Seawater cooling in marine engineering offers the advantage of abundant source water, making it ideal for large vessels operating in ocean environments, but it requires corrosion-resistant materials due to the saline content. Freshwater cooling systems, while reducing the risk of corrosion and marine fouling, demand closed-loop configurations with heat exchangers to prevent contamination and rely on onboard water treatment to maintain system efficiency. Both cooling methods impact engine performance and longevity, necessitating careful selection based on vessel type, operational environment, and maintenance capabilities.

Table of Comparison

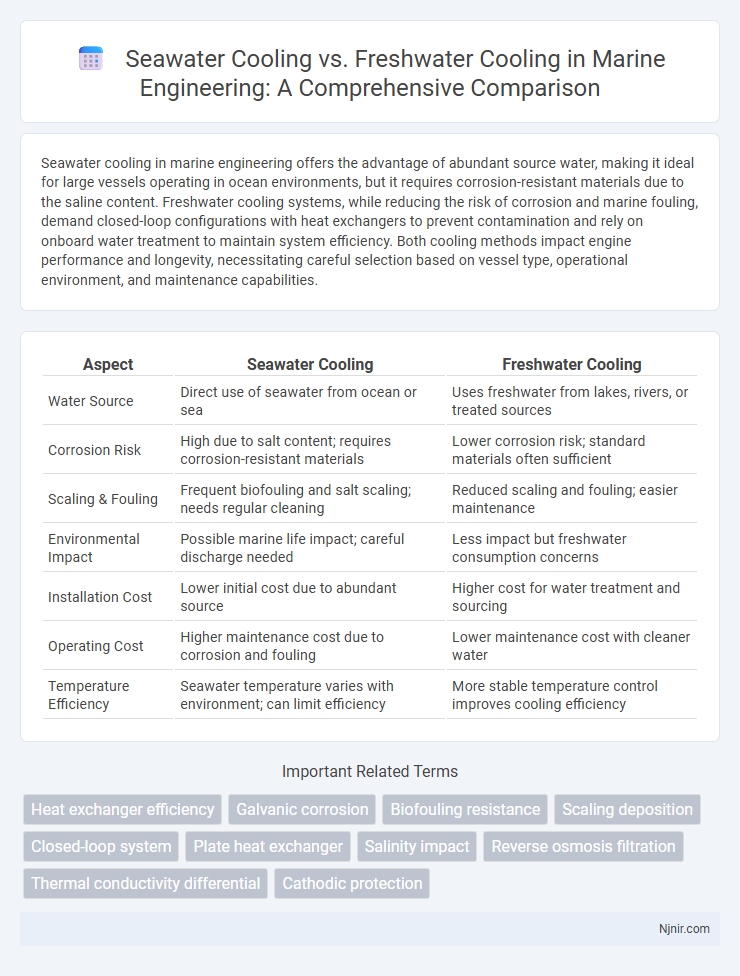

| Aspect | Seawater Cooling | Freshwater Cooling |

|---|---|---|

| Water Source | Direct use of seawater from ocean or sea | Uses freshwater from lakes, rivers, or treated sources |

| Corrosion Risk | High due to salt content; requires corrosion-resistant materials | Lower corrosion risk; standard materials often sufficient |

| Scaling & Fouling | Frequent biofouling and salt scaling; needs regular cleaning | Reduced scaling and fouling; easier maintenance |

| Environmental Impact | Possible marine life impact; careful discharge needed | Less impact but freshwater consumption concerns |

| Installation Cost | Lower initial cost due to abundant source | Higher cost for water treatment and sourcing |

| Operating Cost | Higher maintenance cost due to corrosion and fouling | Lower maintenance cost with cleaner water |

| Temperature Efficiency | Seawater temperature varies with environment; can limit efficiency | More stable temperature control improves cooling efficiency |

Introduction to Marine Cooling Systems

Marine cooling systems utilize seawater or freshwater to regulate engine and onboard equipment temperatures, critical for maintaining operational efficiency and preventing overheating. Seawater cooling exploits the abundant, naturally cool ocean water, offering cost-effective heat dissipation but requires corrosion-resistant materials due to salt content. Freshwater cooling systems use treated water circulated through heat exchangers, reducing corrosion risks and enabling better temperature control, albeit with higher maintenance and initial setup costs.

Fundamentals of Seawater Cooling

Seawater cooling utilizes the natural abundance of ocean water to absorb and dissipate heat from industrial processes or power plants, leveraging its high thermal conductivity and heat capacity. Unlike freshwater cooling, seawater's higher salinity and mineral content require corrosion-resistant materials and advanced filtration systems to prevent biofouling and scaling. The fundamental advantage lies in seawater's vast availability, enabling efficient thermal regulation without depleting freshwater resources, especially critical in coastal power generation and desalination plants.

Fundamentals of Freshwater Cooling

Freshwater cooling relies on the use of low-salinity water to absorb and dissipate heat in industrial and power generation systems, offering higher corrosion resistance and easier maintenance compared to seawater cooling. The fundamental principle involves heat exchange through evaporative cooling towers or closed-loop systems, where freshwater circulates to transfer thermal energy away from critical components. Key advantages include reduced biofouling, lower mineral scaling, and compatibility with a wider range of materials, resulting in improved system efficiency and longevity.

Comparative Efficiency: Seawater vs Freshwater

Seawater cooling systems offer higher thermal conductivity and greater heat capacity compared to freshwater, enabling more efficient heat dissipation in marine and coastal industrial applications. However, seawater's high salinity accelerates corrosion and biofouling, leading to increased maintenance and potential efficiency loss over time. Freshwater cooling provides a more controlled environment with lower corrosion risks, often resulting in better long-term operational stability despite a slightly lower heat transfer efficiency.

Corrosion and Fouling Risks

Seawater cooling systems face higher corrosion risks due to the presence of chloride ions, which accelerate metal degradation and require corrosion-resistant materials such as titanium or specialized coatings. Fouling in seawater cooling is more severe, driven by marine organisms like barnacles and algae, necessitating frequent cleaning and biocide treatments to maintain efficiency. Freshwater cooling typically experiences lower corrosion rates and fouling risks because of reduced salinity and fewer suspended solids, leading to longer equipment lifespan and less maintenance.

Maintenance Requirements and Lifespan

Seawater cooling systems require more frequent maintenance due to corrosion and biofouling caused by salt and marine organisms, leading to regular cleaning and replacement of components. Freshwater cooling systems experience less corrosion, resulting in lower maintenance demands and longer lifespan of heat exchangers and piping. Proper treatment and filtration in both systems can extend equipment life, but seawater systems generally have a shorter operational lifespan compared to freshwater setups.

Environmental Impact and Regulations

Seawater cooling systems reduce freshwater consumption, lessening strain on terrestrial water sources, but can cause thermal pollution and marine ecosystem disturbances if discharged untreated. Freshwater cooling typically involves higher freshwater withdrawals, potentially impacting local water availability and aquatic habitats, with stricter regulations governing water usage and discharge quality. Environmental compliance for seawater cooling emphasizes marine life protection and thermal discharge limits, while freshwater systems must adhere to water conservation mandates and pollutant thresholds to mitigate ecological harm.

Installation Costs and Operational Expenses

Seawater cooling systems typically incur higher installation costs due to the need for corrosion-resistant materials and advanced filtration equipment to handle saltwater's abrasive properties. Operational expenses are increased by maintenance requirements to prevent biofouling and corrosion, leading to more frequent component replacements and higher energy consumption for pumping. In contrast, freshwater cooling systems generally have lower initial installation costs and reduced maintenance expenses, but they may require additional treatment to prevent scaling and biological growth.

Suitability for Different Vessel Types

Seawater cooling systems are highly suitable for vessels operating in marine environments, such as cargo ships and fishing boats, due to their abundant and constant supply of seawater facilitating efficient heat exchange. Freshwater cooling is preferred for inland vessels, luxury yachts, and naval ships where corrosion control and component longevity are critical, as freshwater systems reduce salt-induced wear and require less maintenance. Selecting between seawater and freshwater cooling depends on vessel type, operational environment, and maintenance capabilities, ensuring optimal engine performance and durability.

Future Trends in Marine Cooling Technology

Seawater cooling systems are gaining traction due to their abundant availability and lower environmental impact compared to freshwater cooling, especially in coastal and offshore marine applications. Future trends emphasize advanced corrosion-resistant materials and biofouling mitigation techniques to enhance the efficiency and lifespan of seawater-cooled heat exchangers. Integration of smart monitoring systems and energy recovery technologies is projected to optimize thermal management while reducing operational costs in marine cooling technology.

Heat exchanger efficiency

Seawater cooling typically reduces heat exchanger efficiency due to higher salt content causing fouling and corrosion, whereas freshwater cooling offers superior efficiency through lower fouling rates and better thermal conductivity.

Galvanic corrosion

Seawater cooling accelerates galvanic corrosion due to its high salinity and conductivity, whereas freshwater cooling significantly reduces galvanic corrosion risks by offering lower ionic content and conductivity.

Biofouling resistance

Seawater cooling systems exhibit higher biofouling resistance due to natural salinity and marine organism deterrents compared to freshwater cooling systems which require frequent chemical treatments to control biological growth.

Scaling deposition

Seawater cooling systems experience higher scaling deposition due to elevated mineral content and biofouling risks compared to freshwater cooling systems, which have lower scaling tendencies and easier maintenance.

Closed-loop system

Closed-loop seawater cooling systems offer enhanced corrosion resistance and reduced freshwater consumption compared to traditional closed-loop freshwater cooling systems in industrial applications.

Plate heat exchanger

Plate heat exchangers in seawater cooling systems offer enhanced corrosion resistance and biofouling prevention compared to freshwater cooling, making them ideal for marine and coastal applications.

Salinity impact

Seawater cooling systems face increased corrosion and biofouling challenges due to high salinity levels, whereas freshwater cooling systems experience fewer salinity-related issues, resulting in lower maintenance costs and enhanced equipment lifespan.

Reverse osmosis filtration

Seawater cooling in reverse osmosis filtration requires specialized corrosion-resistant materials and advanced pre-treatment to prevent membrane fouling, while freshwater cooling offers lower salinity levels that reduce osmotic pressure and improve membrane performance.

Thermal conductivity differential

Seawater cooling outperforms freshwater cooling due to seawater's higher thermal conductivity, enhancing heat transfer efficiency in industrial applications.

Cathodic protection

Seawater cooling systems require more robust cathodic protection due to higher corrosion rates caused by salt content compared to freshwater cooling systems.

Seawater cooling vs Freshwater cooling Infographic

njnir.com

njnir.com