Integrated bridge systems (IBS) streamline navigation and control by centralizing multiple functions such as radar, autopilot, and communication into a single interface, enhancing operational efficiency and safety. Conventional bridges rely on separate, standalone instruments that can lead to increased workload and slower decision-making during critical situations. The seamless data sharing and automation capabilities of IBS reduce human error and improve situational awareness compared to traditional bridge setups.

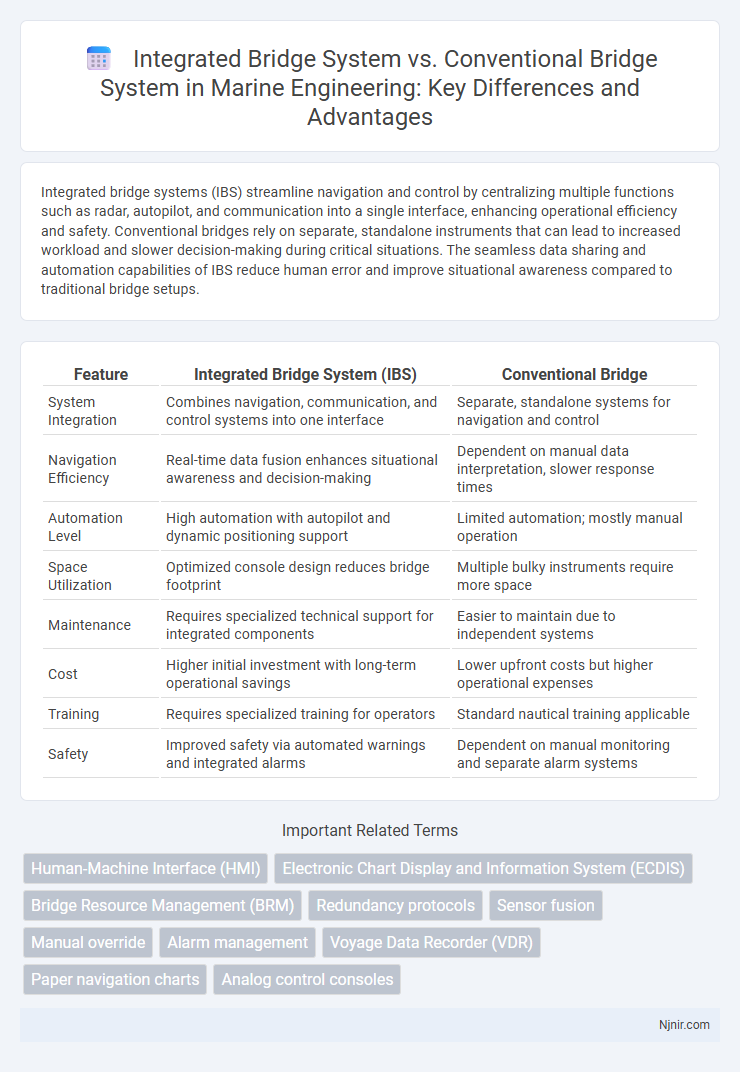

Table of Comparison

| Feature | Integrated Bridge System (IBS) | Conventional Bridge |

|---|---|---|

| System Integration | Combines navigation, communication, and control systems into one interface | Separate, standalone systems for navigation and control |

| Navigation Efficiency | Real-time data fusion enhances situational awareness and decision-making | Dependent on manual data interpretation, slower response times |

| Automation Level | High automation with autopilot and dynamic positioning support | Limited automation; mostly manual operation |

| Space Utilization | Optimized console design reduces bridge footprint | Multiple bulky instruments require more space |

| Maintenance | Requires specialized technical support for integrated components | Easier to maintain due to independent systems |

| Cost | Higher initial investment with long-term operational savings | Lower upfront costs but higher operational expenses |

| Training | Requires specialized training for operators | Standard nautical training applicable |

| Safety | Improved safety via automated warnings and integrated alarms | Dependent on manual monitoring and separate alarm systems |

Overview of Integrated Bridge Systems (IBS)

Integrated Bridge Systems (IBS) centralize navigation, communication, and control functions into a unified platform, enhancing situational awareness and operational efficiency on modern vessels. IBS consolidates radar, electronic chart display and information systems (ECDIS), autopilot, and alarm monitoring into a single interface, reducing crew workload and improving decision-making speed. Unlike conventional bridges, which rely on separate, standalone devices, IBS enables seamless data sharing and real-time integration, promoting safer and more efficient ship navigation.

Conventional Bridge Systems: Key Features

Conventional bridge systems rely on separate, standalone components such as radar, gyrocompass, echo sounders, and autopilots, each operated independently by the crew. These systems require manual data integration and extensive cross-checking, increasing the risk of human error and workload during navigation. Despite their reliability and straightforward design, conventional bridges lack the centralized control and ergonomic interface found in integrated bridge systems.

Technological Components in IBS vs Conventional Bridges

Integrated Bridge Systems (IBS) incorporate advanced technological components such as radar, electronic chart display and information systems (ECDIS), autopilot, and centralized control interfaces, enhancing situational awareness and navigation efficiency. Conventional bridges rely on standalone instruments and manual monitoring, including separate radar units, analog gauges, and traditional navigational aids, which can limit real-time data integration. The centralized data fusion in IBS enables streamlined decision-making and improved safety compared to the fragmented systems of conventional bridges.

Navigation Efficiency and Safety Enhancements

Integrated bridge systems streamline navigation by consolidating radar, GPS, and ECDIS data into a centralized interface, significantly reducing human error and enhancing situational awareness. Conventional bridges rely on separate, manually monitored instruments, which can lead to slower decision-making and increased risk during complex maneuvers. The integration of advanced automation and real-time data fusion in integrated bridge systems directly improves safety by enabling faster response times and more precise vessel control.

Crew Training and Human-Machine Interface

Integrated Bridge Systems (IBS) streamline crew training by consolidating navigation, communication, and monitoring functions into a unified Human-Machine Interface (HMI), which reduces complexity and enhances situational awareness. Conventional bridges, with separate equipment and fragmented controls, require more extensive training to manage multiple independent systems and increase the potential for human error. Advanced IBS HMIs incorporate ergonomic design and automated alerts that facilitate faster decision-making and improve overall operational safety for the crew.

Maintenance and Lifecycle Costs

Integrated bridge systems (IBS) significantly reduce maintenance and lifecycle costs compared to conventional bridge setups by consolidating navigation, communication, and monitoring functions into a centralized platform, which simplifies troubleshooting and software updates. Conventional bridge systems involve multiple independent components, leading to higher maintenance expenses, increased redundancy, and more frequent calibration or replacement cycles. The streamlined architecture of IBS promotes longer service intervals and overall lower total cost of ownership, benefiting fleet operators focused on operational efficiency and cost management.

System Integration and Operational Flexibility

Integrated bridge systems (IBS) combine radar, navigation, communication, and control functions into a unified interface, enhancing situational awareness and reducing human error. Conventional bridge systems operate with separate, stand-alone instruments, requiring manual coordination which can increase workload and response time. IBS offers superior operational flexibility by enabling centralized monitoring and automatic data fusion, improving decision-making and reducing the risk of navigational incidents.

Regulatory Compliance and Classification Standards

Integrated bridge systems (IBS) streamline regulatory compliance by consolidating navigation, communication, and monitoring functions into a unified platform, enhancing situational awareness in accordance with IMO and SOLAS standards. Conventional bridges rely on separate systems that can complicate adherence to classification society requirements such as those from ABS, DNV GL, and Lloyd's Register. Classification standards increasingly favor IBS for improved safety, reliability, and ease of inspection, facilitating certification processes while ensuring compliance with updated maritime regulations.

Retrofit Challenges and Upgrade Potential

Retrofitting an integrated bridge system (IBS) involves challenges such as complex software integration, compatibility with existing sensors, and increased training demands for crew accustomed to conventional bridge operations. Conventional bridge retrofits typically require extensive hardware replacements and can disrupt navigation during installation but offer more straightforward mechanical upgrades. The upgrade potential of IBS outweighs conventional bridges by enabling seamless integration of multiple navigation sensors, advanced automation, and real-time data sharing, enhancing situational awareness and operational efficiency.

Future Trends in Bridge System Innovation

Future trends in bridge system innovation emphasize the integration of digital technologies, advanced automation, and enhanced situational awareness in integrated bridge systems (IBS), surpassing the manual controls and isolated components of conventional bridges. Integration of AI-driven decision support tools and augmented reality displays in IBS enables improved navigational safety and operational efficiency, paving the way for autonomous and semi-autonomous vessel operations. The shift towards network-centric operations, with real-time data sharing between ship systems and shore-based control centers, is expected to redefine maritime bridge operations and maintenance strategies.

Human-Machine Interface (HMI)

Integrated bridge systems enhance Human-Machine Interface (HMI) by consolidating controls and displays into a unified platform, improving situational awareness and reducing operator workload compared to conventional bridges with disparate, standalone instruments.

Electronic Chart Display and Information System (ECDIS)

Integrated Bridge Systems (IBS) enhance navigational safety by seamlessly integrating Electronic Chart Display and Information Systems (ECDIS) with radar, autopilot, and other sensors, unlike Conventional Bridges which operate ECDIS as standalone units with limited data fusion.

Bridge Resource Management (BRM)

Integrated bridge systems enhance Bridge Resource Management by centralizing navigation and communication controls, improving situational awareness and decision-making compared to conventional bridge setups.

Redundancy protocols

Integrated bridge systems implement advanced redundancy protocols such as dual data buses and automatic failover mechanisms, significantly enhancing navigational reliability compared to the limited backup options in conventional bridge systems.

Sensor fusion

Integrated Bridge Systems enhance navigational accuracy by employing advanced sensor fusion technologies that combine radar, GPS, AIS, and gyrocompass data, whereas conventional bridges rely on individual sensors with limited data integration.

Manual override

Integrated bridge systems enhance safety by allowing seamless manual override of automated controls, whereas conventional bridges rely primarily on manual operation with limited automation integration.

Alarm management

Integrated bridge systems enhance alarm management by consolidating alerts from multiple sources into a centralized interface, improving situational awareness and reducing operator response time compared to conventional bridge systems.

Voyage Data Recorder (VDR)

Voyage Data Recorder (VDR) in Integrated Bridge Systems offers enhanced real-time data integration and centralized monitoring compared to conventional bridge systems, improving navigational safety and incident analysis.

Paper navigation charts

Integrated bridge systems enhance navigational accuracy and safety by utilizing digital paper navigation charts, while conventional bridges rely on traditional paper charts prone to human error and slower updates.

Analog control consoles

Analog control consoles in conventional bridge systems rely on manual operation and discrete instrumentation, whereas integrated bridge systems utilize digital interfaces to centralize controls and enhance operational efficiency.

Integrated bridge system vs Conventional bridge Infographic

njnir.com

njnir.com