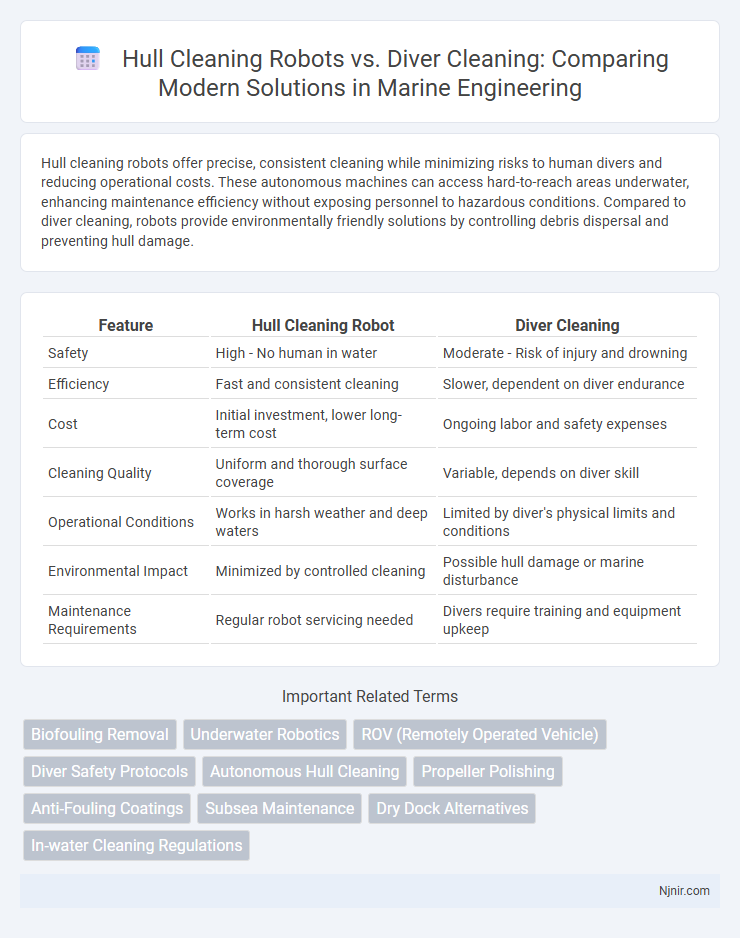

Hull cleaning robots offer precise, consistent cleaning while minimizing risks to human divers and reducing operational costs. These autonomous machines can access hard-to-reach areas underwater, enhancing maintenance efficiency without exposing personnel to hazardous conditions. Compared to diver cleaning, robots provide environmentally friendly solutions by controlling debris dispersal and preventing hull damage.

Table of Comparison

| Feature | Hull Cleaning Robot | Diver Cleaning |

|---|---|---|

| Safety | High - No human in water | Moderate - Risk of injury and drowning |

| Efficiency | Fast and consistent cleaning | Slower, dependent on diver endurance |

| Cost | Initial investment, lower long-term cost | Ongoing labor and safety expenses |

| Cleaning Quality | Uniform and thorough surface coverage | Variable, depends on diver skill |

| Operational Conditions | Works in harsh weather and deep waters | Limited by diver's physical limits and conditions |

| Environmental Impact | Minimized by controlled cleaning | Possible hull damage or marine disturbance |

| Maintenance Requirements | Regular robot servicing needed | Divers require training and equipment upkeep |

Introduction to Hull Cleaning Methods

Hull cleaning methods primarily include robotic systems and traditional diver cleaning, each offering distinct operational advantages. Robotic hull cleaning robots utilize advanced sensors and automation to efficiently remove biofouling, reducing human risk and improving consistency in maintenance schedules. Diver cleaning remains a flexible approach, allowing for detailed inspection and targeted cleaning in complex hull areas where robots may face limitations.

Overview of Hull Cleaning Robots

Hull cleaning robots utilize advanced autonomous technology to efficiently remove biofouling and marine growth from ship hulls, reducing fuel consumption and maintenance costs. Equipped with sensors and brushes, these robots perform precision cleaning without damaging hull coatings, enhancing vessel performance and environmental compliance. Compared to diver cleaning, hull cleaning robots offer safer, faster operations with consistent results and minimal downtime.

Diver-Based Hull Cleaning Explained

Diver-based hull cleaning involves specialized personnel manually scraping and scrubbing the vessel's hull to remove marine growth, using handheld tools and non-abrasive cleaning substances that protect the ship's coating. This method allows for precise inspection and immediate identification of hull damage or corrosion, ensuring targeted maintenance alongside cleaning. Although diver cleaning can be time-consuming and weather-dependent, it remains a preferred approach for complex surfaces and sensitive materials where robotic tools may lack finesse.

Efficiency Comparison: Robot vs Diver

Hull cleaning robots operate with consistent precision and can work continuously for extended periods, reducing downtime and increasing efficiency compared to divers who require breaks and have limited underwater endurance. Robots utilize advanced sensors and AI to navigate complex hull surfaces, ensuring thorough cleaning while minimizing damage risks that may occur with manual diver methods. This automation significantly reduces labor costs and allows vessels to spend less time in dry dock, optimizing overall operational efficiency.

Impact on Marine Life and Environment

Hull cleaning robots minimize environmental impact by reducing the need for chemical treatments and limiting disturbance to marine ecosystems during maintenance. Diver cleaning often causes localized disruption to marine life through physical contact, increased sediment suspension, and potential harm to sensitive organisms. Utilizing automated hull cleaning technology supports sustainable practices by protecting underwater habitats and promoting cleaner operations in the shipping industry.

Operational Safety and Risk Factors

Hull cleaning robots significantly enhance operational safety by eliminating the need for human divers to enter hazardous underwater environments, reducing risks such as decompression sickness, drowning, and exposure to marine life. These autonomous systems use advanced sensors and real-time monitoring to navigate and clean hull surfaces efficiently, minimizing human error and ensuring consistent performance. Diver cleaning, while effective, involves higher safety risks due to physical strain, limited visibility, and reliance on manual operation in unpredictable underwater conditions.

Cost Analysis: Robots Versus Divers

Hull cleaning robots offer a cost-effective alternative to diver cleaning by reducing labor expenses and minimizing vessel downtime, with initial investments typically ranging from $50,000 to $150,000 depending on robot capabilities. Diver cleaning costs vary widely based on depth, water conditions, and safety requirements but generally amount to $500 to $1,200 per hour, making routine maintenance more expensive over time. Robots ensure consistent cleaning cycles and lower long-term operational costs, while divers incur variable expenses linked to personnel, insurance, and dive support equipment.

Regulatory Compliance and Standards

Hull cleaning robots ensure consistent adherence to international maritime environmental regulations such as the International Convention on the Control of Harmful Anti-fouling Systems on Ships (AFS Convention) by minimizing biofouling and preventing the spread of invasive aquatic species. Diver cleaning must comply with strict occupational safety standards, including the Occupational Safety and Health Administration (OSHA) guidelines, to protect divers from underwater hazards and toxic substances during manual cleaning operations. Automated hull cleaning systems offer documented traceability and precise cleaning validation, facilitating easier regulatory reporting compared to manual diver-based cleaning methods.

Technological Advancements in Hull Cleaning

Hull cleaning robots leverage advanced robotics and AI-driven navigation systems to enhance precision and efficiency, surpassing traditional diver methods in safety and operational consistency. Equipped with suction-based mobility and high-resolution sensors, these robots can clean complex hull geometries without damaging sensitive coatings. Technological advancements have also enabled remote monitoring and real-time data analytics, optimizing maintenance schedules and extending vessel lifespan.

Future Trends in Marine Hull Maintenance

Hull cleaning robots are rapidly transforming marine hull maintenance by offering AI-driven precision and eco-friendly biofouling removal, significantly reducing manual labor and operational downtime. Emerging trends emphasize autonomous underwater navigation, real-time data analytics for hull condition monitoring, and integration with smart vessel technologies to enhance cleaning efficacy and predictive maintenance. Diver cleaning remains relevant for complex surfaces but is gradually being supplemented or replaced by advanced robotic systems that boost safety and operational efficiency in the marine sector.

Biofouling Removal

Hull cleaning robots effectively remove biofouling with precision and reduced environmental impact compared to traditional diver cleaning methods, improving vessel efficiency and lowering maintenance costs.

Underwater Robotics

Underwater robotics Hull Cleaning Robots offer efficient, eco-friendly maintenance by automating biofouling removal, reducing human risk and operational costs compared to traditional diver cleaning methods.

ROV (Remotely Operated Vehicle)

Hull cleaning using Remotely Operated Vehicles (ROVs) offers superior efficiency, safety, and environmental control compared to traditional diver cleaning by automating debris removal and minimizing human risk.

Diver Safety Protocols

Hull cleaning robots significantly reduce diver safety risks by minimizing the need for underwater human intervention, enhancing adherence to strict diver safety protocols.

Autonomous Hull Cleaning

Autonomous hull cleaning robots enhance efficiency and safety by performing precise, eco-friendly underwater maintenance without human divers.

Propeller Polishing

Hull cleaning robots deliver precise and efficient propeller polishing by using advanced sensors and automated brushes, significantly reducing downtime and human risk compared to traditional diver cleaning methods.

Anti-Fouling Coatings

Hull cleaning robots effectively maintain anti-fouling coatings by providing consistent, controlled cleaning that minimizes coating damage compared to diver cleaning, which risks abrasion and uneven removal.

Subsea Maintenance

Hull cleaning robots enhance subsea maintenance by increasing efficiency, reducing operational risks, and minimizing downtime compared to traditional diver cleaning methods.

Dry Dock Alternatives

Hull cleaning robots offer a cost-effective, eco-friendly dry dock alternative by performing efficient underwater maintenance without the need for vessel dewatering or diver deployment.

In-water Cleaning Regulations

Hull cleaning robots comply with strict in-water cleaning regulations by minimizing environmental impact and preventing the release of invasive species compared to traditional diver cleaning methods.

Hull Cleaning Robot vs Diver Cleaning Infographic

njnir.com

njnir.com