Azimuth thrusters offer 360-degree rotational capability, providing superior maneuverability and dynamic positioning for marine vessels. Z-Drive systems deliver powerful thrust through a vertically mounted gearbox with a horizontal input shaft, enabling efficient propulsion and steering in shallow waters. Both systems enhance vessel control but differ in mechanical configuration and optimal application scenarios.

Table of Comparison

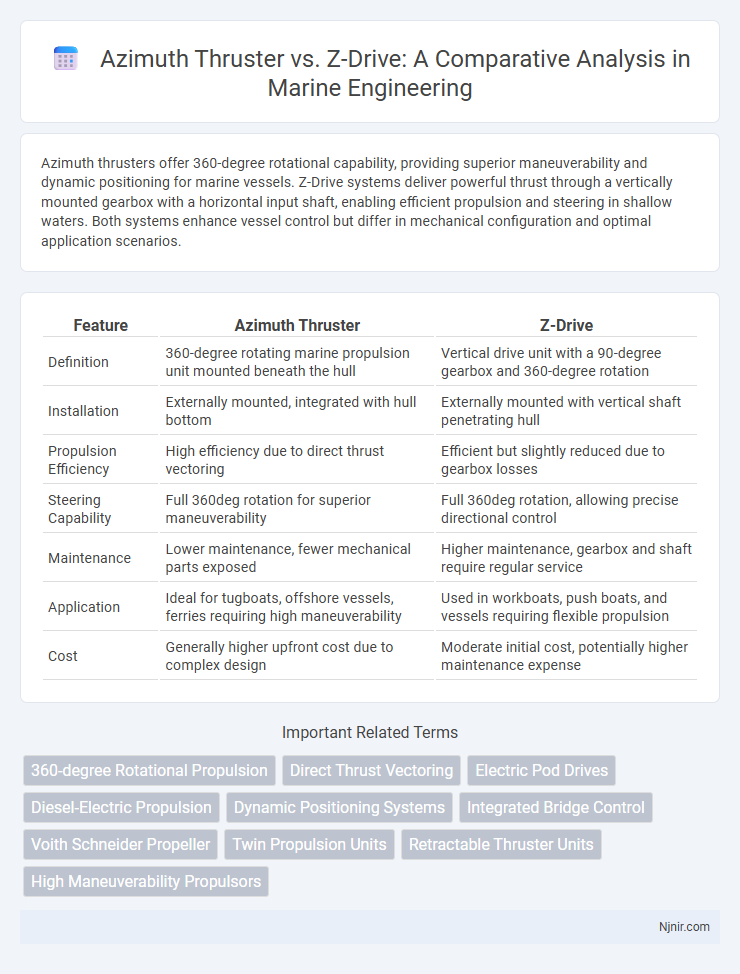

| Feature | Azimuth Thruster | Z-Drive |

|---|---|---|

| Definition | 360-degree rotating marine propulsion unit mounted beneath the hull | Vertical drive unit with a 90-degree gearbox and 360-degree rotation |

| Installation | Externally mounted, integrated with hull bottom | Externally mounted with vertical shaft penetrating hull |

| Propulsion Efficiency | High efficiency due to direct thrust vectoring | Efficient but slightly reduced due to gearbox losses |

| Steering Capability | Full 360deg rotation for superior maneuverability | Full 360deg rotation, allowing precise directional control |

| Maintenance | Lower maintenance, fewer mechanical parts exposed | Higher maintenance, gearbox and shaft require regular service |

| Application | Ideal for tugboats, offshore vessels, ferries requiring high maneuverability | Used in workboats, push boats, and vessels requiring flexible propulsion |

| Cost | Generally higher upfront cost due to complex design | Moderate initial cost, potentially higher maintenance expense |

Introduction to Marine Propulsion Systems

Marine propulsion systems include various technologies designed to optimize vessel maneuverability and efficiency, with Azimuth Thrusters and Z-Drives representing two advanced configurations. Azimuth Thrusters provide 360-degree rotation, enabling precise steering without rudders, improving fuel efficiency and reducing response time. Z-Drives feature a vertically oriented input shaft connected to a horizontally rotating propeller shaft via a Z-shaped gearbox, offering high maneuverability and compact design ideal for tugboats and offshore vessels.

Overview of Azimuth Thrusters

Azimuth thrusters are advanced marine propulsion units capable of rotating 360 degrees, providing exceptional maneuverability and precise vessel control. These thrusters integrate propeller and steering functions into a single compact system, often used in tugboats, offshore vessels, and ferries for dynamic positioning and efficient navigation. Their ability to deliver thrust in any horizontal direction significantly enhances vessel agility compared to traditional fixed or mechanically steered propellers.

Understanding the Z-Drive Mechanism

The Z-Drive mechanism features a vertical input shaft connected to a horizontal output shaft through a 90-degree gear arrangement, enabling thrust direction to rotate 360 degrees for superior maneuverability. Unlike fixed azimuth thrusters, Z-Drives offer enhanced vessel control by integrating steering and propulsion into a single unit mounted directly to the hull. This design reduces mechanical complexity and improves response time, making Z-Drives ideal for tugboats, ferries, and offshore supply vessels requiring precise handling.

Key Design Differences: Azimuth Thruster vs Z-Drive

Azimuth thrusters feature a vertical shaft connected directly to a horizontal propeller, allowing 360-degree rotation for precise maneuverability without additional mechanical linkages. Z-Drives incorporate a Z-shaped gear arrangement, transmitting power from a vertical input shaft to a horizontally oriented propeller shaft, enabling adjustable thrust direction with complex gearing. The simplified mechanical design of azimuth thrusters often results in lower maintenance compared to the intricate gearbox system found in Z-Drives.

Installation and Integration Considerations

Azimuth thrusters offer straightforward installation with hull integration requiring precise alignment to ensure optimal propulsion efficiency, often favored for retrofitting existing vessels due to their compact design. Z-drives demand more complex installation because their vertical input shaft and horizontal output shaft configuration necessitate reinforced structural support and intricate gearbox alignment, impacting ship design from the outset. Integration of azimuth thrusters simplifies maneuvering systems by combining steering and propulsion, whereas Z-drives require advanced control systems to synchronize dual-axis rotation and propulsion dynamics efficiently.

Maneuverability and Vessel Control

Azimuth thrusters provide 360-degree rotation, enabling superior maneuverability and precise vessel control in tight spaces, making them ideal for docking and dynamic positioning. Z-Drives also offer full rotational capability but feature a vertical leg with a horizontal propeller, which allows for easier integration with existing shaft lines and can improve thrust efficiency at higher speeds. Both systems enhance vessel handling, but azimuth thrusters excel in complex maneuvering scenarios, whereas Z-Drives balance maneuverability with efficiency in various marine applications.

Efficiency and Performance Comparison

Azimuth thrusters offer superior maneuverability by rotating 360 degrees, enabling precise vessel positioning and improved fuel efficiency in complex navigation scenarios. Z-Drives combine vertical and horizontal shafts to deliver high thrust and faster response times, enhancing overall propulsion performance for larger vessels. Efficiency in azimuth thrusters excels in dynamic positioning and shallow waters, whereas Z-Drives provide optimal power transfer and reduced vibration in high-speed operations.

Maintenance and Operational Costs

Azimuth thrusters typically offer lower maintenance costs due to fewer moving parts and simpler mechanical design compared to Z-Drives, which have complex articulation joints requiring more frequent inspections and lubrication. Operational costs are influenced by fuel efficiency and maneuverability, with azimuth thrusters generally providing better fuel economy in slow-speed operations, whereas Z-Drives excel in high-speed performance but may incur higher operational expenses due to increased wear. Selecting between the two systems depends on vessel type, operating conditions, and long-term cost analysis focused on maintenance intervals and fuel consumption rates.

Common Applications in Marine Vessels

Azimuth thrusters and Z-drives are extensively used in various marine vessels for enhanced maneuverability and propulsion efficiency. Azimuth thrusters are commonly found in tugboats, offshore supply vessels, and cruise ships, where precise directional control and dynamic positioning are critical. Z-drives are favored in ferries, dredgers, and fishing vessels due to their ability to provide 360-degree rotation and superior thrust control in complex marine operations.

Future Trends in Marine Thruster Technology

Azimuth Thruster technology is evolving with enhanced energy efficiency and integration of advanced control systems, promoting greater maneuverability and reduced emissions in marine vessels. Z-Drive thrusters are advancing toward compact designs with improved thrust vectoring capabilities, supporting the shift to hybrid and electric propulsion systems. Both technologies are increasingly incorporating AI-driven diagnostics and IoT connectivity for predictive maintenance and optimized performance in future marine applications.

360-degree Rotational Propulsion

Azimuth thrusters provide 360-degree rotational propulsion enabling precise maneuverability and efficient directional thrust control compared to traditional Z-Drive systems.

Direct Thrust Vectoring

Azimuth thrusters provide 360-degree direct thrust vectoring for precise maneuverability, whereas Z-Drives use a right-angle gearbox to redirect thrust but offer less immediate directional control.

Electric Pod Drives

Electric pod drives, including Azimuth thrusters and Z-Drives, differ mainly in their steering mechanisms, with Azimuth thrusters offering 360-degree rotation for enhanced maneuverability, while Z-Drives use a vertical drive shaft with horizontal propellers for efficient thrust direction changes.

Diesel-Electric Propulsion

Diesel-electric propulsion systems integrated with azimuth thrusters provide enhanced maneuverability and fuel efficiency compared to Z-drive configurations, particularly in dynamic positioning and variable speed applications.

Dynamic Positioning Systems

Azimuth thrusters provide 360-degree rotation enhancing maneuverability in dynamic positioning systems, while Z-drives combine vertical and horizontal thrust for precise station-keeping in complex marine environments.

Integrated Bridge Control

Integrated Bridge Control systems enhance operational efficiency and maneuverability in both Azimuth Thruster and Z-Drive configurations by providing centralized control and seamless coordination of propulsion and steering functions.

Voith Schneider Propeller

The Voith Schneider Propeller offers superior maneuverability and precise thrust vectoring compared to Azimuth Thrusters and Z-Drives, making it ideal for vessels requiring exceptional maneuvering capabilities in confined waters.

Twin Propulsion Units

Twin propulsion units in Azimuth Thrusters offer enhanced maneuverability and thrust vectoring compared to Z-Drive systems, which provide efficient directional control through articulated drive shafts.

Retractable Thruster Units

Retractable thruster units in azimuth thrusters offer enhanced maneuverability and reduced drag compared to fixed Z-drive systems, making them ideal for vessels requiring versatile propulsion and improved fuel efficiency.

High Maneuverability Propulsors

Azimuth thrusters provide high maneuverability by allowing 360-degree rotation for precise vessel control, whereas Z-Drives offer similar directional thrust with a robust gearbox configuration enhancing torque and efficiency in tight navigation scenarios.

Azimuth Thruster vs Z-Drive Infographic

njnir.com

njnir.com