EEDI (Energy Efficiency Design Index) is a technical measure that evaluates a ship's design efficiency based on its CO2 emissions per ton-mile, promoting environmentally friendly construction standards. SEEMP (Ship Energy Efficiency Management Plan) focuses on operational strategies to enhance energy efficiency throughout a vessel's lifecycle, including fuel management and route optimization. Comparing both, EEDI targets shipbuilders with regulatory emission limits, while SEEMP empowers operators to implement continuous energy-saving practices onboard.

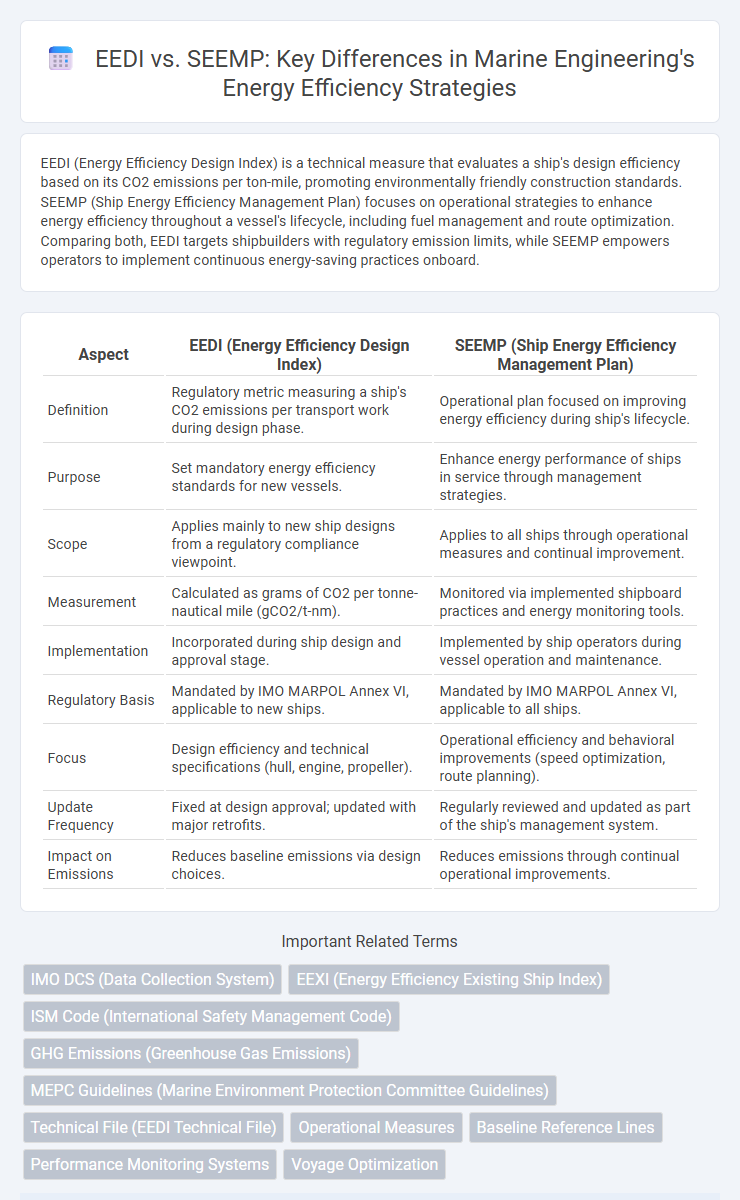

Table of Comparison

| Aspect | EEDI (Energy Efficiency Design Index) | SEEMP (Ship Energy Efficiency Management Plan) |

|---|---|---|

| Definition | Regulatory metric measuring a ship's CO2 emissions per transport work during design phase. | Operational plan focused on improving energy efficiency during ship's lifecycle. |

| Purpose | Set mandatory energy efficiency standards for new vessels. | Enhance energy performance of ships in service through management strategies. |

| Scope | Applies mainly to new ship designs from a regulatory compliance viewpoint. | Applies to all ships through operational measures and continual improvement. |

| Measurement | Calculated as grams of CO2 per tonne-nautical mile (gCO2/t-nm). | Monitored via implemented shipboard practices and energy monitoring tools. |

| Implementation | Incorporated during ship design and approval stage. | Implemented by ship operators during vessel operation and maintenance. |

| Regulatory Basis | Mandated by IMO MARPOL Annex VI, applicable to new ships. | Mandated by IMO MARPOL Annex VI, applicable to all ships. |

| Focus | Design efficiency and technical specifications (hull, engine, propeller). | Operational efficiency and behavioral improvements (speed optimization, route planning). |

| Update Frequency | Fixed at design approval; updated with major retrofits. | Regularly reviewed and updated as part of the ship's management system. |

| Impact on Emissions | Reduces baseline emissions via design choices. | Reduces emissions through continual operational improvements. |

Introduction to Marine Energy Efficiency Regulations

EEDI (Energy Efficiency Design Index) sets mandatory energy efficiency standards for new ships by regulating CO2 emissions per ton-mile, promoting greener ship designs under IMO regulations. SEEMP (Ship Energy Efficiency Management Plan) applies to all vessels, requiring operators to implement practical measures to improve energy efficiency during operations. Both frameworks form the core of the IMO's marine energy efficiency regulations, aiming to reduce the shipping industry's environmental footprint through design innovation and operational management.

Defining EEDI: Purpose and Scope

EEDI (Energy Efficiency Design Index) measures a ship's CO2 emissions relative to its transport work, quantifying the design-phase energy efficiency of new ships to enforce environmental standards and reduce greenhouse gas emissions. It applies to specific ship types and sizes, setting a baseline and progressive reduction targets aligned with IMO regulations to drive cleaner ship design. SEEMP (Ship Energy Efficiency Management Plan) complements EEDI by focusing on operational measures to improve energy efficiency throughout a ship's lifecycle rather than design alone.

SEEMP Explained: Management Plan Overview

SEEMP (Ship Energy Efficiency Management Plan) is a strategic framework designed to improve a vessel's operational energy efficiency through continuous monitoring, evaluation, and implementation of energy-saving measures. Unlike EEDI (Energy Efficiency Design Index), which mandates design-based efficiency targets for new ships, SEEMP applies to both new and existing ships by optimizing operational practices such as speed management, route optimization, and maintenance routines. This management plan fosters systematic energy use reduction, compliance with environmental regulations, and enhanced sustainability in maritime operations.

Key Differences Between EEDI and SEEMP

EEDI (Energy Efficiency Design Index) measures the energy efficiency of a ship's design by calculating CO2 emissions per ton-mile, making it a mandatory regulation for new ships under IMO guidelines, whereas SEEMP (Ship Energy Efficiency Management Plan) is a operational tool focusing on energy management practices and fuel consumption optimization applicable to all existing vessels. EEDI is a technical metric evaluated during the ship design phase, while SEEMP is a dynamic, vessel-specific plan updated regularly to improve operational efficiency. Compliance with EEDI results in design improvements, while SEEMP ensures ongoing monitoring and adoption of best practices for energy saving during ship operations.

Regulatory Framework: IMO Guidelines for EEDI and SEEMP

The Energy Efficiency Design Index (EEDI) and Ship Energy Efficiency Management Plan (SEEMP) are mandated under the International Maritime Organization (IMO) regulatory framework to reduce greenhouse gas emissions from ships. EEDI establishes technical efficiency standards for new vessels by promoting optimized design and fuel consumption, while SEEMP provides operational guidelines for existing ships to improve energy performance through monitoring and management practices. Both tools are integral to the IMO's strategy outlined in MARPOL Annex VI, supporting global maritime energy efficiency and environmental sustainability.

Implementation Procedures: EEDI vs SEEMP

EEDI implementation procedures require shipbuilders to design vessels that meet specific energy efficiency standards through technical measures such as hull design and engine performance optimization, verified during the shipbuilding phase. SEEMP implementation procedures involve ship operators developing and updating a management plan that outlines operational measures including speed optimization, route planning, and maintenance schedules aimed at improving energy efficiency throughout the vessel's operational life. EEDI focuses on regulatory compliance during design and construction, while SEEMP emphasizes continuous monitoring and operational adjustments to achieve energy savings.

Impact on Vessel Design and Operation

EEDI (Energy Efficiency Design Index) sets mandatory energy efficiency standards directly influencing new vessel designs by promoting the integration of advanced technologies such as optimized hull forms, energy-efficient engines, and alternative fuels to reduce carbon emissions. SEEMP (Ship Energy Efficiency Management Plan) targets operational improvements across both new and existing ships, focusing on strategies like voyage optimization, speed management, and maintenance practices to enhance fuel efficiency and reduce environmental impact. Together, EEDI drives innovation in shipbuilding for lower emissions, while SEEMP ensures continuous operational energy savings throughout a vessel's lifecycle.

Monitoring, Reporting, and Compliance Measures

EEDI (Energy Efficiency Design Index) establishes mandatory design-phase emission benchmarks for new ships, ensuring baseline energy performance through standardized calculations and certification during construction. SEEMP (Ship Energy Efficiency Management Plan) offers a dynamic operational framework requiring continuous monitoring, systematic reporting, and adaptive management to optimize fuel consumption and emissions throughout a ship's service life. Compliance under EEDI centers on design verification and initial certification, while SEEMP mandates ongoing data collection, voyage analysis, and periodic submission to regulatory bodies for transparent performance assessment and regulatory adherence.

Challenges and Opportunities in EEDI and SEEMP Adoption

EEDI faces challenges such as the complexity of integrating innovative technologies and the high initial costs for shipbuilders aiming to meet stringent CO2 emission targets. SEEMP adoption encounters obstacles related to consistent crew training, real-time data collection, and maintaining operational discipline across diverse fleets. Opportunities in EEDI and SEEMP include leveraging digital monitoring tools and advanced analytics to optimize energy performance, thus reducing fuel consumption and enhancing regulatory compliance for greener shipping.

Future Trends in Ship Energy Efficiency Standards

Future trends in ship energy efficiency standards emphasize tightening EEDI regulations to push for greener vessel designs that reduce carbon emissions through innovative hull forms and alternative fuels. SEEMP is evolving to integrate real-time data monitoring and AI-driven operational adjustments, enhancing dynamic energy management aboard ships. The convergence of advanced technology with stricter EEDI benchmarks aims to achieve IMO's 2050 decarbonization targets by improving both design and operational efficiency comprehensively.

IMO DCS (Data Collection System)

The IMO DCS facilitates mandatory annual data reporting to monitor and compare vessel performance under EEDI for new ships and SEEMP for operational energy efficiency management.

EEXI (Energy Efficiency Existing Ship Index)

The Energy Efficiency Existing Ship Index (EEXI) quantifies the energy efficiency of existing vessels by measuring design-related emissions, complementing the Energy Efficiency Design Index (EEDI) for new ships, while the Ship Energy Efficiency Management Plan (SEEMP) focuses on operational strategies to optimize fuel consumption and reduce emissions during ship operations.

ISM Code (International Safety Management Code)

EEDI mandates technical energy efficiency improvements for new ships, while SEEMP, aligned with the ISM Code, provides operational strategies to enhance existing vessel performance and safety management.

GHG Emissions (Greenhouse Gas Emissions)

EEDI quantifies a ship's design efficiency to reduce GHG emissions during operation, while SEEMP provides a practical framework for continuous monitoring and managing a ship's operational activities to minimize GHG emissions.

MEPC Guidelines (Marine Environment Protection Committee Guidelines)

The MEPC Guidelines emphasize EEDI as a mandatory technical measure setting minimum energy efficiency levels for new ships, while SEEMP serves as a flexible operational plan enabling all ships to improve energy efficiency through tailored management practices.

Technical File (EEDI Technical File)

The EEDI Technical File documents the ship's design-based energy efficiency metrics essential for regulatory compliance, while the SEEMP outlines operational strategies for continuous improvement in ship energy performance.

Operational Measures

Operational measures in SEEMP focus on real-time energy efficiency improvements and behavior optimization, while EEDI sets mandatory design-phase standards to reduce ship emissions through technical specifications.

Baseline Reference Lines

The EEDI establishes Baseline Reference Lines to quantify ship-specific CO2 emission targets based on ship type and size, while SEEMP uses these baselines to implement customized operational measures enhancing overall vessel energy efficiency.

Performance Monitoring Systems

EEDI measures a ship's design-phase carbon intensity to promote energy-efficient construction, while SEEMP implements operational Performance Monitoring Systems to optimize real-time energy usage and reduce emissions during voyages.

Voyage Optimization

EEDI quantifies a ship's design-phase carbon efficiency by setting emission limits, while SEEMP enables continuous Voyage Optimization through operational strategies to reduce fuel consumption and emissions during actual voyages.

EEDI (energy efficiency design index) vs SEEMP (ship energy efficiency management plan) Infographic

njnir.com

njnir.com