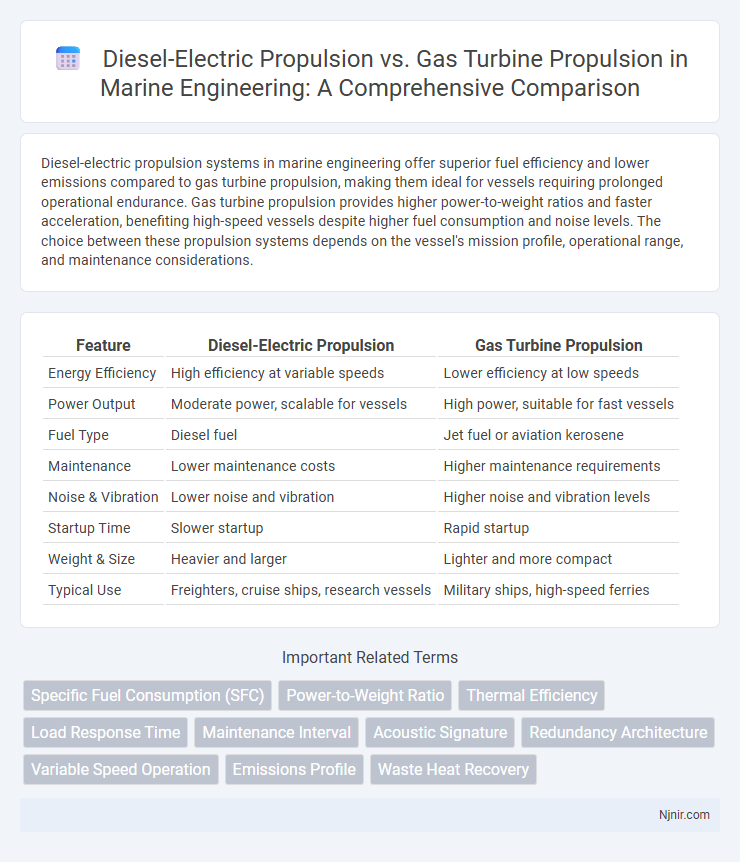

Diesel-electric propulsion systems in marine engineering offer superior fuel efficiency and lower emissions compared to gas turbine propulsion, making them ideal for vessels requiring prolonged operational endurance. Gas turbine propulsion provides higher power-to-weight ratios and faster acceleration, benefiting high-speed vessels despite higher fuel consumption and noise levels. The choice between these propulsion systems depends on the vessel's mission profile, operational range, and maintenance considerations.

Table of Comparison

| Feature | Diesel-Electric Propulsion | Gas Turbine Propulsion |

|---|---|---|

| Energy Efficiency | High efficiency at variable speeds | Lower efficiency at low speeds |

| Power Output | Moderate power, scalable for vessels | High power, suitable for fast vessels |

| Fuel Type | Diesel fuel | Jet fuel or aviation kerosene |

| Maintenance | Lower maintenance costs | Higher maintenance requirements |

| Noise & Vibration | Lower noise and vibration | Higher noise and vibration levels |

| Startup Time | Slower startup | Rapid startup |

| Weight & Size | Heavier and larger | Lighter and more compact |

| Typical Use | Freighters, cruise ships, research vessels | Military ships, high-speed ferries |

Introduction to Marine Propulsion Systems

Diesel-electric propulsion systems utilize diesel engines to generate electricity, which then powers electric motors driving the ship's propellers, offering enhanced fuel efficiency and reduced emissions in marine vessels. Gas turbine propulsion relies on high-speed turbines producing direct mechanical power, enabling greater power-to-weight ratios and faster speeds, commonly used in naval and high-speed commercial ships. Both systems play crucial roles in marine propulsion, balancing factors like operational efficiency, maintenance demands, and vessel performance requirements.

Overview of Diesel-Electric Propulsion

Diesel-electric propulsion systems combine diesel engines with electric generators to produce electricity that powers electric motors connected to the ship's propellers, offering enhanced fuel efficiency and reduced emissions compared to traditional mechanical drive systems. This configuration enables flexible power management, quieter operation, and improved maneuverability, making it ideal for various naval and commercial vessels. The modular design of diesel-electric systems supports easier maintenance and integration with renewable energy sources, contributing to sustainable maritime operations.

Overview of Gas Turbine Propulsion

Gas turbine propulsion utilizes high-speed turbines powered by the combustion of fuel, offering a lightweight and compact design ideal for high-speed maritime and aerospace applications. This propulsion system delivers rapid acceleration and high power-to-weight ratios but tends to consume more fuel and requires advanced maintenance compared to diesel-electric systems. Its efficiency peaks at high speeds, making it suitable for vessels and aircraft prioritizing performance over fuel economy.

Energy Efficiency and Fuel Consumption

Diesel-electric propulsion systems offer superior energy efficiency at lower speeds and partial loads due to their ability to optimize engine operation and recover energy, resulting in reduced fuel consumption compared to gas turbine propulsion. Gas turbines perform better at high speeds and continuous full-load operations but generally exhibit higher fuel consumption during varied operating conditions because of lower part-load efficiency. Studies show that diesel-electric systems can achieve fuel savings of up to 20-30% in mixed operational profiles, making them more economical for vessels with frequent speed changes.

Operational Flexibility and Performance

Diesel-electric propulsion systems offer enhanced operational flexibility with their ability to vary power output efficiently across a wide range of speeds, making them ideal for vessels requiring frequent speed changes and improved fuel economy at low to medium power levels. Gas turbine propulsion provides superior high-speed performance and rapid acceleration, favored in applications demanding swift response and high power-to-weight ratios. Diesel-electric systems typically excel in fuel efficiency and noise reduction during low-speed cruising, whereas gas turbines deliver peak performance in high-speed naval and commercial operations.

Maintenance and Reliability

Diesel-electric propulsion systems offer lower maintenance costs and higher reliability due to fewer moving parts and simpler mechanical configurations compared to gas turbine propulsion. Gas turbines require frequent inspections and component replacements because of high operating temperatures and rotational speeds, leading to increased downtime. Reliable diesel-electric systems enhance operational availability and reduce lifecycle expenditures, especially in applications demanding extended continuous operation.

Environmental Impact and Emissions

Diesel-electric propulsion systems produce lower nitrogen oxides (NOx) and particulate matter (PM) emissions compared to gas turbine propulsion, making them more environmentally friendly for marine and rail applications. Gas turbines typically generate higher carbon dioxide (CO2) and sulfur oxides (SOx) emissions due to higher fuel consumption and less efficient combustion processes. Advanced emission control technologies like selective catalytic reduction (SCR) and particulate filters are more effectively integrated into diesel-electric systems to reduce their overall environmental footprint.

Application Suitability in Vessel Types

Diesel-electric propulsion suits vessels requiring precise maneuverability and fuel efficiency, such as cruise ships, research vessels, and offshore supply vessels, due to its flexible power distribution and quieter operation. Gas turbine propulsion excels in high-speed vessels like military ships and fast ferries, benefiting from its high power-to-weight ratio and rapid acceleration capabilities. The choice depends on operational needs, with diesel-electric favored for endurance and variable speeds, while gas turbines are preferred for speed and quick response.

Lifecycle Costs and Economic Considerations

Diesel-electric propulsion systems typically offer lower lifecycle costs due to higher fuel efficiency, longer maintenance intervals, and reduced operational expenses compared to gas turbine propulsion. Gas turbine propulsion, while providing superior power-to-weight ratios and higher speeds, incurs higher fuel consumption and more frequent, costly maintenance, impacting total economic viability. Evaluating fuel prices, maintenance infrastructure, and operational demands is critical for determining the most cost-effective propulsion technology over the vessel's lifespan.

Future Trends in Marine Propulsion Technologies

Diesel-electric propulsion systems are increasingly favored for their fuel efficiency, lower emissions, and enhanced operational flexibility, driving innovation in hybrid configurations and advanced energy storage integration. Gas turbine propulsion continues to evolve with improvements in power density, fuel adaptability, and emissions reduction technologies, particularly for high-speed naval and commercial vessels. Future marine propulsion trends emphasize the integration of renewable energy sources, digital twin technologies, and autonomous control systems to optimize performance and sustainability.

Specific Fuel Consumption (SFC)

Diesel-electric propulsion systems typically exhibit lower Specific Fuel Consumption (SFC) values compared to gas turbine propulsion, resulting in higher fuel efficiency and operational cost savings for marine and power generation applications.

Power-to-Weight Ratio

Diesel-electric propulsion systems typically offer a higher power-to-weight ratio than gas turbine propulsion, enhancing efficiency and performance in marine and rail applications.

Thermal Efficiency

Diesel-electric propulsion systems typically achieve higher thermal efficiency, often exceeding 40%, compared to gas turbine propulsion, which generally ranges between 25% and 35% efficiency in marine applications.

Load Response Time

Diesel-electric propulsion systems typically offer faster load response times than gas turbine propulsion due to their ability to quickly adjust electrical output without the need for gradual mechanical spool-up.

Maintenance Interval

Diesel-electric propulsion systems typically offer longer maintenance intervals compared to gas turbine propulsion, reducing downtime and operational costs for maritime vessels.

Acoustic Signature

Diesel-electric propulsion systems produce lower acoustic signatures than gas turbine propulsion, enhancing stealth in naval operations due to reduced noise emissions and vibrations.

Redundancy Architecture

Diesel-electric propulsion systems offer enhanced redundancy architecture with multiple independent generators and electric motors, ensuring higher operational reliability compared to gas turbine propulsion, which relies on fewer, more centralized components.

Variable Speed Operation

Diesel-electric propulsion systems offer superior variable speed operation efficiency compared to gas turbine propulsion by enabling precise power output adjustments and improved fuel economy at low speeds.

Emissions Profile

Diesel-electric propulsion systems typically produce lower nitrogen oxide and sulfur emissions compared to gas turbine propulsion, resulting in a cleaner overall emissions profile.

Waste Heat Recovery

Diesel-electric propulsion systems achieve higher fuel efficiency and reduced emissions by effectively utilizing waste heat recovery through exhaust heat exchangers and turbochargers, whereas gas turbine propulsion typically faces challenges in waste heat capture due to higher exhaust temperatures and lower exhaust mass flow rates.

diesel-electric propulsion vs gas turbine propulsion Infographic

njnir.com

njnir.com