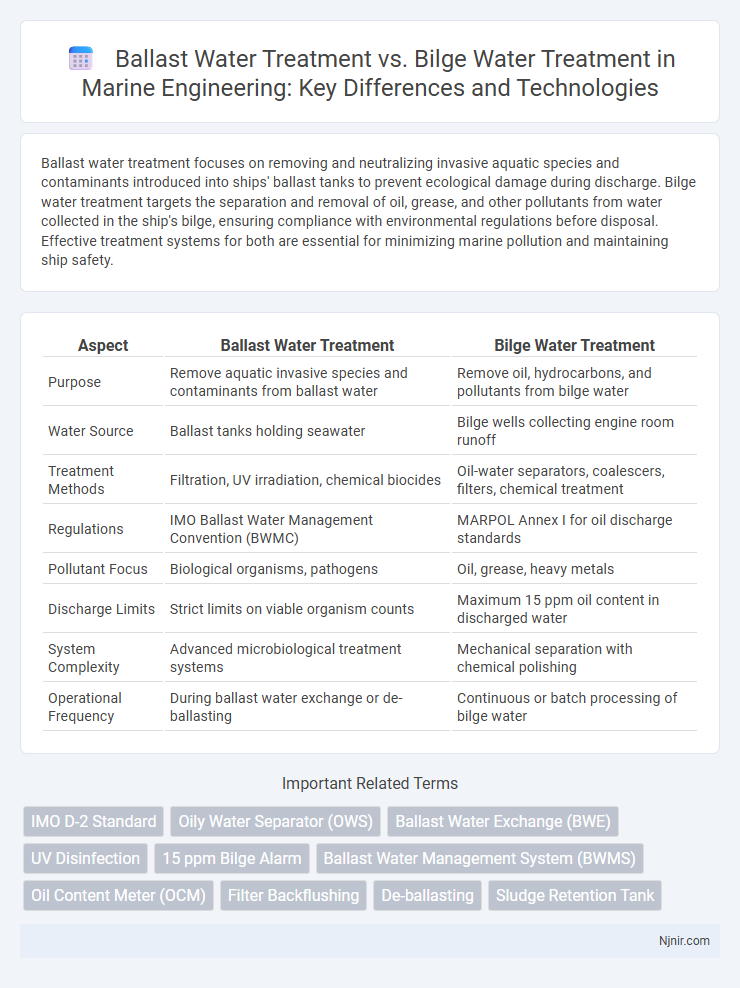

Ballast water treatment focuses on removing and neutralizing invasive aquatic species and contaminants introduced into ships' ballast tanks to prevent ecological damage during discharge. Bilge water treatment targets the separation and removal of oil, grease, and other pollutants from water collected in the ship's bilge, ensuring compliance with environmental regulations before disposal. Effective treatment systems for both are essential for minimizing marine pollution and maintaining ship safety.

Table of Comparison

| Aspect | Ballast Water Treatment | Bilge Water Treatment |

|---|---|---|

| Purpose | Remove aquatic invasive species and contaminants from ballast water | Remove oil, hydrocarbons, and pollutants from bilge water |

| Water Source | Ballast tanks holding seawater | Bilge wells collecting engine room runoff |

| Treatment Methods | Filtration, UV irradiation, chemical biocides | Oil-water separators, coalescers, filters, chemical treatment |

| Regulations | IMO Ballast Water Management Convention (BWMC) | MARPOL Annex I for oil discharge standards |

| Pollutant Focus | Biological organisms, pathogens | Oil, grease, heavy metals |

| Discharge Limits | Strict limits on viable organism counts | Maximum 15 ppm oil content in discharged water |

| System Complexity | Advanced microbiological treatment systems | Mechanical separation with chemical polishing |

| Operational Frequency | During ballast water exchange or de-ballasting | Continuous or batch processing of bilge water |

Introduction to Marine Water Management

Ballast water treatment involves the removal or neutralization of aquatic invasive species and pathogens from ships' ballast tanks to prevent ecological disruption in marine environments. Bilge water treatment targets the separation and removal of oil, chemicals, and other contaminants from water accumulated in the ship's bilge, ensuring compliance with environmental regulations and reducing marine pollution. Effective marine water management incorporates both treatments to maintain ship safety while protecting ocean ecosystems and supporting sustainable maritime operations.

Defining Ballast Water and Bilge Water

Ballast water is seawater taken into a ship's ballast tanks to maintain stability, trim, and structural integrity during voyages, often containing various marine organisms and sediments. Bilge water consists of a mixture of water, oil, grease, chemicals, and other residues that accumulate in the lowest part of a ship's hull, known as the bilge. Effective treatment of ballast water targets the removal or neutralization of invasive species and microorganisms, while bilge water treatment focuses on separating and reducing oil and contaminants to meet environmental discharge regulations.

Key Differences Between Ballast and Bilge Water

Ballast water treatment targets the removal of invasive aquatic species and contaminants from seawater taken onboard to stabilize vessels, employing filtration and biocidal processes. Bilge water treatment focuses on cleaning oily water mixtures collected from engine rooms, using oil-water separators and centrifuges to reduce hydrocarbons and pollutants before discharge. The key differences lie in their source, contamination types, and treatment technologies tailored to meet international maritime environmental regulations such as the IMO Ballast Water Management Convention and MARPOL Annex I.

Environmental Impact of Untreated Waters

Untreated ballast water releases invasive aquatic species, disrupting marine ecosystems and causing significant biodiversity loss. Untreated bilge water often contains oil, heavy metals, and chemicals, leading to toxic pollution that harms marine life and water quality. Both untreated waters contribute to ecological degradation, emphasizing the need for effective treatment technologies to protect ocean environments.

Regulatory Frameworks and Compliance Standards

Ballast water treatment is governed by the International Maritime Organization's (IMO) Ballast Water Management Convention, which mandates ships to implement approved treatment systems to prevent the spread of invasive aquatic species. Bilge water treatment must comply with MARPOL Annex I regulations, emphasizing stringent discharge standards for oil content to minimize marine pollution. Both systems require adherence to rigorous international and regional regulatory frameworks to ensure environmental protection and operational compliance.

Ballast Water Treatment Technologies

Ballast water treatment technologies primarily focus on preventing the transfer of invasive aquatic species by using filtration, ultraviolet (UV) irradiation, and chemical biocides to sanitize water before discharge. Advanced systems such as electrochlorination and deoxygenation are designed to comply with International Maritime Organization (IMO) Ballast Water Management Convention standards, ensuring environmental protection during ballast water exchange. In contrast, bilge water treatment concentrates on removing oil, grease, and contaminants using oil-water separators and chemical treatments, highlighting the distinct functional requirements between the two treatment processes.

Bilge Water Treatment Methods and Systems

Bilge water treatment methods primarily focus on separating oil, water, and solids to meet environmental discharge standards, using technologies such as oily water separators (OWS), hydrocyclones, and coalescers. Advanced bilge water treatment systems incorporate filtration and chemical dosing to enhance the removal of hydrocarbons and detergents, ensuring compliance with MARPOL Annex I regulations. Continuous monitoring and automatic shutoff mechanisms are integral to modern systems, preventing the discharge of untreated bilge water to protect marine ecosystems.

Operational Challenges in Treatment Processes

Ballast water treatment faces operational challenges such as managing high variability in water quality, including turbidity and salinity, which can affect the efficiency of filtration and disinfection systems. Bilge water treatment struggles with the presence of complex hydrocarbon pollutants and emulsified oils, requiring advanced separation and chemical treatment technologies to meet discharge standards. Both processes demand robust system maintenance and monitoring to prevent biofouling, equipment fouling, and regulatory non-compliance, complicating onboard treatment operations.

Future Trends in Marine Water Treatment Solutions

Future trends in marine water treatment emphasize advanced technologies like electrochemical oxidation and membrane bioreactors for both ballast water and bilge water treatment, aiming to meet stricter regulations such as IMO's Ballast Water Management Convention and MARPOL Annex I standards. Innovations include real-time monitoring systems and AI-driven predictive maintenance to optimize treatment efficiency and reduce environmental impact. The integration of sustainable, energy-efficient solutions highlights the industry's shift toward green shipping practices and carbon footprint reduction.

Best Practices for Effective Water Management

Ballast water treatment employs advanced filtration, UV sterilization, and chemical dosing to eliminate invasive species and pathogens, ensuring compliance with international maritime regulations such as IMO D-2 standards. Bilge water treatment prioritizes oil-water separation, adhering to MARPOL Annex I limits by utilizing coalescers, centrifuges, and oil content monitors for effective oil removal and environmental protection. Integrating real-time monitoring systems and routine maintenance enhances the efficiency of both treatments, promoting sustainable water management and minimizing ecological impact.

IMO D-2 Standard

Ballast water treatment systems must comply with the IMO D-2 Standard by reducing viable organisms to specific concentration limits, while bilge water treatment does not fall under the D-2 Standard but requires separate regulatory adherence for oil content and contaminants.

Oily Water Separator (OWS)

The Oily Water Separator (OWS) efficiently processes bilge water by removing oil and contaminants, whereas ballast water treatment systems primarily focus on eliminating invasive aquatic species and pathogens without oil separation.

Ballast Water Exchange (BWE)

Ballast water exchange (BWE) is a critical process in ballast water treatment that reduces the transfer of invasive aquatic species by replacing coastal water with open ocean water, whereas bilge water treatment primarily focuses on removing oil, grease, and chemicals from water collected in ship bilges.

UV Disinfection

UV disinfection is more effective in ballast water treatment due to higher pathogen load and regulatory standards, whereas bilge water treatment uses UV primarily to reduce oil-degrading microbial populations and chemical contaminants.

15 ppm Bilge Alarm

Ballast water treatment systems primarily target invasive species removal, while bilge water treatment focuses on oil separation and maintaining a 15 ppm bilge alarm to prevent pollution exceedances.

Ballast Water Management System (BWMS)

Ballast Water Management System (BWMS) specifically targets the treatment and management of ballast water to prevent the spread of aquatic invasive species, whereas bilge water treatment primarily focuses on removing oil, sediments, and pollutants from bilge water to comply with environmental regulations.

Oil Content Meter (OCM)

Oil Content Meters (OCMs) are crucial in ballast water treatment to accurately monitor and control oil concentrations below regulatory limits, whereas in bilge water treatment, OCMs primarily ensure compliance by detecting varying oil levels from engine room discharge.

Filter Backflushing

Ballast water treatment primarily uses filter backflushing to remove biological contaminants, while bilge water treatment employs backflushing filters to manage oil and solid residues effectively.

De-ballasting

De-ballasting in ballast water treatment involves removing and treating large volumes of seawater to prevent invasive species transfer, whereas bilge water treatment focuses on separating oil and contaminants from water collected in the ship's lower compartments.

Sludge Retention Tank

Sludge retention tanks in ballast water treatment systems specifically capture and separate contaminants from seawater to prevent environmental pollution, whereas in bilge water treatment, these tanks primarily store oily sludge separated from engine room waste before proper disposal or recycling.

Ballast water treatment vs Bilge water treatment Infographic

njnir.com

njnir.com