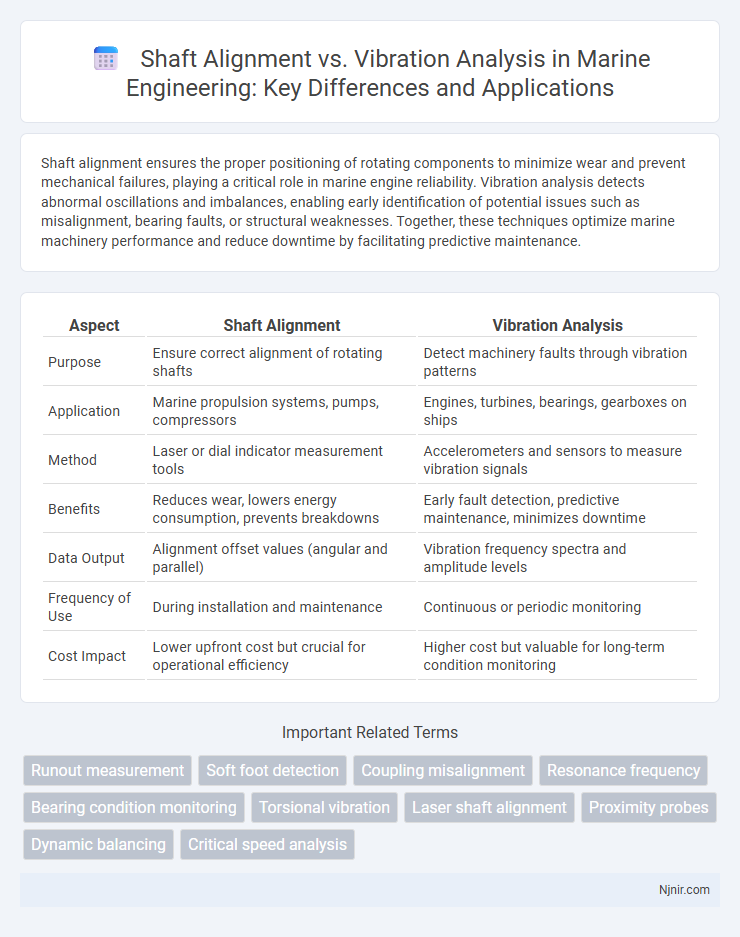

Shaft alignment ensures the proper positioning of rotating components to minimize wear and prevent mechanical failures, playing a critical role in marine engine reliability. Vibration analysis detects abnormal oscillations and imbalances, enabling early identification of potential issues such as misalignment, bearing faults, or structural weaknesses. Together, these techniques optimize marine machinery performance and reduce downtime by facilitating predictive maintenance.

Table of Comparison

| Aspect | Shaft Alignment | Vibration Analysis |

|---|---|---|

| Purpose | Ensure correct alignment of rotating shafts | Detect machinery faults through vibration patterns |

| Application | Marine propulsion systems, pumps, compressors | Engines, turbines, bearings, gearboxes on ships |

| Method | Laser or dial indicator measurement tools | Accelerometers and sensors to measure vibration signals |

| Benefits | Reduces wear, lowers energy consumption, prevents breakdowns | Early fault detection, predictive maintenance, minimizes downtime |

| Data Output | Alignment offset values (angular and parallel) | Vibration frequency spectra and amplitude levels |

| Frequency of Use | During installation and maintenance | Continuous or periodic monitoring |

| Cost Impact | Lower upfront cost but crucial for operational efficiency | Higher cost but valuable for long-term condition monitoring |

Introduction to Shaft Alignment and Vibration Analysis

Shaft alignment ensures the correct positioning of rotating machine components to minimize wear, energy loss, and equipment failure. Vibration analysis monitors machine health by detecting abnormal vibrations caused by misalignment, imbalance, or mechanical defects. Both techniques are critical for predictive maintenance, extending machinery lifespan and improving operational efficiency.

Importance in Marine Engineering Applications

Shaft alignment is critical in marine engineering to ensure the efficient transfer of power from engines to propellers, reducing wear and preventing costly equipment failures. Vibration analysis plays a key role in detecting misalignment, unbalance, and mechanical faults early, enabling predictive maintenance and minimizing downtime in marine vessels. Together, these techniques enhance operational reliability and safety of marine propulsion systems.

Fundamental Principles of Shaft Alignment

Shaft alignment involves precisely positioning the rotational axes of connected machinery components to minimize stress and wear, ensuring optimal mechanical performance. This process relies on fundamental principles such as achieving parallel and angular alignment between shafts to prevent misalignment-induced vibrations and equipment failure. Proper shaft alignment enhances the accuracy of vibration analysis by reducing alignment-related vibration sources, thereby allowing more accurate diagnostics of machine condition.

Core Concepts of Vibration Analysis

Vibration analysis focuses on measuring oscillations and frequencies within rotating machinery to detect imbalances, misalignments, and bearing faults, providing early warning signs of mechanical failures. Shaft alignment primarily ensures that connected shafts are collinear, reducing excessive vibrations and wear caused by angular or parallel misalignment. While shaft alignment corrects geometric positioning, vibration analysis offers a comprehensive diagnostic approach by analyzing vibration patterns to monitor overall machine health and prevent catastrophic breakdowns.

Key Differences Between Shaft Alignment and Vibration Analysis

Shaft alignment primarily ensures the precise positioning of rotating machine components to prevent mechanical stress and premature wear, while vibration analysis detects irregularities in machinery operation by monitoring vibration patterns. Key differences include shaft alignment's focus on mechanical positioning accuracy and correction, whereas vibration analysis emphasizes diagnosing faults such as imbalance, misalignment, or bearing defects through vibration data interpretation. Both techniques are crucial for predictive maintenance but serve distinct purposes: shaft alignment prevents misalignment-related failures, and vibration analysis identifies a broader range of operational anomalies.

Impact on Marine Propulsion System Efficiency

Shaft alignment directly influences marine propulsion system efficiency by minimizing mechanical losses and preventing premature wear, which ensures smooth power transmission from the engine to the propeller. Vibration analysis detects misalignments and mechanical imbalances early, preventing energy loss and costly system failures that degrade propulsion performance. Optimizing both shaft alignment and vibration control enhances fuel efficiency, reduces maintenance downtime, and extends the service life of marine propulsion systems.

Detection and Prevention of Machinery Failures

Shaft alignment precisely detects misalignment issues that cause excessive wear and premature bearing failure, directly preventing machinery breakdowns. Vibration analysis identifies early signs of imbalance, looseness, or bearing defects, enabling timely maintenance before catastrophic failures occur. Combining shaft alignment with vibration analysis enhances the reliability and longevity of rotating equipment by addressing both root causes and symptoms of mechanical faults.

Tools and Technologies for Shaft Alignment

Shaft alignment primarily relies on specialized laser alignment tools, dial indicators, and advanced optical machinery to ensure precise coupling and rotor positioning. Modern technologies integrate digital sensors, alignment software, and real-time feedback systems that enhance accuracy and reduce downtime during maintenance. In contrast to vibration analysis equipment, tools for shaft alignment focus on physical measurement and correction of shaft positioning rather than monitoring operational vibration patterns.

Instruments and Methods in Vibration Analysis

Vibration analysis employs instruments like accelerometers, velocity sensors, and displacement probes to measure machine vibrations, while data acquisition systems capture real-time signals for detailed diagnostics. Techniques such as Fast Fourier Transform (FFT) convert time-domain data into frequency spectra, enabling identification of specific fault frequencies linked to misalignment, imbalance, or bearing defects. Advanced methods include envelope detection and modal analysis, providing enhanced sensitivity to early-stage anomalies and complementing shaft alignment procedures through precise condition monitoring.

Best Practices for Optimal Performance and Maintenance

Shaft alignment and vibration analysis are critical for maintaining rotating machinery efficiency and preventing failures. Best practices for shaft alignment involve using laser alignment tools to achieve precise geometric positioning, minimizing shaft misalignment which reduces bearing wear and extends equipment lifespan. Vibration analysis should be performed regularly to detect early signs of imbalance, misalignment, or mechanical looseness, enabling predictive maintenance and reducing unplanned downtime for optimal operational performance.

Runout measurement

Runout measurement in shaft alignment precisely detects axial and radial deviations critical for preventing equipment imbalance, while vibration analysis identifies dynamic anomalies caused by these misalignments.

Soft foot detection

Soft foot detection in shaft alignment is crucial for preventing misalignment-induced vibrations by ensuring all machine feet make proper contact with the base, unlike vibration analysis which identifies symptoms rather than causes.

Coupling misalignment

Coupling misalignment in shaft alignment causes increased vibration amplitudes that vibration analysis can detect early to prevent equipment failure.

Resonance frequency

Resonance frequency critically impacts shaft alignment accuracy and vibration analysis by amplifying mechanical vibrations that can lead to misalignment detection errors or misdiagnosis of equipment faults.

Bearing condition monitoring

Shaft alignment precisely detects misalignment issues causing bearing wear, while vibration analysis continuously monitors bearing condition by identifying abnormal frequencies and early defect signatures.

Torsional vibration

Torsional vibration analysis provides deeper insights into shaft alignment issues by detecting angular displacement fluctuations missed by traditional vibration analysis methods.

Laser shaft alignment

Laser shaft alignment provides precise, real-time measurements to correct misalignment, reducing machinery vibration and enhancing the effectiveness of vibration analysis.

Proximity probes

Proximity probes provide precise, contactless measurements essential for accurate shaft alignment and early vibration analysis detection in rotating machinery.

Dynamic balancing

Dynamic balancing enhances shaft alignment accuracy by reducing vibration-induced imbalances that can cause premature equipment failure and operational inefficiency.

Critical speed analysis

Critical speed analysis identifies the rotational speed at which shaft alignment errors cause resonance, enabling targeted vibration analysis to prevent machinery failure.

shaft alignment vs vibration analysis Infographic

njnir.com

njnir.com