Pneumatic controls in marine engineering offer robust performance in harsh environments due to their resistance to moisture and electromagnetic interference, ensuring reliable operation of valves and actuators. Electronic controls provide precise and rapid response capabilities with advanced programmability, enabling sophisticated automation and system monitoring. Selecting between pneumatic and electronic controls depends on the specific vessel requirements, balancing durability with control accuracy and integration needs.

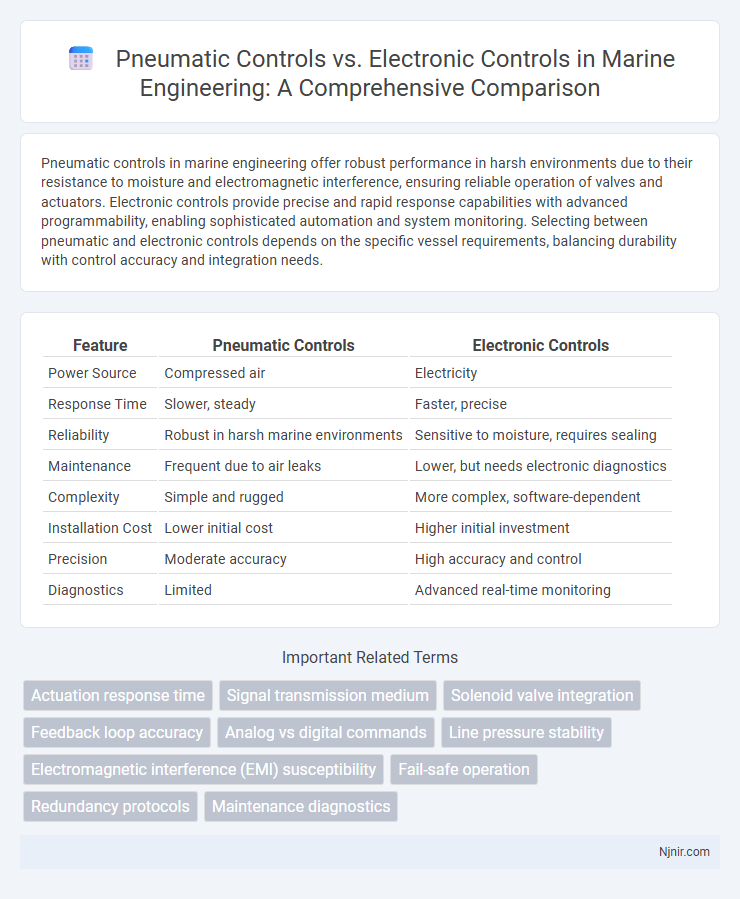

Table of Comparison

| Feature | Pneumatic Controls | Electronic Controls |

|---|---|---|

| Power Source | Compressed air | Electricity |

| Response Time | Slower, steady | Faster, precise |

| Reliability | Robust in harsh marine environments | Sensitive to moisture, requires sealing |

| Maintenance | Frequent due to air leaks | Lower, but needs electronic diagnostics |

| Complexity | Simple and rugged | More complex, software-dependent |

| Installation Cost | Lower initial cost | Higher initial investment |

| Precision | Moderate accuracy | High accuracy and control |

| Diagnostics | Limited | Advanced real-time monitoring |

Introduction to Pneumatic and Electronic Controls in Marine Engineering

Pneumatic controls in marine engineering utilize compressed air to operate valves, actuators, and other machinery, offering reliability in harsh marine environments due to their resistance to moisture and electrical interference. Electronic controls rely on sensors, processors, and electrical signals to manage shipboard systems with higher precision and faster response times, supporting advanced automation and integration capabilities. Both control types are essential in marine engineering, with pneumatic controls favored for simplicity and robustness, while electronic controls enable sophisticated monitoring and control functions.

Principles of Operation: Pneumatic vs Electronic Control Systems

Pneumatic control systems operate by modulating air pressure through valves and actuators to regulate mechanical processes, relying on compressed air as the control medium. Electronic control systems use electrical signals and electronic components such as sensors, microcontrollers, and actuators to achieve precise and rapid control of processes. While pneumatic controls offer durability in harsh environments and simplicity, electronic controls provide greater accuracy, programmability, and integration with digital systems.

Key Components of Marine Pneumatic Controls

Marine pneumatic controls rely on key components such as compressed air supply systems, pneumatic actuators, control valves, and pressure regulators to manage shipboard machinery and systems efficiently. These components enable precise modulation of airflow and pressure, ensuring reliable operation in harsh marine environments. Compared to electronic controls, pneumatic systems offer robustness and intrinsic safety in explosive atmospheres, making them vital for critical marine applications.

Core Elements of Marine Electronic Controls

Marine electronic controls integrate sensors, microprocessors, and actuators to provide precise throttle and steering adjustments, enhancing vessel responsiveness and fuel efficiency. Core elements include advanced feedback mechanisms, real-time data processing units, and corrosion-resistant connectors designed to withstand harsh marine environments. This technology offers superior reliability and fine-tuned control compared to pneumatic systems, reducing maintenance and improving operational safety.

Performance Comparison in Marine Environments

Pneumatic controls in marine environments offer high reliability and resistance to moisture, corrosion, and electromagnetic interference, making them suitable for harsh conditions. Electronic controls provide greater precision, faster response times, and easier integration with modern automation systems but may require additional protection against saltwater exposure and electrical disturbances. Performance in marine applications depends on balancing robustness and accuracy, with pneumatic systems favored for durability and electronics preferred for advanced control strategies.

Reliability and Maintenance Considerations

Pneumatic controls often offer greater reliability in harsh or explosive environments due to their simplicity and resistance to electrical interference, while electronic controls provide higher precision and adaptability but may require more frequent maintenance due to sensitive components. Maintenance of pneumatic systems typically involves checking for air leaks and compressor functionality, whereas electronic controls demand regular software updates and calibration to prevent faults. Choosing between pneumatic and electronic controls depends on operational conditions, desired accuracy, and maintenance resources available.

Energy Efficiency and Power Requirements

Pneumatic controls typically consume more energy due to continuous compressed air demand, resulting in higher operating costs and inefficiencies in large-scale systems. Electronic controls offer enhanced energy efficiency by utilizing low voltage and reduced power consumption, enabling precise control with minimal waste. Power requirements for pneumatic systems are substantial, often necessitating bulky compressors, whereas electronic controls leverage compact, energy-saving components suited for automation and smart technologies.

Integration and Compatibility with Existing Systems

Pneumatic controls offer seamless integration with legacy industrial systems due to their reliance on air pressure signals, which are widely used in older manufacturing setups. Electronic controls provide greater compatibility with modern digital infrastructure, enabling advanced data communication protocols such as Modbus, BACnet, and Ethernet/IP for real-time monitoring and automation. The choice between pneumatic and electronic controls depends heavily on the specific requirements for system retrofitting and the existing technological ecosystem's architecture.

Safety and Regulatory Compliance

Pneumatic controls offer inherent safety advantages in hazardous environments due to their resistance to electrical sparks and interference, reducing the risk of ignition in explosive atmospheres. Electronic controls provide precise monitoring and automated safety features enabling compliance with stringent regulatory standards such as OSHA and IECEx, enhancing system reliability and fault detection. Choosing between pneumatic and electronic controls depends on the specific industrial safety requirements and the regulatory framework governing the application.

Future Trends in Marine Control Technologies

Future trends in marine control technologies emphasize the integration of electronic controls due to their superior precision, remote monitoring capabilities, and adaptability with IoT systems. Pneumatic controls, while valued for simplicity and reliability, are gradually being phased out in favor of smart electronic systems that enhance predictive maintenance and fuel efficiency. Advances in sensor technology and AI-driven analytics are accelerating the shift toward fully automated, data-driven marine vessel management.

Actuation response time

Pneumatic controls typically exhibit slower actuation response times ranging from 100 to 300 milliseconds, whereas electronic controls achieve faster response times often under 50 milliseconds, enhancing precision and efficiency in automated systems.

Signal transmission medium

Pneumatic controls use compressed air as the signal transmission medium, offering robustness in hazardous environments, while electronic controls rely on electrical signals for faster, more precise communication and integration with digital systems.

Solenoid valve integration

Solenoid valve integration in electronic controls offers faster response times, precise modulation, and easier automation compared to the slower, less accurate actuation of pneumatic control systems.

Feedback loop accuracy

Electronic controls provide higher feedback loop accuracy than pneumatic controls due to faster response times and greater precision in signal processing.

Analog vs digital commands

Pneumatic controls primarily use analog pressure signals for continuous control, whereas electronic controls utilize digital commands for precise, programmable, and real-time system management.

Line pressure stability

Pneumatic controls often provide more stable line pressure in harsh environments due to their inherent resistance to electrical interference compared to electronic controls.

Electromagnetic interference (EMI) susceptibility

Pneumatic controls exhibit significantly lower susceptibility to electromagnetic interference (EMI) compared to electronic controls, making them more reliable in environments with high EMI levels.

Fail-safe operation

Pneumatic controls provide inherent fail-safe operation by using air pressure loss to trigger default safety states, whereas electronic controls rely on programmed logic and backup power systems to maintain fail-safe conditions.

Redundancy protocols

Pneumatic controls rely on mechanical redundancy protocols such as pressure backup and multiple valve stages, while electronic controls implement digital redundancy through sensor fusion, failover algorithms, and real-time diagnostics to ensure system reliability.

Maintenance diagnostics

Pneumatic controls require regular manual inspection for leaks and pressure inconsistencies, whereas electronic controls offer advanced real-time diagnostics and remote monitoring capabilities, significantly enhancing maintenance efficiency.

pneumatic controls vs electronic controls Infographic

njnir.com

njnir.com