Carbon composite propellers offer significant advantages over bronze propellers, including reduced weight and improved fuel efficiency due to lower drag and enhanced hydrodynamic performance. The corrosion resistance of carbon composites extends the lifespan of the propeller and reduces maintenance costs, especially in harsh marine environments. Furthermore, the flexibility of carbon composites allows for better absorption of shock loads, minimizing vibration and protecting the propulsion system.

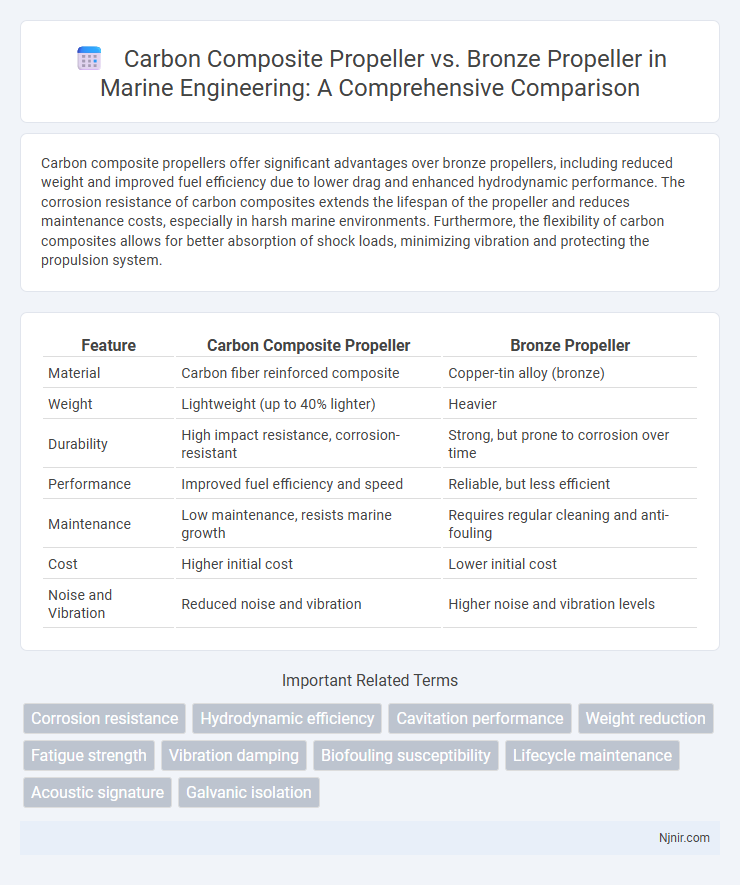

Table of Comparison

| Feature | Carbon Composite Propeller | Bronze Propeller |

|---|---|---|

| Material | Carbon fiber reinforced composite | Copper-tin alloy (bronze) |

| Weight | Lightweight (up to 40% lighter) | Heavier |

| Durability | High impact resistance, corrosion-resistant | Strong, but prone to corrosion over time |

| Performance | Improved fuel efficiency and speed | Reliable, but less efficient |

| Maintenance | Low maintenance, resists marine growth | Requires regular cleaning and anti-fouling |

| Cost | Higher initial cost | Lower initial cost |

| Noise and Vibration | Reduced noise and vibration | Higher noise and vibration levels |

Introduction to Marine Propeller Materials

Carbon composite propellers offer superior strength-to-weight ratios and corrosion resistance compared to traditional bronze propellers, enhancing vessel performance and fuel efficiency. Bronze propellers, known for their durability and excellent resistance to cavitation and marine growth, remain a reliable choice for many marine applications. Advances in composite technology allow carbon propellers to reduce noise and vibration, providing smoother operation in diverse marine environments.

Overview of Carbon Composite Propellers

Carbon composite propellers offer superior strength-to-weight ratios compared to traditional bronze propellers, resulting in improved fuel efficiency and enhanced vessel performance. These propellers exhibit excellent corrosion resistance and reduced vibration, leading to longer service life and lower maintenance costs. Advanced carbon fiber construction allows for precise blade designs that optimize thrust and reduce noise in marine applications.

Overview of Bronze Propellers

Bronze propellers are highly valued in marine applications for their durability, corrosion resistance, and ability to withstand impact and abrasion in harsh saltwater environments. These propellers offer excellent strength and are commonly used in commercial and recreational boats due to their proven reliability and cost-effectiveness. Despite being heavier than carbon composite propellers, bronze propellers provide superior resistance to cavitation and maintain optimal performance over long-term use.

Weight and Performance Differences

Carbon composite propellers weigh significantly less than bronze propellers, reducing overall vessel weight and improving fuel efficiency. The lighter carbon composite blades enhance acceleration and maneuverability due to lower rotational inertia. Bronze propellers, while heavier, offer excellent durability and resistance to impact, but the weight disadvantage can slightly reduce top speed and responsiveness.

Corrosion and Durability Comparison

Carbon composite propellers offer superior corrosion resistance compared to bronze propellers, as composites are impervious to saltwater and marine chemicals. Bronze propellers, while strong and durable, are prone to galvanic corrosion and pitting when exposed to seawater over time. Carbon composites maintain structural integrity longer in harsh marine environments, reducing maintenance needs and replacement frequency relative to bronze alternatives.

Hydrodynamic Efficiency

Carbon composite propellers offer superior hydrodynamic efficiency compared to bronze propellers due to their lighter weight and ability to maintain precise blade shapes under load, resulting in reduced drag and improved thrust. The flexibility of carbon composites allows for optimized blade geometry that adapts to varying water flow conditions, enhancing propulsion performance. Bronze propellers, while durable, typically have higher inertia and less adaptability, leading to decreased efficiency in dynamic marine environments.

Maintenance Requirements and Costs

Carbon composite propellers require less maintenance than bronze propellers due to their corrosion resistance and lightweight design, reducing the need for frequent inspections and repairs. Bronze propellers, while durable, are prone to marine corrosion and biofouling, leading to higher maintenance costs over time. The initial investment in carbon composite propellers is often higher, but the lowered upkeep expenses and extended lifespan provide better long-term cost efficiency.

Environmental Impact and Sustainability

Carbon composite propellers generate less environmental impact compared to bronze propellers due to their lightweight nature, which improves fuel efficiency and reduces greenhouse gas emissions from vessels. The manufacturing process of carbon composites typically involves lower energy consumption and enables longer lifespan, decreasing the frequency of replacements and material waste. Bronze propellers, while durable, require mining and smelting of metals, resulting in higher carbon emissions and less sustainable resource use.

Suitability for Various Marine Applications

Carbon composite propellers offer superior corrosion resistance and lightweight advantages, making them ideal for high-performance and fuel-efficient vessels operating in both saltwater and freshwater environments. Bronze propellers provide exceptional durability and impact resistance, preferred for larger commercial ships and heavy-duty marine applications where robustness is critical. The choice hinges on the specific marine application demands, balancing weight, strength, corrosion resistance, and maintenance requirements.

Future Trends in Propeller Material Technology

Carbon composite propellers exhibit superior corrosion resistance, reduced weight, and enhanced fuel efficiency compared to traditional bronze propellers, driving their adoption in modern marine propulsion systems. Advances in nano-engineered carbon fibers and resin matrices are improving strength-to-weight ratios and durability under high-stress conditions, positioning carbon composites as the forefront of propeller material innovation. Emerging trends highlight hybrid materials combining carbon composites with titanium or advanced alloys to optimize performance, sustainability, and lifecycle costs in future maritime applications.

Corrosion resistance

Carbon composite propellers offer superior corrosion resistance compared to bronze propellers, making them ideal for prolonged exposure to harsh marine environments.

Hydrodynamic efficiency

Carbon composite propellers offer superior hydrodynamic efficiency compared to bronze propellers due to their lighter weight, precise blade shaping, and reduced drag, resulting in improved fuel economy and performance.

Cavitation performance

Carbon composite propellers exhibit superior cavitation resistance compared to bronze propellers due to their lighter weight, higher strength-to-weight ratio, and enhanced vibration damping properties.

Weight reduction

Carbon composite propellers reduce weight by up to 50% compared to traditional bronze propellers, enhancing fuel efficiency and vessel performance.

Fatigue strength

Carbon composite propellers exhibit significantly higher fatigue strength than bronze propellers, enabling longer service life and increased resistance to cyclic loading in marine applications.

Vibration damping

Carbon composite propellers offer superior vibration damping compared to bronze propellers, resulting in smoother operation and reduced noise levels.

Biofouling susceptibility

Carbon composite propellers exhibit significantly lower biofouling susceptibility compared to bronze propellers due to their smoother surface texture and inherent antimicrobial properties.

Lifecycle maintenance

Carbon composite propellers offer longer lifecycle maintenance with reduced corrosion risk and less frequent repairs compared to traditional bronze propellers.

Acoustic signature

Carbon composite propellers produce a significantly lower acoustic signature than bronze propellers due to their vibration-damping properties and lighter weight.

Galvanic isolation

Carbon composite propellers provide superior galvanic isolation compared to bronze propellers, reducing corrosion risk and enhancing marine propulsion system longevity.

carbon composite propeller vs bronze propeller Infographic

njnir.com

njnir.com