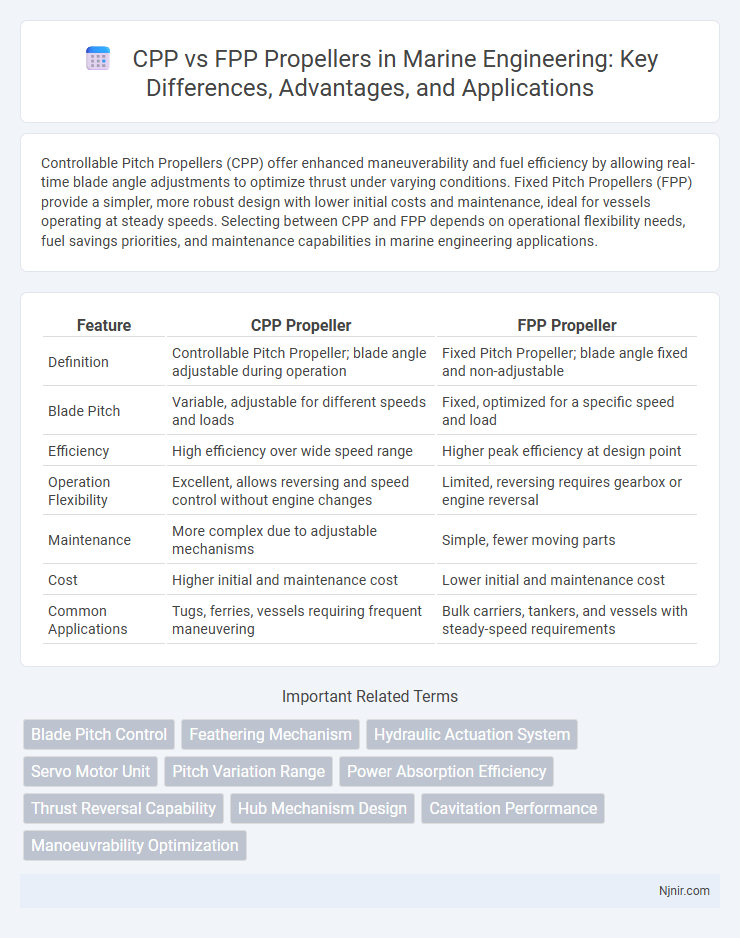

Controllable Pitch Propellers (CPP) offer enhanced maneuverability and fuel efficiency by allowing real-time blade angle adjustments to optimize thrust under varying conditions. Fixed Pitch Propellers (FPP) provide a simpler, more robust design with lower initial costs and maintenance, ideal for vessels operating at steady speeds. Selecting between CPP and FPP depends on operational flexibility needs, fuel savings priorities, and maintenance capabilities in marine engineering applications.

Table of Comparison

| Feature | CPP Propeller | FPP Propeller |

|---|---|---|

| Definition | Controllable Pitch Propeller; blade angle adjustable during operation | Fixed Pitch Propeller; blade angle fixed and non-adjustable |

| Blade Pitch | Variable, adjustable for different speeds and loads | Fixed, optimized for a specific speed and load |

| Efficiency | High efficiency over wide speed range | Higher peak efficiency at design point |

| Operation Flexibility | Excellent, allows reversing and speed control without engine changes | Limited, reversing requires gearbox or engine reversal |

| Maintenance | More complex due to adjustable mechanisms | Simple, fewer moving parts |

| Cost | Higher initial and maintenance cost | Lower initial and maintenance cost |

| Common Applications | Tugs, ferries, vessels requiring frequent maneuvering | Bulk carriers, tankers, and vessels with steady-speed requirements |

Introduction to CPP and FPP Propellers

Controllable Pitch Propellers (CPP) feature adjustable blade angles that optimize thrust and fuel efficiency across varying speeds and loads, making them ideal for vessels requiring frequent maneuvering and speed changes. Fixed Pitch Propellers (FPP) have blades set at a constant angle, delivering maximum efficiency at a specific engine speed but limiting operational flexibility. The choice between CPP and FPP impacts propulsion system responsiveness, fuel consumption, and maintenance depending on vessel type and operational profile.

Fundamental Design Differences

CPP (Controllable Pitch Propeller) features adjustable blade angles, allowing for optimized thrust and efficiency across various speeds and load conditions, while FPP (Fixed Pitch Propeller) has blades set at a fixed angle, providing a simple, robust design with consistent performance. The variable blade pitch in CPP enables reverse thrust and improved fuel efficiency in dynamic scenarios, whereas FPP relies on engine speed variation to control thrust direction and magnitude. CPP's hub includes a mechanism for pitch adjustment, increasing complexity and maintenance compared to the simpler, more durable FPP structure.

Efficiency and Performance Comparison

Controllable Pitch Propellers (CPP) offer superior efficiency across varying speeds and load conditions by adjusting blade angles to optimize thrust, reducing fuel consumption in dynamic operating environments. Fixed Pitch Propellers (FPP) provide peak efficiency only at a specific design point, often leading to diminished performance outside optimal conditions. CPP systems enhance maneuverability and acceleration, while FPP designs excel in simplicity and lower maintenance costs but sacrifice flexibility and overall operational efficiency.

Maneuverability and Operational Flexibility

CPP propellers offer superior maneuverability due to their ability to vary blade pitch continuously, allowing for immediate thrust reversal and precise speed control without changing engine speed. This feature enhances operational flexibility, making CPP ideal for vessels requiring frequent speed adjustments and dynamic positioning, such as tugboats and ferries. In contrast, FPP propellers have fixed blades that limit thrust modulation to engine speed changes and gearbox reversals, resulting in less responsive handling and reduced adaptability in complex navigation scenarios.

Maintenance and Reliability Considerations

Controllable Pitch Propellers (CPP) require more frequent and specialized maintenance due to their complex pitch-changing mechanisms, including hydraulic systems and moving blades, which can increase potential failure points. Fixed Pitch Propellers (FPP) offer higher reliability with simpler construction and fewer moving parts, resulting in lower maintenance costs and reduced downtime. However, CPPs provide operational flexibility that may justify the maintenance investment for vessels needing variable speed and load conditions.

Fuel Consumption and Environmental Impact

Controllable Pitch Propellers (CPP) offer superior fuel efficiency by allowing real-time blade angle adjustments, optimizing propulsion under varying operational conditions and leading to lower fuel consumption compared to Fixed Pitch Propellers (FPP). This enhanced fuel efficiency directly reduces greenhouse gas emissions and marine pollution, positioning CPPs as a more environmentally sustainable choice. Studies show that vessels equipped with CPP can achieve fuel savings of up to 10%, significantly mitigating the environmental impact of maritime operations.

Application Suitability in Marine Vessels

CPP propellers offer superior maneuverability and variable pitch control, making them ideal for vessels requiring frequent speed adjustments such as tugboats and ferries. FPP propellers are more efficient at constant speeds and suitable for large cargo ships and tankers operating in steady cruising modes. The choice between CPP and FPP depends on operational profiles where CPP enhances precision in dynamic environments while FPP maximizes fuel efficiency on long-haul voyages.

Cost Implications and Lifecycle Analysis

Controllable Pitch Propellers (CPP) typically involve higher initial costs due to their complex mechanisms and enhanced maneuverability, while Fixed Pitch Propellers (FPP) offer a more economical upfront investment with simpler construction. Lifecycle analysis reveals that CPPs can reduce fuel consumption and maintenance expenses over time, offsetting their higher acquisition cost through improved operational efficiency and adaptability to varying engine loads. FPPs, although cheaper initially, may incur greater long-term expenses linked to less flexible performance and more frequent overhaul requirements under variable operating conditions.

Technological Advancements in Propeller Systems

Controllable Pitch Propellers (CPP) incorporate advanced servo mechanisms and hydraulic actuators that enable precise blade angle adjustments, improving fuel efficiency and maneuverability compared to Fixed Pitch Propellers (FPP). Recent technological advancements include integration with automated control systems and real-time monitoring, allowing CPPs to optimize performance based on vessel speed and load conditions. These innovations reduce emissions and enhance propulsion efficiency, making CPPs a preferred choice in modern marine applications.

Choosing the Right Propeller for Marine Engineering Needs

Controllable Pitch Propellers (CPP) offer dynamic blade angle adjustment, optimizing fuel efficiency and maneuverability across varying operating conditions compared to Fixed Pitch Propellers (FPP), which have a fixed blade angle best suited for consistent speed operations. Marine engineers prioritize CPP for vessels requiring enhanced performance flexibility, such as tugs, ferries, and offshore supply ships, while FPP remains ideal for bulk carriers and tankers focused on straightforward, cost-effective propulsion. Selection depends on vessel type, operational profile, and fuel consumption goals, with CPP enabling better adaptability and FPP providing simplicity and lower initial costs.

Blade Pitch Control

CPP propellers feature adjustable blade pitch for real-time thrust optimization and fuel efficiency, whereas FPP propellers have fixed blade pitch requiring engine speed variation to control thrust.

Feathering Mechanism

CPP propellers feature a feathering mechanism that adjusts blade pitch to minimize drag and optimize performance, unlike FPP propellers which require manual or auxiliary systems for blade feathering.

Hydraulic Actuation System

The CPP propeller utilizes a sophisticated hydraulic actuation system for precise pitch control enabling enhanced maneuverability and fuel efficiency, whereas the FPP propeller relies on fixed blades without hydraulic adjustments, resulting in simpler but less flexible operation.

Servo Motor Unit

The CPP propeller with a servo motor unit offers precise pitch control and improved fuel efficiency compared to the fixed pitch FPP propeller, enhancing maneuverability and operational flexibility.

Pitch Variation Range

CPP propellers offer a broader pitch variation range, typically from -3deg to +35deg, enabling enhanced maneuverability and fuel efficiency compared to FPP propellers with fixed pitch angles around 20deg to 25deg.

Power Absorption Efficiency

CPP propellers provide superior power absorption efficiency compared to FPP propellers by allowing variable pitch adjustment that optimizes thrust and reduces energy loss under varying operating conditions.

Thrust Reversal Capability

CPP propellers provide superior thrust reversal capability by allowing variable pitch adjustments to quickly and efficiently alter thrust direction, unlike FPP propellers which rely on reversing engine rotation, resulting in slower and less precise thrust reversal.

Hub Mechanism Design

CPP propeller hub mechanism design incorporates adjustable pitch blades controlled by hydraulic or mechanical systems to optimize performance, while FPP propeller hub design features a fixed blade angle offering simpler construction but less operational flexibility.

Cavitation Performance

CPP propellers offer superior cavitation performance compared to FPP propellers due to adjustable blade pitch that optimizes flow conditions and reduces cavitation risk under varying operating speeds.

Manoeuvrability Optimization

CPP propellers enhance maneuverability optimization by allowing precise pitch control for rapid thrust adjustments, unlike fixed-pitch FPP propellers which lack flexibility in real-time maneuvering.

CPP propeller vs FPP propeller Infographic

njnir.com

njnir.com