Selective Catalytic Reduction (SCR) systems reduce nitrogen oxides (NOx) emissions by injecting a urea-based reagent into the exhaust stream, converting harmful gases into harmless nitrogen and water vapor with high efficiency. Exhaust Gas Recirculation (EGR) systems lower NOx emissions by recirculating a portion of the engine's exhaust gas back into the combustion chamber, reducing oxygen availability and combustion temperatures. SCR offers superior NOx reduction and fuel economy benefits, while EGR provides a simpler, integrated approach with lower initial costs but potentially higher maintenance requirements.

Table of Comparison

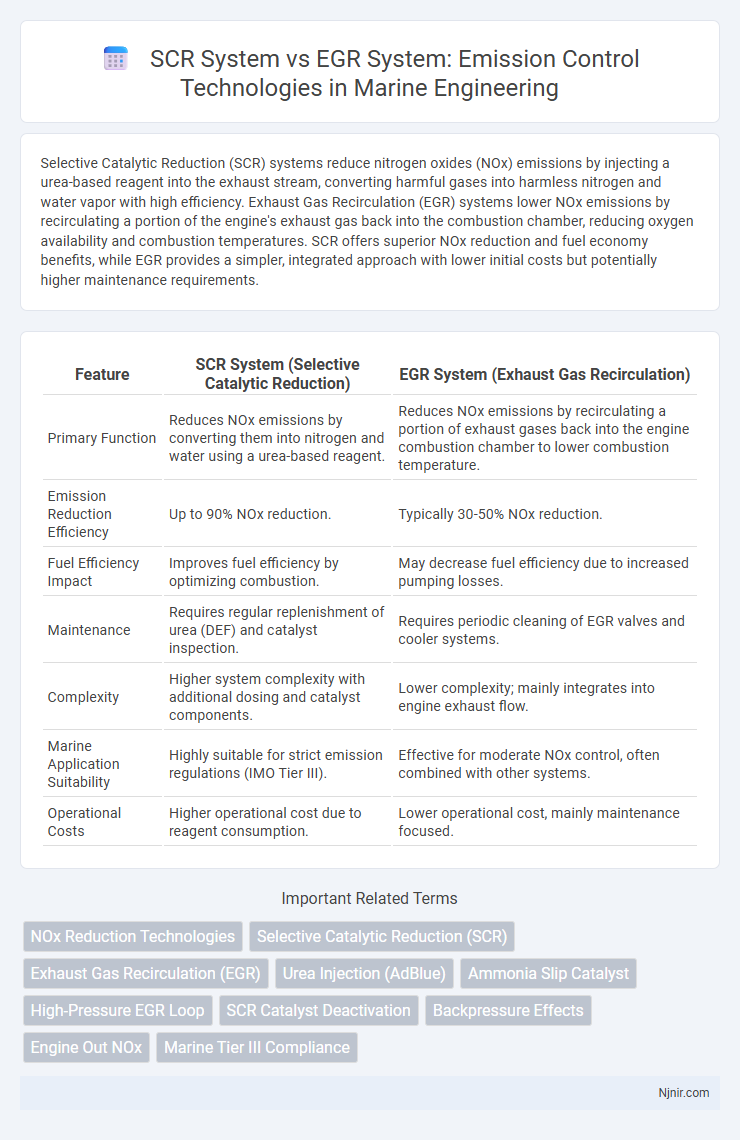

| Feature | SCR System (Selective Catalytic Reduction) | EGR System (Exhaust Gas Recirculation) |

|---|---|---|

| Primary Function | Reduces NOx emissions by converting them into nitrogen and water using a urea-based reagent. | Reduces NOx emissions by recirculating a portion of exhaust gases back into the engine combustion chamber to lower combustion temperature. |

| Emission Reduction Efficiency | Up to 90% NOx reduction. | Typically 30-50% NOx reduction. |

| Fuel Efficiency Impact | Improves fuel efficiency by optimizing combustion. | May decrease fuel efficiency due to increased pumping losses. |

| Maintenance | Requires regular replenishment of urea (DEF) and catalyst inspection. | Requires periodic cleaning of EGR valves and cooler systems. |

| Complexity | Higher system complexity with additional dosing and catalyst components. | Lower complexity; mainly integrates into engine exhaust flow. |

| Marine Application Suitability | Highly suitable for strict emission regulations (IMO Tier III). | Effective for moderate NOx control, often combined with other systems. |

| Operational Costs | Higher operational cost due to reagent consumption. | Lower operational cost, mainly maintenance focused. |

Introduction to Marine Emission Control Technologies

Selective Catalytic Reduction (SCR) systems reduce nitrogen oxide (NOx) emissions in marine engines by injecting urea-based reductants into the exhaust stream, converting NOx into harmless nitrogen and water, achieving up to 90% NOx reduction. Exhaust Gas Recirculation (EGR) systems lower NOx emissions by recirculating a portion of exhaust gases back into the engine combustion chamber, reducing combustion temperatures and oxygen availability. Both SCR and EGR technologies are essential in meeting IMO Tier III emission standards, with SCR preferred for high-efficiency NOx removal and EGR minimizing fuel penalties and system complexity.

Overview of Selective Catalytic Reduction (SCR) Systems

Selective Catalytic Reduction (SCR) systems reduce nitrogen oxide (NOx) emissions from diesel engines by injecting a urea-based reductant into the exhaust stream, converting NOx into harmless nitrogen and water through a catalytic reaction. SCR technology offers higher NOx reduction efficiency, often exceeding 90%, compared to Exhaust Gas Recirculation (EGR), which recirculates a portion of exhaust gases to lower combustion temperatures and reduce NOx formation. SCR systems require precise control of reductant dosing and catalyst temperature to optimize performance and meet stringent emission regulations such as Euro 6 and EPA Tier 4 standards.

Overview of Exhaust Gas Recirculation (EGR) Systems

Exhaust Gas Recirculation (EGR) systems reduce nitrogen oxide (NOx) emissions by recirculating a portion of exhaust gases back into the engine cylinders, lowering combustion temperatures. EGR technology helps improve fuel efficiency and decreases the formation of harmful pollutants by diluting the intake air with inert gases. Unlike Selective Catalytic Reduction (SCR) systems that use urea-based fluids for NOx conversion, EGR relies on internal engine modifications, making it a cost-effective emission control method for diesel and gasoline engines.

Working Principles: SCR vs EGR in Marine Engines

Selective Catalytic Reduction (SCR) systems reduce nitrogen oxides (NOx) emissions in marine engines by injecting a urea-based solution into the exhaust stream, where it reacts with NOx over a catalyst, converting harmful gases into nitrogen and water vapor. Exhaust Gas Recirculation (EGR) systems lower NOx formation by recirculating a portion of exhaust gases back into the engine cylinders, reducing combustion temperatures and oxygen levels, which in turn decreases NOx generation at the source. While SCR treats emissions post-combustion, EGR modifies combustion conditions internally, making SCR typically more effective for stringent marine emission regulations.

Emission Reduction Effectiveness: NOx and Beyond

SCR (Selective Catalytic Reduction) systems reduce NOx emissions by up to 90% through injecting urea-based DEF (Diesel Exhaust Fluid) into exhaust gases, converting nitrogen oxides into harmless nitrogen and water. EGR (Exhaust Gas Recirculation) systems lower NOx formation by recirculating a portion of exhaust gases back into the combustion chamber, reducing peak combustion temperatures, but typically achieve lower NOx reduction compared to SCR. Beyond NOx, SCR systems also indirectly decrease particulate matter and improve overall combustion efficiency, while EGR can increase particulate emissions due to lower combustion temperatures.

Installation and Integration Challenges

SCR systems require complex integration of a urea injection system, additional sensors, and a dedicated catalytic converter, making installation more spatially demanding and costly compared to EGR systems. EGR systems, while simpler to install as they recirculate exhaust gases within the engine, face challenges in controlling combustion temperatures and preventing soot buildup that can affect performance and emissions. Both systems necessitate careful calibration with the engine control unit (ECU) to optimize emission reduction and maintain engine efficiency under varying operating conditions.

Operation and Maintenance Requirements

SCR (Selective Catalytic Reduction) systems reduce nitrogen oxides (NOx) emissions by injecting urea-based DEF (Diesel Exhaust Fluid) into the exhaust stream, requiring regular DEF refills and periodic catalyst replacement to maintain optimal function. EGR (Exhaust Gas Recirculation) systems lower NOx by recirculating a portion of exhaust gases back into the engine intake, which demands frequent cleaning or replacement of EGR valves and cooler components to prevent clogging and maintain engine efficiency. SCR systems typically involve higher maintenance costs due to DEF management and catalyst care, while EGR systems often face increased maintenance frequency because of soot buildup and mechanical wear.

Economic Impact: Cost Comparison

Selective Catalytic Reduction (SCR) systems generally involve higher upfront costs due to the need for urea-based diesel exhaust fluid and complex catalyst components, but they offer superior nitrogen oxide (NOx) reduction efficiency that can lead to long-term fuel savings and compliance with stringent emission regulations. Exhaust Gas Recirculation (EGR) systems are typically less expensive to install and maintain, relying on rerouting exhaust gases to reduce NOx emissions, but may result in increased engine wear and reduced fuel efficiency, potentially increasing operational costs over time. The economic impact depends on factors such as fuel prices, maintenance intervals, and regulatory penalties, with SCR systems often proving cost-effective for heavy-duty applications requiring higher emission standards.

Environmental Compliance and Regulatory Drivers

Selective Catalytic Reduction (SCR) systems offer superior nitrogen oxide (NOx) reduction compared to Exhaust Gas Recirculation (EGR) systems, enabling vehicles to meet stringent global emission standards such as Euro 6 and EPA Tier 4. SCR technology uses a urea-based additive to convert NOx into nitrogen and water, ensuring compliance with increasingly tight regulatory drivers focused on minimizing air pollution and improving public health. EGR systems primarily lower combustion temperatures to reduce NOx but often struggle to meet the latest environmental compliance requirements alone, making SCR essential for achieving lower emission limits.

Future Trends and Innovations in Marine Emission Control

Selective Catalytic Reduction (SCR) systems are advancing with enhanced catalyst durability and real-time monitoring to improve nitrogen oxide (NOx) reduction efficiency in marine engines, while Exhaust Gas Recirculation (EGR) systems are evolving towards integrated thermal management for better fuel economy and particulate matter control. Future trends emphasize hybrid solutions combining SCR and EGR to meet stringent IMO Tier III regulations and achieve lower emissions with optimized operational costs. Innovations in digitalization and AI-driven analytics enable predictive maintenance and adaptive emission control strategies, enhancing performance under varying marine operating conditions.

NOx Reduction Technologies

Selective Catalytic Reduction (SCR) systems reduce NOx emissions by injecting ammonia into exhaust gases to convert NOx into nitrogen and water, offering higher efficiency than Exhaust Gas Recirculation (EGR) systems which lower combustion temperatures by recirculating a portion of exhaust gases back into the engine.

Selective Catalytic Reduction (SCR)

Selective Catalytic Reduction (SCR) systems reduce NOx emissions by injecting reductants like urea into exhaust gases, achieving higher efficiency and lower ammonia slip compared to Exhaust Gas Recirculation (EGR) systems, which recirculate a portion of exhaust gases to lower combustion temperatures and reduce NOx formation.

Exhaust Gas Recirculation (EGR)

Exhaust Gas Recirculation (EGR) reduces NOx emissions by recirculating a portion of exhaust gases back into the engine intake, lowering combustion temperatures compared to Selective Catalytic Reduction (SCR) systems that inject urea-based fluids to chemically convert NOx into nitrogen and water.

Urea Injection (AdBlue)

SCR systems use urea injection (AdBlue) to convert NOx emissions into nitrogen and water, offering higher NOx reduction efficiency compared to EGR systems that recirculate exhaust gases to lower combustion temperature.

Ammonia Slip Catalyst

SCR systems reduce NOx emissions by converting them into nitrogen and water using urea, while EGR systems recirculate exhaust gases to lower combustion temperatures; Ammonia Slip Catalyst is essential in SCR setups to mitigate ammonia slip and prevent harmful emissions.

High-Pressure EGR Loop

The High-Pressure EGR loop recirculates exhaust gases before the turbocharger to reduce NOx emissions by lowering combustion temperatures, whereas SCR systems inject urea-based solutions downstream to convert NOx into nitrogen and water.

SCR Catalyst Deactivation

SCR catalyst deactivation, caused by sulfur poisoning, thermal aging, and ash accumulation, significantly reduces the Selective Catalytic Reduction system's NOx removal efficiency compared to the EGR system's performance.

Backpressure Effects

SCR systems reduce backpressure more effectively than EGR systems by selectively injecting ammonia to convert NOx, while EGR systems increase backpressure due to recirculated exhaust gases, negatively impacting engine performance.

Engine Out NOx

SCR system reduces Engine Out NOx emissions by converting them into nitrogen and water through selective catalytic reduction, whereas EGR system lowers Engine Out NOx by recirculating a portion of exhaust gases back into the combustion chamber to reduce combustion temperature.

Marine Tier III Compliance

SCR systems achieve Marine Tier III compliance by reducing NOx emissions through selective catalytic reduction, while EGR systems lower NOx by recirculating exhaust gases but often face limitations in meeting the strict Tier III emission standards.

SCR system vs EGR system (emission control) Infographic

njnir.com

njnir.com