impacts the longevity and operational efficiency of marine equipment under harsh sea conditions.

Performance Under Misalignment

Rigid couplings maintain high torque transmission efficiency but suffer significant stress and potential damage under angular, parallel, or axial misalignment. Flexible couplings accommodate various types of misalignment by absorbing shocks and vibrations, thereby reducing wear on connected machinery and extending operational lifespan. Performance under misalignment is superior in flexible couplings due to their ability to compensate for displacement without causing mechanical failure or excessive strain.

Vibration and Noise Mitigation

Rigid couplings transmit vibration and noise directly due to their solid connection, making them less effective in mitigating mechanical vibrations. Flexible couplings incorporate elastomeric elements or other damping materials that absorb and reduce vibration and noise propagation between connected shafts. Selecting flexible couplings enhances vibration isolation and noise reduction in rotating machinery, improving overall system performance and longevity.

Maintenance and Longevity

Rigid couplings require minimal maintenance due to their simple design but can cause higher wear on connected components if misaligned, potentially reducing overall system longevity. Flexible couplings absorb shock and accommodate misalignment, leading to reduced stress on shafts and bearings, which enhances durability and extends maintenance intervals. Choosing flexible couplings often results in longer equipment life and lower downtime, improving operational efficiency in industrial applications.

Cost Considerations and Installation

Rigid couplings generally have lower initial costs due to simpler design and fewer components, making them more budget-friendly for straightforward shaft connections. Installation of rigid couplings requires precise alignment and can be time-consuming, increasing labor costs if misalignment issues arise. Flexible couplings, while more expensive upfront, reduce maintenance costs by accommodating shaft misalignment and vibrations, and their installation is typically faster and less complex, lowering overall installation expenses in dynamic applications.

Selection Criteria for Marine Applications

Selection criteria for rigid coupling versus flexible coupling in marine applications depend primarily on load types, misalignment tolerance, and maintenance requirements. Rigid couplings are optimal for applications with precise shaft alignment and heavy torque transmission, offering minimal backlash but limited misalignment accommodation. Flexible couplings are preferred when dampening vibrations, compensating for axial, radial, or angular misalignments, and reducing mechanical stress to enhance system longevity in harsh marine environments.

Torsional vibration damping

Flexible couplings effectively damp torsional vibrations by absorbing misalignment and shock loads, whereas rigid couplings transmit torsional vibrations directly, causing higher stress on connected machinery.

Misalignment accommodation

Flexible couplings accommodate shaft misalignment by allowing angular, parallel, and axial movement, while rigid couplings cannot tolerate misalignment and require precise shaft alignment.

Torque transmission efficiency

Rigid couplings offer higher torque transmission efficiency by providing a solid, backlash-free connection, whereas flexible couplings accommodate misalignment but slightly reduce torque efficiency due to their elastic elements.

Axial movement tolerance

Flexible couplings tolerate significant axial movement by accommodating shaft misalignment and thermal expansion, whereas rigid couplings offer minimal axial movement tolerance due to their fixed connection design.

Shaft deflection

Rigid couplings restrict shaft deflection by maintaining precise alignment, while flexible couplings accommodate shaft deflection to reduce stress and vibration.

Vibration isolation

Flexible coupling provides superior vibration isolation compared to rigid coupling by absorbing misalignment and dampening mechanical shocks, reducing transmission of vibrations between connected shafts.

Flanged coupling

Flanged couplings, a type of rigid coupling, provide high torque transmission and precise alignment by securely bolting two shafts together with flanges, contrasting with flexible couplings that accommodate misalignment and reduce vibration through elastic elements.

Maintenance frequency

Rigid couplings require less frequent maintenance due to their solid, inflexible design, while flexible couplings need more regular inspections and maintenance to accommodate misalignment and absorb vibrations.

Shock load resistance

Flexible couplings provide superior shock load resistance by absorbing vibrations and misalignments, whereas rigid couplings transmit shocks directly to connected components, increasing potential damage.

Misalignment compensation capability

Flexible couplings excel in misalignment compensation by accommodating angular, parallel, and axial misalignments, whereas rigid couplings require precise alignment and cannot tolerate misalignment without causing system damage.

rigid coupling vs flexible coupling Infographic

njnir.com

njnir.com