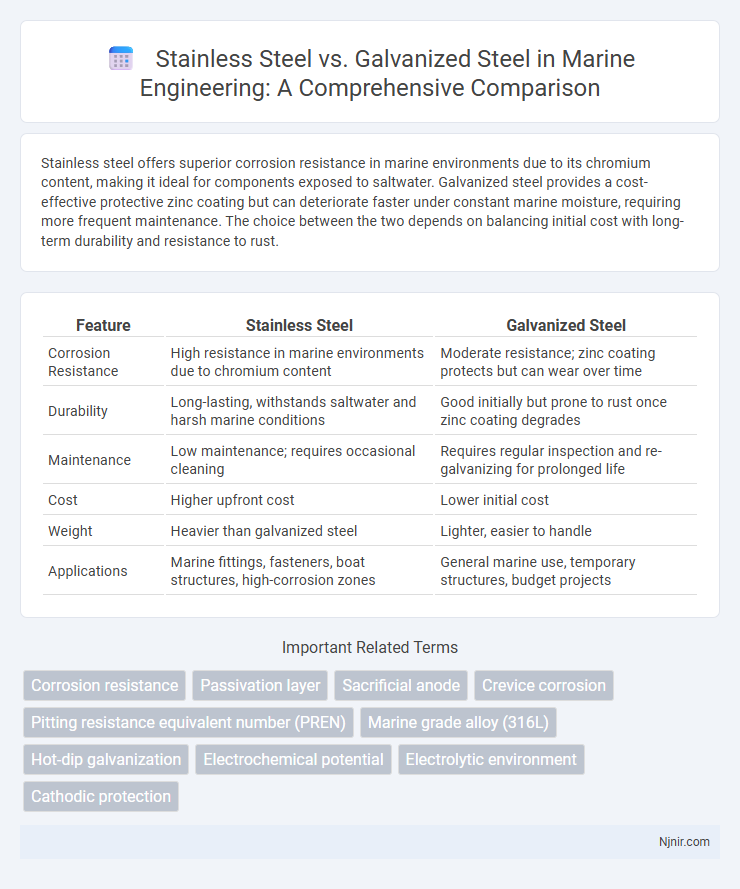

Stainless steel offers superior corrosion resistance in marine environments due to its chromium content, making it ideal for components exposed to saltwater. Galvanized steel provides a cost-effective protective zinc coating but can deteriorate faster under constant marine moisture, requiring more frequent maintenance. The choice between the two depends on balancing initial cost with long-term durability and resistance to rust.

Table of Comparison

| Feature | Stainless Steel | Galvanized Steel |

|---|---|---|

| Corrosion Resistance | High resistance in marine environments due to chromium content | Moderate resistance; zinc coating protects but can wear over time |

| Durability | Long-lasting, withstands saltwater and harsh marine conditions | Good initially but prone to rust once zinc coating degrades |

| Maintenance | Low maintenance; requires occasional cleaning | Requires regular inspection and re-galvanizing for prolonged life |

| Cost | Higher upfront cost | Lower initial cost |

| Weight | Heavier than galvanized steel | Lighter, easier to handle |

| Applications | Marine fittings, fasteners, boat structures, high-corrosion zones | General marine use, temporary structures, budget projects |

Introduction to Stainless Steel and Galvanized Steel in Marine Engineering

Stainless steel, known for its high chromium content, offers exceptional corrosion resistance and durability in harsh marine environments, making it ideal for shipbuilding and offshore structures. Galvanized steel, coated with a layer of zinc, provides cost-effective protection against rust but may require more frequent maintenance due to coating wear in saltwater exposure. Both materials are essential in marine engineering, with stainless steel favored for longevity and galvanized steel for budget-sensitive applications.

Composition and Manufacturing Processes

Stainless steel is primarily composed of iron, carbon, and a minimum of 10.5% chromium, which forms a passive layer preventing corrosion, while galvanized steel consists of carbon steel coated with a layer of zinc applied through hot-dip galvanization or electro-galvanization methods to enhance rust resistance. The chromium content in stainless steel ensures inherent corrosion resistance, whereas galvanized steel relies on the sacrificial protection of the zinc coating that corrodes before the underlying steel. Manufacturing stainless steel involves melting and alloying processes to achieve precise chemical composition, whereas galvanized steel production includes steel fabrication followed by coating in molten zinc baths or electrochemical deposition.

Corrosion Resistance in Marine Environments

Stainless steel exhibits superior corrosion resistance in marine environments due to its chromium content, which forms a passive oxide layer protecting against rust and pitting. Galvanized steel relies on a zinc coating that provides sacrificial protection but can degrade faster when exposed to saltwater and mechanical damage. For long-term durability in harsh marine conditions, stainless steel is preferred as it resists corrosion and maintains structural integrity without frequent maintenance.

Mechanical Strength and Durability

Stainless steel exhibits superior mechanical strength and corrosion resistance compared to galvanized steel, making it ideal for applications requiring long-term durability and minimal maintenance. Galvanized steel, coated with a layer of zinc, offers good protection against rust but tends to weaken over time under harsh environmental conditions or mechanical stress. Choosing stainless steel ensures enhanced toughness and longevity in structural uses where strength and durability are critical factors.

Maintenance Requirements and Longevity

Stainless steel requires minimal maintenance due to its corrosion-resistant chromium content, ensuring durability even in harsh environments. Galvanized steel relies on a zinc coating to prevent rust, which may degrade over time and necessitate periodic inspections and touch-ups. Stainless steel generally offers superior longevity, often exceeding 50 years, while galvanized steel typically lasts 20 to 30 years depending on exposure and maintenance quality.

Cost Analysis: Initial and Lifecycle Expenses

Stainless steel typically has a higher initial cost compared to galvanized steel due to its alloy composition and corrosion-resistant properties. Galvanized steel offers lower upfront expenses but may incur increased maintenance and replacement costs over its lifecycle because the zinc coating can deteriorate. Evaluating total cost of ownership involves factoring in durability, environmental exposure, and long-term performance, where stainless steel often proves more cost-effective in corrosive environments.

Applications and Suitability in Marine Projects

Stainless steel, especially grades 316 and 304, offers exceptional corrosion resistance and durability ideal for marine environments, making it suitable for boat fittings, offshore platforms, and coastal structures. Galvanized steel, coated with a protective zinc layer, provides cost-effective corrosion protection but is better suited for less harsh marine applications such as docks and piers where prolonged saltwater exposure is limited. The choice between stainless steel and galvanized steel depends on the specific marine project's exposure level, load requirements, and maintenance expectations.

Environmental Impact and Sustainability

Stainless steel offers superior corrosion resistance, resulting in longer product lifespan and reduced material waste compared to galvanized steel, which requires frequent recoating and replacement. The production of stainless steel generally involves higher energy consumption, but its recyclability rate exceeds 90%, minimizing landfill contributions and resource extraction. Galvanized steel's zinc coating can pose environmental risks during corrosion, whereas stainless steel's inert surface contributes to lower ecological toxicity and better sustainability profiles in industrial applications.

Safety Considerations in Marine Usage

Stainless steel offers superior corrosion resistance in marine environments due to its chromium content, significantly reducing risks of structural failure from rust and metal fatigue. Galvanized steel, while initially protected by a zinc coating, can degrade faster in saltwater, increasing the potential for hazardous material weakening and subsequent safety issues. Choosing stainless steel enhances long-term durability and minimizes maintenance, ensuring safer applications in harsh marine conditions.

Choosing the Right Steel for Your Marine Engineering Needs

Stainless steel offers superior corrosion resistance and durability in marine environments due to its chromium content, making it ideal for components exposed to saltwater and high humidity. Galvanized steel provides a cost-effective option with a zinc coating that protects against rust, suitable for less critical structures or applications with limited exposure to direct seawater. Selecting the right steel depends on factors like environmental conditions, maintenance requirements, and budget constraints, with stainless steel excelling in longevity and galvanized steel favored for economical short-term use.

Corrosion resistance

Stainless steel offers superior corrosion resistance compared to galvanized steel due to its chromium content that forms a passive oxide layer protecting against rust and environmental damage.

Passivation layer

The passivation layer in stainless steel, primarily composed of chromium oxide, provides superior corrosion resistance compared to the zinc coating in galvanized steel.

Sacrificial anode

Galvanized steel uses a zinc sacrificial anode to prevent corrosion, while stainless steel relies on a chromium oxide passive layer without sacrificial anodes for corrosion resistance.

Crevice corrosion

Stainless steel resists crevice corrosion due to its chromium oxide layer, while galvanized steel is more susceptible as the zinc coating can break down in crevices, accelerating corrosion.

Pitting resistance equivalent number (PREN)

Stainless steel typically exhibits a higher Pitting Resistance Equivalent Number (PREN) than galvanized steel, indicating superior resistance to localized corrosion in chloride-rich environments.

Marine grade alloy (316L)

Marine grade 316L stainless steel offers superior corrosion resistance and durability compared to galvanized steel, making it ideal for harsh marine environments and prolonged saltwater exposure.

Hot-dip galvanization

Hot-dip galvanization enhances steel corrosion resistance by coating it with a thick layer of zinc, making galvanized steel more durable than bare stainless steel in harsh outdoor environments.

Electrochemical potential

Stainless steel exhibits a higher electrochemical potential than galvanized steel, making it more resistant to corrosion in electrolytic environments.

Electrolytic environment

Stainless steel outperforms galvanized steel in electrolytic environments due to its superior corrosion resistance and resistance to electrochemical degradation.

Cathodic protection

Stainless steel resists corrosion naturally through its chromium oxide layer, while galvanized steel relies on zinc coating for cathodic protection, sacrificing the zinc sacrificially to protect the steel substrate.

Stainless Steel vs Galvanized Steel Infographic

njnir.com

njnir.com