Azipod propulsion systems provide enhanced maneuverability and fuel efficiency by integrating electric motors directly into the pod units, allowing 360-degree rotation for precise vessel control. Z-drive configurations, featuring a vertical and horizontal shaft arrangement, offer robustness and simplicity in design, making them suitable for vessels requiring straightforward, reliable thrust direction changes. While Azipods excel in dynamic positioning and energy savings, Z-drives remain favored for their mechanical reliability and ease of maintenance in demanding marine environments.

Table of Comparison

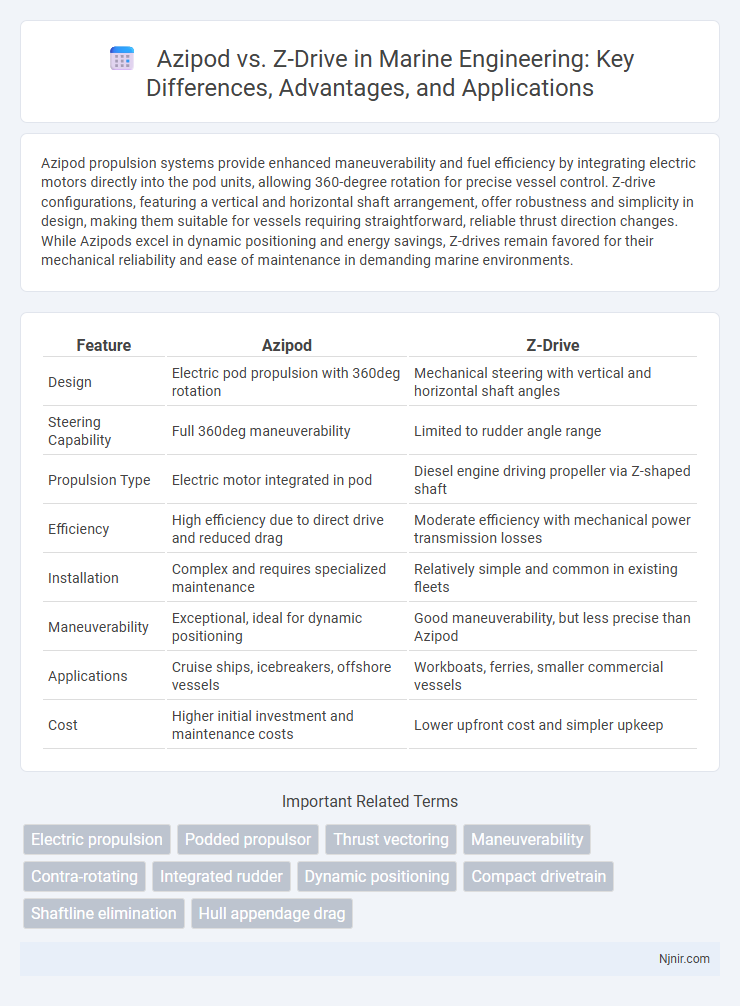

| Feature | Azipod | Z-Drive |

|---|---|---|

| Design | Electric pod propulsion with 360deg rotation | Mechanical steering with vertical and horizontal shaft angles |

| Steering Capability | Full 360deg maneuverability | Limited to rudder angle range |

| Propulsion Type | Electric motor integrated in pod | Diesel engine driving propeller via Z-shaped shaft |

| Efficiency | High efficiency due to direct drive and reduced drag | Moderate efficiency with mechanical power transmission losses |

| Installation | Complex and requires specialized maintenance | Relatively simple and common in existing fleets |

| Maneuverability | Exceptional, ideal for dynamic positioning | Good maneuverability, but less precise than Azipod |

| Applications | Cruise ships, icebreakers, offshore vessels | Workboats, ferries, smaller commercial vessels |

| Cost | Higher initial investment and maintenance costs | Lower upfront cost and simpler upkeep |

Introduction to Azipod and Z-drive Propulsion

Azipod propulsion systems feature a pod-mounted electric motor that directly drives a steerable propeller, offering enhanced maneuverability and reduced fuel consumption in marine vessels. Z-drive propulsion consists of a mechanical transmission with a vertical input shaft and horizontal output shafts connected by bevel gears, allowing 360-degree rotation for agile steering and improved vessel handling. Both technologies improve vessel control but differ fundamentally in their propulsion mechanics and installation flexibility.

Key Differences Between Azipod and Z-drive Systems

Azipod systems integrate a 360-degree rotating electric propulsion unit beneath the ship's hull, enhancing maneuverability and fuel efficiency compared to traditional Z-drive systems with fixed motors and rotating propellers. Azipods provide direct thrust vectoring, allowing precise directional control without the need for rudders, while Z-drives rely on mechanical steering via the entire propeller assembly. The compact design and higher torque of Azipods result in quieter operation and improved vessel performance, making them ideal for icebreakers, cruise ships, and dynamic positioning applications.

Historical Development of Azipod and Z-drive Technologies

Azipod technology was initially developed by ABB in the late 1980s, revolutionizing marine propulsion by integrating the electric motor within a pod that could rotate 360 degrees for superior maneuverability and fuel efficiency. Z-drive systems emerged earlier, tracing back to the 1950s and 1960s, featuring a vertical drive shaft connected to a horizontally oriented propeller, providing enhanced directional control mainly for tugboats and smaller vessels. Both technologies significantly advanced vessel handling, but Azipod's electric-driven design has become more prevalent in large ships and icebreakers due to its improved energy efficiency and reduced noise levels.

Efficiency Comparison: Azipod vs Z-drive

Azipod propulsion systems offer higher efficiency due to their 360-degree steerable pods that reduce hydrodynamic drag and improve maneuverability, resulting in fuel savings of up to 20% compared to conventional setups. Z-drive thrusters provide robust performance and quick directional changes but typically demonstrate lower overall fuel efficiency because of higher mechanical transmission losses. In applications prioritizing energy conservation and operational cost reduction, Azipod technology is often favored over Z-drive systems.

Maneuverability and Control Capabilities

Azipod propulsion systems offer superior maneuverability through 360-degree rotation of the pod, enabling precise vessel steering and dynamic positioning in challenging maritime environments. Z-drive units also provide enhanced control by rotating the propeller 360 degrees, but typically require more complex mechanical linkages and may have slower response times. The direct electric drive of Azipods minimizes mechanical losses and improves thrust vectoring, resulting in enhanced control capabilities for intricate maneuvering tasks such as docking and station keeping.

Installation and Maintenance Considerations

Azipod propulsion systems require complex hull integration due to their podded, aft-mounted design, necessitating precise alignment and specialized dry-docking for installation and maintenance. Z-drive units offer simpler installation with conventional shafting inside the hull, allowing easier access for repairs and routine servicing without extensive dry-docking. Maintenance of Azipods often involves specialized technicians and tools due to their sophisticated electric motor components, whereas Z-drives have more straightforward mechanical parts, reducing downtime and maintenance costs.

Fuel Consumption and Environmental Impact

Azipod propulsion systems typically offer better fuel efficiency compared to traditional Z-drive units due to their streamlined design and lower hydrodynamic resistance, leading to reduced greenhouse gas emissions. The electric motor in Azipods allows for precise maneuverability and optimized thrust direction, which minimizes fuel consumption during complex navigational operations. While Z-drives provide robust mechanical performance, their higher fuel usage results in greater environmental impact, making Azipods a more sustainable choice for marine vessels focused on reducing carbon footprints.

Applications in Modern Marine Vessels

Azipod propulsion systems, featuring podded electric thrusters, are widely used in cruise ships and icebreakers due to their superior maneuverability and efficiency in complex marine environments. Z-drives, with their vertically oriented input shafts and 360-degree steerable nozzles, are commonly applied in tugboats and offshore supply vessels requiring high precision in tight spaces. Both systems enhance vessel performance but are selected based on specific operational needs, such as Azipods for energy-efficient transoceanic voyages and Z-drives for robust, agile harbor maneuvering.

Cost Analysis: Initial Investment and Operational Expenses

Azipod propulsion systems typically require higher initial investment costs due to their advanced electric motor integration and hull design modifications, whereas Z-drive units tend to be more cost-effective upfront with simpler mechanical configurations. Operational expenses for Azipods can be lower over time because of enhanced fuel efficiency, reduced maintenance needs, and improved maneuverability, while Z-drives may incur higher fuel consumption and maintenance costs due to their mechanical complexity and less efficient hydrodynamics. Evaluating the total cost of ownership reveals that despite Azipods' greater initial outlay, their long-term operational savings often justify the investment for vessels prioritizing efficiency and performance.

Future Trends in Marine Propulsion Technologies

Future trends in marine propulsion emphasize Azipod systems for their superior maneuverability and fuel efficiency compared to traditional Z-drive units. Advances in Azipod technology highlight integrated electric propulsion and enhanced hydrodynamic designs aimed at reducing emissions and operational costs. The shift toward hybrid and fully electric powertrains further positions Azipods as a critical component in sustainable and eco-friendly marine vessel architectures.

Electric propulsion

Azipod electric propulsion systems offer integrated podded thrusters with 360-degree rotation for enhanced maneuverability and efficiency, while Z-drive systems utilize a vertical drive shaft connected to horizontal propellers, providing robustness and simpler maintenance.

Podded propulsor

Azipod podded propulsors offer 360-degree rotation and higher maneuverability compared to Z-drive systems, enhancing vessel efficiency and control.

Thrust vectoring

Azipods provide 360-degree thrust vectoring through their pod-mounted electric motors, enabling superior maneuverability compared to Z-drives, which rely on traditional shaft-driven, steerable propellers with more limited thrust direction control.

Maneuverability

Azipods provide superior maneuverability with 360-degree rotation enabling precise vessel control compared to Z-drives which offer less flexible directional thrust.

Contra-rotating

Contra-rotating Azipod systems enhance maneuverability and propulsion efficiency by utilizing dual counter-rotating propellers integrated within the pod, whereas Z-drive configurations typically feature a single propeller with a steering nozzle, limiting their contra-rotating capabilities.

Integrated rudder

Azipod propulsion integrates the electric motor within the pod connected directly to a steered propeller, providing precise maneuverability and enhanced efficiency compared to the externally mounted, shaft-driven rudder system of Z-drive units.

Dynamic positioning

Azipod propulsion systems offer superior Dynamic Positioning accuracy and maneuverability compared to Z-drive systems due to their 360-degree rotation and integrated electric motor design.

Compact drivetrain

Azipod offers a compact drivetrain with integrated electric propulsion and steering units ideal for space-saving and enhanced maneuverability compared to the bulkier Z-drive system.

Shaftline elimination

Azipod propulsion eliminates the traditional shaftline by integrating the electric motor directly into the pod, enhancing maneuverability and efficiency compared to Z-drive systems that retain a shaftline.

Hull appendage drag

Azipods generate lower hull appendage drag compared to Z-drives due to their external pod design and streamlined integration with the hull, improving vessel hydrodynamics and fuel efficiency.

Azipod vs Z-drive Infographic

njnir.com

njnir.com