Azimuth thrusters provide superior maneuverability and efficiency by allowing 360-degree rotation, making them ideal for precise vessel positioning and dynamic navigation. Tunnel thrusters are fixed in position within the hull and offer lateral thrust primarily for docking and low-speed maneuvers, with less impact on overall propulsion compared to azimuth thrusters. Choosing between the two depends on operational requirements, with azimuth thrusters favored for versatile movement and tunnel thrusters suited for enhanced side-to-side control during port operations.

Table of Comparison

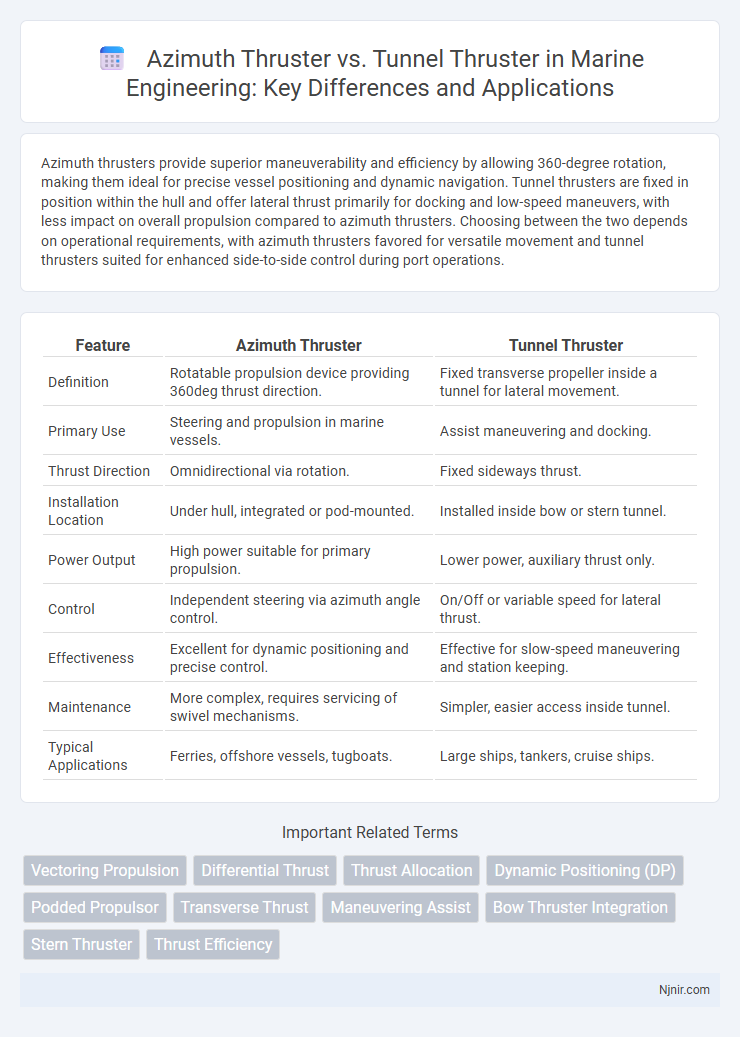

| Feature | Azimuth Thruster | Tunnel Thruster |

|---|---|---|

| Definition | Rotatable propulsion device providing 360deg thrust direction. | Fixed transverse propeller inside a tunnel for lateral movement. |

| Primary Use | Steering and propulsion in marine vessels. | Assist maneuvering and docking. |

| Thrust Direction | Omnidirectional via rotation. | Fixed sideways thrust. |

| Installation Location | Under hull, integrated or pod-mounted. | Installed inside bow or stern tunnel. |

| Power Output | High power suitable for primary propulsion. | Lower power, auxiliary thrust only. |

| Control | Independent steering via azimuth angle control. | On/Off or variable speed for lateral thrust. |

| Effectiveness | Excellent for dynamic positioning and precise control. | Effective for slow-speed maneuvering and station keeping. |

| Maintenance | More complex, requires servicing of swivel mechanisms. | Simpler, easier access inside tunnel. |

| Typical Applications | Ferries, offshore vessels, tugboats. | Large ships, tankers, cruise ships. |

Overview of Azimuth and Tunnel Thrusters

Azimuth thrusters are marine propulsion units capable of 360-degree rotation, providing enhanced maneuverability and precise directional control by vectoring thrust in any direction. Tunnel thrusters are fixed propellers installed in transverse tunnels within the hull, offering lateral thrust primarily for docking and slow-speed maneuvering. While azimuth thrusters serve as main propulsion systems with high efficiency and dynamic positioning capabilities, tunnel thrusters are auxiliary devices designed to improve ship handling in tight spaces.

Key Design Differences

Azimuth thrusters feature a 360-degree rotating pod that enables precise maneuverability by directing thrust in any horizontal direction, while tunnel thrusters are fixed units embedded in a ship's hull, pushing water sideways through a tunnel to aid in docking and low-speed control. Azimuth thrusters integrate propulsion and steering into a single system, typically used for dynamic positioning and high-mobility vessels; tunnel thrusters function primarily as auxiliary devices for lateral movement without affecting forward propulsion. The design difference lies in azimuth thrusters' external pod-mounted configuration versus the tunnel thrusters' internal hull tunnel placement, influencing performance, installation complexity, and vessel operational roles.

Operational Principles

Azimuth thrusters operate by rotating 360 degrees around a vertical axis, allowing for precise maneuverability and thrust direction control, ideal for dynamic positioning and complex navigation tasks. Tunnel thrusters are fixed propellers installed transversely within a tunnel in the hull, generating lateral thrust primarily for low-speed maneuvering, such as docking and station-keeping. The azimuth thruster integrates propulsion and steering within a single unit, while the tunnel thruster functions solely as a lateral thruster without providing forward propulsion.

Maneuverability and Vessel Control

Azimuth thrusters provide superior maneuverability and vessel control by rotating 360 degrees, enabling precise thrust direction and enhanced steering capabilities in tight spaces and complex navigational environments. Tunnel thrusters, typically fixed transversely within the hull, offer lateral thrust that assists with docking and slow-speed maneuvers but lack the comprehensive directional control of azimuth thrusters. The ability of azimuth thrusters to generate thrust in any horizontal direction considerably improves handling in adverse conditions and during dynamic positioning operations.

Installation and Space Requirements

Azimuth thrusters require extensive structural modifications and space below the hull due to their larger housing and rotating mechanisms, making installation more complex compared to tunnel thrusters. Tunnel thrusters are installed transversely within a dedicated tunnel in the hull, occupying less internal volume and simplifying retrofitting in existing vessels. The compact design of tunnel thrusters favors tight installations, while azimuth thrusters need clearances for 360-degree rotation and drive components, influencing ship design and operational space allocation.

Energy Efficiency and Power Consumption

Azimuth thrusters offer superior energy efficiency compared to tunnel thrusters due to their 360-degree rotation capability, enabling precise maneuvering with reduced power output. Tunnel thrusters often consume more power as they rely on fixed, transverse propulsion, leading to higher drag and less effective thrust during slow-speed maneuvers. Optimizing vessel performance with azimuth thrusters can result in significant fuel savings and lower operational costs.

Maintenance and Serviceability

Azimuth thrusters feature complex swivel mechanisms requiring regular lubrication and inspection to maintain optimal performance, with maintenance often involving access to underwater components. Tunnel thrusters, embedded within the hull, allow for easier access during drydocking but may experience increased wear due to debris accumulation, necessitating frequent cleaning. Both systems benefit from predictive maintenance practices leveraging condition monitoring to reduce downtime and extend service life.

Typical Applications in Marine Vessels

Azimuth thrusters are commonly utilized in dynamic positioning systems for offshore vessels, tugboats, and ferries, offering 360-degree maneuverability that enhances precise navigation and station keeping. Tunnel thrusters are typically installed in bow or stern sections of larger ships, such as cargo vessels and cruise ships, to provide lateral thrust for docking and slow-speed maneuvering in tight spaces. Both thruster types improve vessel handling, but azimuth thrusters excel in scenarios requiring continuous directional control while tunnel thrusters support short bursts of lateral movement during port operations.

Cost Considerations and Investment

Azimuth thrusters generally require higher initial investment costs due to their complex design and advanced maneuverability capabilities compared to tunnel thrusters. Maintenance expenses for azimuth thrusters can also be greater because of their intricate components and propulsion mechanisms. Tunnel thrusters offer a more cost-effective solution for smaller vessels or applications with limited maneuvering demands, resulting in lower upfront and maintenance expenditures.

Choosing the Right Thruster for Marine Projects

Selecting the right thruster for marine projects depends on operational requirements and vessel type; azimuth thrusters offer 360-degree rotation providing superior maneuverability and efficiency for dynamic positioning and propulsion tasks. Tunnel thrusters are fixed within a tunnel perpendicular to the hull, ideal for low-speed lateral movements, docking, and station keeping in smaller vessels or tugs. Evaluating factors like vessel size, maneuvering precision, installation space, and energy consumption is critical for optimizing thruster performance in marine applications.

Vectoring Propulsion

Azimuth thrusters provide 360-degree vectoring propulsion for enhanced maneuverability, whereas tunnel thrusters offer limited, fixed-direction lateral thrust primarily for low-speed docking and station-keeping.

Differential Thrust

Azimuth thrusters provide enhanced differential thrust by allowing 360-degree rotation for precise maneuvering, whereas tunnel thrusters generate limited lateral thrust through fixed tunnels, making them less effective for dynamic directional control.

Thrust Allocation

Azimuth thrusters provide 360-degree thrust vectoring for dynamic thrust allocation, while tunnel thrusters deliver lateral thrust within a fixed tunnel, primarily enhancing maneuverability during low-speed operations.

Dynamic Positioning (DP)

Azimuth thrusters provide superior Dynamic Positioning (DP) accuracy and maneuverability compared to tunnel thrusters due to their 360-degree rotation and higher thrust efficiency.

Podded Propulsor

Podded propulsors like azimuth thrusters offer 360-degree rotational maneuverability and higher efficiency compared to tunnel thrusters, which provide limited lateral thrust for low-speed docking operations.

Transverse Thrust

Azimuth thrusters provide 360-degree transverse thrust enabling superior maneuverability compared to tunnel thrusters, which generate limited transverse thrust primarily for low-speed lateral movements.

Maneuvering Assist

Azimuth thrusters provide 360-degree directional thrust for precise maneuvering assist, while tunnel thrusters offer lateral thrust primarily for low-speed maneuvering and docking support.

Bow Thruster Integration

Azimuth thrusters offer enhanced maneuverability with 360-degree rotation, making them more effective for bow thruster integration compared to fixed-direction tunnel thrusters that provide lateral thrust only.

Stern Thruster

Stern thrusters, often implemented as tunnel thrusters, provide lateral maneuverability at the ship's stern, while azimuth thrusters deliver 360-degree propulsion control by rotating the entire unit, offering enhanced steering flexibility.

Thrust Efficiency

Azimuth thrusters generally offer higher thrust efficiency during vessel maneuvering compared to tunnel thrusters due to their ability to rotate 360 degrees and provide directed propulsion.

azimuth thruster vs tunnel thruster Infographic

njnir.com

njnir.com