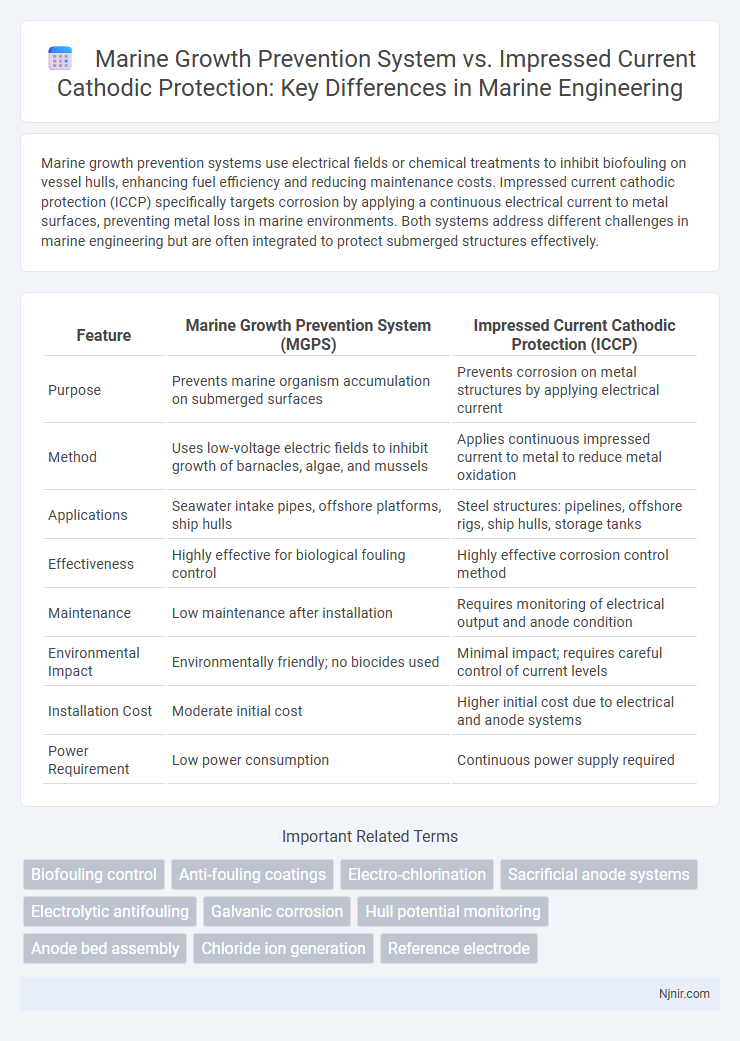

Marine growth prevention systems use electrical fields or chemical treatments to inhibit biofouling on vessel hulls, enhancing fuel efficiency and reducing maintenance costs. Impressed current cathodic protection (ICCP) specifically targets corrosion by applying a continuous electrical current to metal surfaces, preventing metal loss in marine environments. Both systems address different challenges in marine engineering but are often integrated to protect submerged structures effectively.

Table of Comparison

| Feature | Marine Growth Prevention System (MGPS) | Impressed Current Cathodic Protection (ICCP) |

|---|---|---|

| Purpose | Prevents marine organism accumulation on submerged surfaces | Prevents corrosion on metal structures by applying electrical current |

| Method | Uses low-voltage electric fields to inhibit growth of barnacles, algae, and mussels | Applies continuous impressed current to metal to reduce metal oxidation |

| Applications | Seawater intake pipes, offshore platforms, ship hulls | Steel structures: pipelines, offshore rigs, ship hulls, storage tanks |

| Effectiveness | Highly effective for biological fouling control | Highly effective corrosion control method |

| Maintenance | Low maintenance after installation | Requires monitoring of electrical output and anode condition |

| Environmental Impact | Environmentally friendly; no biocides used | Minimal impact; requires careful control of current levels |

| Installation Cost | Moderate initial cost | Higher initial cost due to electrical and anode systems |

| Power Requirement | Low power consumption | Continuous power supply required |

Overview of Marine Growth Prevention Systems

Marine Growth Prevention Systems (MGPS) utilize low-level electrical currents to inhibit biofouling on submerged structures such as ship hulls, intake pipes, and offshore platforms. Unlike Impressed Current Cathodic Protection (ICCP), which primarily prevents metal corrosion through controlled anodic current application, MGPS target the electrochemical environment to disrupt marine organism attachment and growth. These systems improve operational efficiency by reducing drag and maintenance costs associated with marine growth accumulation.

Introduction to Impressed Current Cathodic Protection

Impressed Current Cathodic Protection (ICCP) is an advanced electrochemical technique used to prevent metal corrosion in marine environments by applying a continuous protective current to submerged structures. Unlike traditional marine growth prevention systems that primarily target biofouling, ICCP specifically addresses corrosion control by converting the protected metal into a cathode, thereby reducing metal oxidation. ICCP systems are widely implemented on ship hulls, offshore platforms, and underwater pipelines to extend asset lifespan and reduce maintenance costs.

Key Functions and Purposes Compared

Marine growth prevention systems (MGPS) use low-level electrical currents to inhibit the attachment and growth of marine organisms on submerged structures, thus preserving operational efficiency and reducing maintenance costs. Impressed current cathodic protection (ICCP) systems protect metal structures from corrosion by supplying a continuous electrical current that counteracts the natural electrochemical reactions causing metal degradation. While MGPS targets biofouling control, ICCP focuses on corrosion prevention, with both systems playing crucial roles in extending the lifespan and functionality of marine infrastructure.

Mechanisms of Action: How Each System Works

Marine growth prevention systems combat biofouling by releasing low levels of biocides or copper ions that inhibit the settlement and growth of marine organisms on submerged surfaces. Impressed current cathodic protection (ICCP) works by supplying a continuous electrical current to submerged metal structures, making them cathodic and thereby preventing corrosion through electrochemical reactions. While marine growth prevention targets biological accumulation, ICCP focuses on electrochemical protection against metal deterioration.

Applications in Marine Engineering Environments

Marine growth prevention systems (MGPS) use low-level electric currents to inhibit biofouling on submerged structures, making them essential for offshore platforms, ship hulls, and seawater intake pipes. Impressed current cathodic protection (ICCP) systems protect marine steel structures from corrosion by applying a controlled external current, widely used for ship hulls, underwater pipelines, and offshore oil rigs. Both systems enhance the longevity and efficiency of marine engineering assets by preventing biological fouling and metal degradation in harsh saltwater environments.

Advantages and Limitations of MGPS

Marine Growth Prevention Systems (MGPS) offer the advantage of preventing biofouling on submerged surfaces without the use of toxic chemicals, reducing maintenance costs and environmental impact. MGPS is limited by its effectiveness primarily on metallic structures and can require continuous electrical power, which may increase operational costs in remote locations. Unlike impressed current cathodic protection, MGPS focuses on inhibiting biological growth rather than corrosion, making it unsuitable as a standalone corrosion prevention method.

Pros and Cons of ICCP Technology

Impressed Current Cathodic Protection (ICCP) technology effectively prevents marine growth by applying a controlled electric current to submerged structures, reducing corrosion and biofouling. ICCP offers long-lasting protection with minimal maintenance compared to traditional coatings, but it requires a reliable power source and periodic monitoring to avoid overprotection or underprotection, which can damage the structure. The initial installation cost is relatively high, and system complexity demands skilled operation and regular inspections to ensure optimal performance.

Installation and Maintenance Considerations

Marine growth prevention systems require precise electrode placement and waterproof cabling, with installation complexity depending on the size of the protected structure. Maintenance involves regular inspection of electrodes and electrical connections to prevent biofouling and ensure system efficiency. Impressed current cathodic protection (ICCP) installations demand careful anode placement and power supply setup, while maintenance includes monitoring current output and replacing anodes or electrical components to avoid corrosion failures.

Cost Analysis: MGPS vs ICCP

Marine Growth Prevention Systems (MGPS) typically incur higher initial installation costs compared to Impressed Current Cathodic Protection (ICCP) due to advanced filtration and chemical dosing equipment. However, MGPS offers lower operational expenses by reducing biofouling-related maintenance and energy consumption over time. ICCP systems involve substantial ongoing costs from power supply and anode replacement, making MGPS more cost-effective in environments with heavy marine growth.

Choosing the Optimal Protection System

Selecting the optimal marine growth prevention system versus impressed current cathodic protection depends on structural material, environmental conditions, and maintenance requirements. Marine growth prevention systems utilize antifouling coatings and biocides to inhibit organism attachment, ideal for reducing drag on ship hulls and submerged equipment. Impressed current cathodic protection offers electrochemical corrosion control by applying a direct current to submerged metal structures, providing long-term corrosion resistance in harsh marine environments.

Biofouling control

Impressed current cathodic protection effectively prevents metal corrosion but does not control biofouling, whereas marine growth prevention systems specifically inhibit biofouling by targeting microorganism attachment and growth on submerged surfaces.

Anti-fouling coatings

Anti-fouling coatings in marine growth prevention systems provide a chemical barrier against organism attachment, whereas impressed current cathodic protection primarily prevents metal corrosion without directly addressing biofouling.

Electro-chlorination

Electro-chlorination in marine growth prevention systems generates chlorine onsite to inhibit biofouling effectively, offering a sustainable alternative to impressed current cathodic protection by reducing corrosion without sacrificial anodes.

Sacrificial anode systems

Sacrificial anode systems prevent marine growth by providing corrosion protection through anodic dissolution, contrasting impressed current cathodic protection which uses an external power source to inhibit metal corrosion.

Electrolytic antifouling

Electrolytic antifouling systems, a type of marine growth prevention, use impressed current cathodic protection to inhibit biofouling by releasing controlled electric currents that prevent organism attachment on submerged surfaces.

Galvanic corrosion

Impressed current cathodic protection effectively minimizes galvanic corrosion by controlling electrical potential, whereas marine growth prevention systems primarily inhibit biofouling without directly addressing electrochemical corrosion mechanisms.

Hull potential monitoring

Hull potential monitoring in marine growth prevention systems uses controlled electrical currents to inhibit biological fouling, whereas impressed current cathodic protection relies on precise hull potential measurements to prevent corrosion by maintaining a protective electrochemical environment.

Anode bed assembly

The anode bed assembly in impressed current cathodic protection systems provides long-lasting, controlled corrosion prevention by distributing electrical current efficiently, whereas marine growth prevention systems rely on physical or chemical barriers that do not utilize anode bed assemblies for corrosion control.

Chloride ion generation

Marine growth prevention systems generate fewer chloride ions than impressed current cathodic protection, reducing corrosion risks and environmental impact.

Reference electrode

Reference electrodes in marine growth prevention systems provide precise potential measurements to optimize impressed current cathodic protection performance and reduce corrosion effectively.

marine growth prevention system vs impressed current cathodic protection Infographic

njnir.com

njnir.com