Hybrid scrubbers combine the benefits of both open-loop and closed-loop systems, allowing ships to switch between seawater and freshwater for flue gas cleaning, enhancing flexibility and environmental compliance. Open-loop scrubbers rely solely on seawater to neutralize sulfur oxides, which can limit their use in areas with strict discharge regulations. Hybrid systems offer greater operational versatility and can reduce harmful emissions more effectively, supporting sustainable marine engineering practices.

Table of Comparison

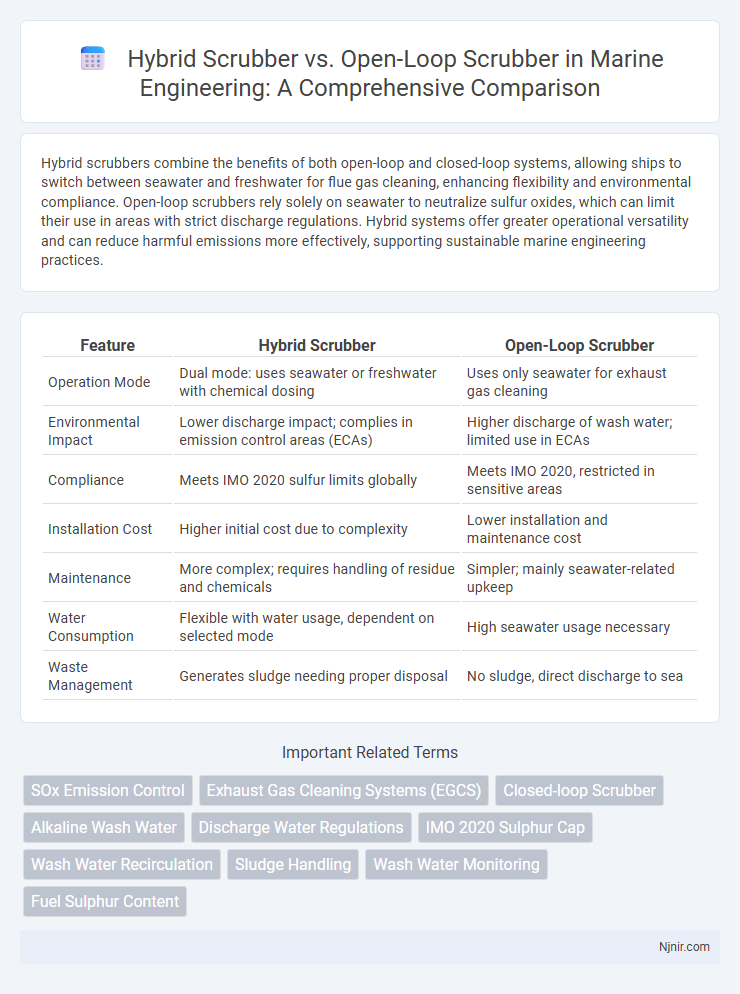

| Feature | Hybrid Scrubber | Open-Loop Scrubber |

|---|---|---|

| Operation Mode | Dual mode: uses seawater or freshwater with chemical dosing | Uses only seawater for exhaust gas cleaning |

| Environmental Impact | Lower discharge impact; complies in emission control areas (ECAs) | Higher discharge of wash water; limited use in ECAs |

| Compliance | Meets IMO 2020 sulfur limits globally | Meets IMO 2020, restricted in sensitive areas |

| Installation Cost | Higher initial cost due to complexity | Lower installation and maintenance cost |

| Maintenance | More complex; requires handling of residue and chemicals | Simpler; mainly seawater-related upkeep |

| Water Consumption | Flexible with water usage, dependent on selected mode | High seawater usage necessary |

| Waste Management | Generates sludge needing proper disposal | No sludge, direct discharge to sea |

Introduction to Marine Scrubber Technologies

Marine scrubber technologies include hybrid and open-loop systems designed to reduce sulfur oxide emissions from ship exhaust. Hybrid scrubbers combine features of both open-loop and closed-loop systems, allowing ships to switch between seawater and freshwater treatment depending on environmental regulations and water availability. Open-loop scrubbers continuously use seawater to neutralize sulfur oxides, relying on the natural alkalinity of the ocean, making them more suitable for open seas but restricted in certain coastal areas due to discharge limitations.

The Role of Scrubbers in Meeting IMO Regulations

Hybrid scrubbers combine open-loop and closed-loop systems, effectively reducing sulfur oxide (SOx) emissions to comply with IMO 2020 sulfur cap regulations while providing operational flexibility in emission control. Open-loop scrubbers use seawater to wash exhaust gases and are favored for their lower initial cost and simplicity, but their discharge restrictions in some emission control areas limit their universal applicability. Both scrubber types play a critical role in enabling ships to use high-sulfur fuels while meeting strict International Maritime Organization (IMO) standards, supporting global efforts to minimize maritime air pollution.

How Open-Loop Scrubbers Work

Open-loop scrubbers operate by channeling seawater through the exhaust gases to absorb sulfur oxides (SOx), effectively reducing emissions. The seawater's natural alkalinity neutralizes the acidic compounds before discharge back into the sea, minimizing environmental impact. This system relies on the availability of sufficient and clean seawater, making it ideal for use in open seas but less effective in confined or sensitive marine areas.

Operation Principles of Hybrid Scrubbers

Hybrid scrubbers operate by combining the features of both open-loop and closed-loop systems, allowing them to switch between seawater and freshwater with chemical additives for exhaust gas cleaning. The system uses seawater in open-loop mode under low-sulfur fuel conditions to neutralize and remove sulfur oxides (SOx) from ship emissions, while switching to closed-loop mode with recirculated freshwater and additives like caustic soda during restricted discharge zones or in areas with strict environmental regulations. This dual-mode operation optimizes compliance and efficiency by balancing environmental impact, operational costs, and regulatory requirements.

Efficiency Comparison: Open-Loop vs Hybrid Scrubbers

Hybrid scrubbers combine the water-saving benefits of closed-loop systems with the simplicity of open-loop operation, achieving higher overall efficiency in sulfur oxide (SOx) removal by optimizing water usage and reducing discharge contaminants. Open-loop scrubbers rely on seawater to neutralize exhaust gases, offering efficient SOx removal in areas with suitable water alkalinity but can be limited by discharge regulations and environmental restrictions. Hybrid scrubbers adapt to varying conditions by switching between modes, providing consistent compliance with emission standards and improved operational flexibility compared to standalone open-loop scrubbers.

Environmental Impact and Compliance

Hybrid scrubbers combine closed-loop and open-loop systems, allowing vessels to switch between seawater and freshwater with chemicals, significantly reducing sulfur oxide emissions while minimizing wastewater discharge in ECAs (Emission Control Areas). Open-loop scrubbers use seawater to neutralize sulfur oxides, effectively lowering sulfur emissions but can release washwater with contaminants back into the ocean, raising environmental concerns in sensitive areas. Compliance with IMO 2020 regulations favors hybrid scrubbers for their flexibility and reduced environmental footprint, whereas open-loop scrubbers face restrictions in certain ports due to potential marine pollution.

Installation and Maintenance Requirements

Hybrid scrubbers require more complex installation due to their ability to operate in both open-loop and closed-loop modes, involving additional components like chemical dosing and water treatment systems. Maintenance of hybrid scrubbers is intensive, necessitating regular monitoring of water quality and periodic replacement of treatment chemicals to comply with environmental regulations. Open-loop scrubbers have simpler installation processes, typically requiring only seawater intake and discharge systems, with maintenance largely focused on seawater pumps and cleaning to prevent fouling.

Cost Analysis: Initial and Lifecycle Expenses

Hybrid scrubbers involve higher initial capital investment due to their complex design combining closed-loop and open-loop systems, but offer lower lifecycle operational costs by enabling flexible use of seawater or freshwater depending on emission requirements. Open-loop scrubbers have lower upfront equipment costs and simpler installation but incur higher operational expenses from continuous seawater pumping and treatment, as well as limitations in restricted waters. Lifecycle cost efficiency favors hybrid scrubbers in regions with variable regulations, where fuel savings and reduced waste disposal contribute to overall economic benefits.

Operational Flexibility in Global Waters

Hybrid scrubbers offer superior operational flexibility in global waters by seamlessly switching between open-loop and closed-loop modes, allowing compliance with varying regional sulfur emission regulations. Open-loop scrubbers rely solely on seawater for sulfur oxide removal, limiting their effectiveness in areas with low alkalinity or stringent discharge restrictions. The ability of hybrid systems to adapt to diverse environmental conditions and legal requirements ensures optimal performance and regulatory compliance worldwide.

Future Trends in Marine Scrubber Development

Future trends in marine scrubber development emphasize increased efficiency and environmental compliance, with hybrid scrubbers gaining traction due to their ability to switch between open-loop and closed-loop modes, reducing water discharge and meeting stricter emissions regulations. Innovations in sensor technology and automation enhance real-time monitoring and system optimization, driving down operational costs and emissions more effectively than traditional open-loop scrubbers. The growing adoption of hybrid scrubbers aligns with global maritime policies targeting sulfur oxide reductions, positioning them as a versatile solution in the transition toward greener shipping practices.

SOx Emission Control

Hybrid scrubbers achieve superior SOx emission control by combining closed-loop and open-loop technologies, enabling more efficient sulfur removal and reduced environmental impact compared to solely open-loop scrubbers.

Exhaust Gas Cleaning Systems (EGCS)

Hybrid scrubbers in Exhaust Gas Cleaning Systems (EGCS) combine features of open-loop and closed-loop systems, offering flexible operation by switching between seawater and freshwater treatment to minimize environmental impact, whereas open-loop scrubbers rely solely on seawater for exhaust gas cleaning.

Closed-loop Scrubber

Closed-loop scrubbers recycle wash water internally to minimize environmental discharge, offering advantages over open-loop scrubbers by reducing seawater usage and preventing pollutant release.

Alkaline Wash Water

Hybrid scrubbers use an alkaline wash water system combining both closed-loop and open-loop processes to optimize sulfur dioxide removal and minimize effluent discharge compared to traditional open-loop scrubbers that rely solely on seawater alkalinity.

Discharge Water Regulations

Hybrid scrubbers combine closed-loop and open-loop systems to meet stricter discharge water regulations by minimizing harmful pollutants and adapting to varying water quality standards, whereas open-loop scrubbers discharge wash water directly into the sea, often facing limitations in regions with stringent environmental restrictions.

IMO 2020 Sulphur Cap

Hybrid scrubbers combine open-loop and closed-loop technologies to comply with IMO 2020 Sulphur Cap by reducing SOx emissions more flexibly and efficiently than open-loop scrubbers alone.

Wash Water Recirculation

Hybrid scrubbers optimize wash water recirculation by combining closed-loop treatment with open-loop discharge, reducing freshwater consumption and minimizing environmental impact compared to traditional open-loop scrubbers.

Sludge Handling

Hybrid scrubbers generate less sludge than open-loop scrubbers, enabling more efficient sludge handling and reducing disposal costs.

Wash Water Monitoring

Hybrid scrubbers offer more precise wash water monitoring than open-loop scrubbers by integrating real-time sensors to optimize discharge quality and comply with environmental regulations.

Fuel Sulphur Content

Hybrid scrubbers effectively reduce SOx emissions by functioning in both open-loop mode for fuels with sulfur content below 0.5% and closed-loop mode for higher sulfur fuels, providing compliance flexibility compared to solely open-loop scrubbers restricted to low-sulfur fuel usage.

Hybrid scrubber vs Open-loop scrubber Infographic

njnir.com

njnir.com