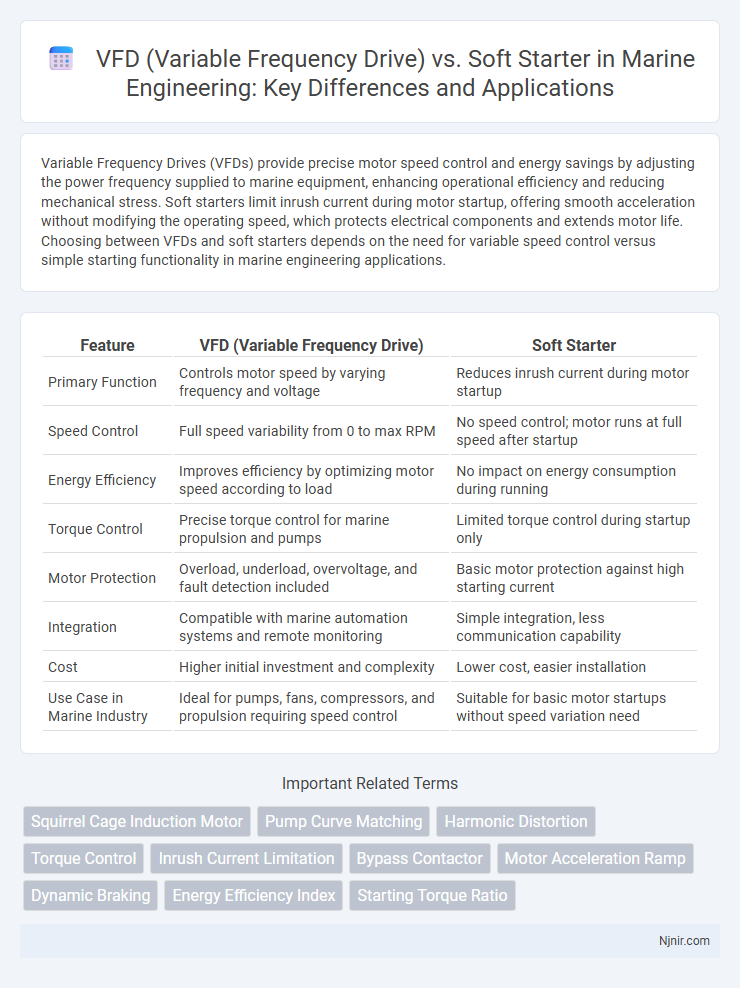

Variable Frequency Drives (VFDs) provide precise motor speed control and energy savings by adjusting the power frequency supplied to marine equipment, enhancing operational efficiency and reducing mechanical stress. Soft starters limit inrush current during motor startup, offering smooth acceleration without modifying the operating speed, which protects electrical components and extends motor life. Choosing between VFDs and soft starters depends on the need for variable speed control versus simple starting functionality in marine engineering applications.

Table of Comparison

| Feature | VFD (Variable Frequency Drive) | Soft Starter |

|---|---|---|

| Primary Function | Controls motor speed by varying frequency and voltage | Reduces inrush current during motor startup |

| Speed Control | Full speed variability from 0 to max RPM | No speed control; motor runs at full speed after startup |

| Energy Efficiency | Improves efficiency by optimizing motor speed according to load | No impact on energy consumption during running |

| Torque Control | Precise torque control for marine propulsion and pumps | Limited torque control during startup only |

| Motor Protection | Overload, underload, overvoltage, and fault detection included | Basic motor protection against high starting current |

| Integration | Compatible with marine automation systems and remote monitoring | Simple integration, less communication capability |

| Cost | Higher initial investment and complexity | Lower cost, easier installation |

| Use Case in Marine Industry | Ideal for pumps, fans, compressors, and propulsion requiring speed control | Suitable for basic motor startups without speed variation need |

Introduction to VFDs and Soft Starters in Marine Engineering

Variable Frequency Drives (VFDs) regulate motor speed and torque by adjusting the input frequency and voltage, improving energy efficiency and precise control in marine propulsion and auxiliary systems. Soft starters gradually ramp up motor voltage, reducing inrush current and mechanical stress during startup, ideal for pumps and compressors on ships. Both technologies enhance motor protection and operational reliability but serve different roles in marine engineering applications.

Key Operational Principles: VFDs vs Soft Starters

Variable Frequency Drives (VFDs) regulate motor speed and torque by varying the frequency and voltage supplied to the motor, enabling precise control over acceleration, deceleration, and operational speed. Soft starters limit inrush current and reduce mechanical stress during motor startup by gradually ramping up voltage without altering motor speed. VFDs offer continuous speed control and energy savings in variable load applications, whereas soft starters primarily provide smooth startup and protection without adjusting speed during operation.

Main Applications Onboard Ships

Variable Frequency Drives (VFDs) are widely used onboard ships for precise speed control of pumps, fans, and compressors, optimizing energy consumption and reducing mechanical stress. Soft starters are primarily employed to limit the inrush current during the startup of large motors like cargo pumps and winches, enhancing equipment longevity without speed modulation. Both technologies improve operational efficiency and equipment protection but are selected based on the need for speed variability or gentle motor starting.

Energy Efficiency Comparison

Variable frequency drives (VFDs) offer superior energy efficiency compared to soft starters by adjusting motor speed to match load requirements, thereby reducing power consumption significantly. Soft starters primarily limit inrush current during motor startup without regulating speed, resulting in constant energy use during operation. Implementing VFDs can lead to energy savings up to 30-50% in variable torque applications, enhancing operational efficiency and reducing electricity costs.

Impact on Motor Lifespan and Maintenance

Variable Frequency Drives (VFDs) extend motor lifespan by providing precise speed control and soft starting, reducing mechanical stress and electrical wear compared to conventional starting methods. Soft starters limit inrush current and torque during motor startup, minimizing mechanical stress but lack continuous speed control, resulting in moderate impact on motor longevity. Maintenance requirements for VFD-equipped motors often involve monitoring electronic components and cooling systems, whereas soft starters typically require less complex upkeep focused on contactors and controlling devices.

Start-Up Performance and Torque Control

Variable frequency drives (VFDs) provide precise start-up performance by controlling motor speed through adjustable frequency, allowing smooth acceleration and optimal torque management during startup. Soft starters reduce inrush current by gradually ramping voltage but lack fine torque control and speed variation capabilities, leading to less efficient handling of load dynamics. VFDs enhance motor protection and energy efficiency by maintaining consistent torque, whereas soft starters primarily minimize electrical stress without dynamic torque adjustment.

Space, Weight, and Installation Requirements

Variable frequency drives (VFDs) generally require more space and weight due to their complex electronic components and cooling systems, whereas soft starters are more compact and lightweight, making them suitable for tighter installation environments. VFDs demand careful installation with adequate ventilation and shielding to prevent electromagnetic interference, while soft starters have simpler wiring and minimal HVAC requirements, reducing installation complexity. Choosing between a VFD and a soft starter hinge on available installation space, weight constraints, and the level of motor control needed.

Harmonics and Power Quality Considerations

Variable Frequency Drives (VFDs) generate higher harmonic distortion due to their pulse-width modulation operation, which can impact power quality and require harmonic filters or mitigation techniques. Soft starters produce lower harmonics as they gradually ramp up voltage and current, reducing electrical stress without significantly affecting power quality. Selecting between VFDs and soft starters depends on the application's need for speed control versus the priority for maintaining low harmonic distortion and optimal power factor.

Cost Analysis: Initial Investment vs Long-Term Savings

Variable Frequency Drives (VFDs) typically require a higher initial investment compared to soft starters due to their complex electronics and advanced control capabilities. Soft starters have lower upfront costs but lack energy savings during operation, leading to higher long-term energy expenses. VFDs optimize motor speed and reduce energy consumption, resulting in significant long-term savings that can offset their initial costs over time.

Choosing the Right Solution for Marine Applications

Selecting between a Variable Frequency Drive (VFD) and a soft starter for marine applications depends on specific operational requirements such as energy efficiency, torque control, and system complexity. VFDs offer precise speed control and energy savings by adjusting motor frequency, essential for variable load conditions in propulsion and pump systems aboard ships. Soft starters, while simpler and cost-effective, primarily reduce inrush current during startup, making them suitable for applications with fixed-speed motors where smooth acceleration is needed without the demand for speed variation.

Squirrel Cage Induction Motor

Variable Frequency Drives (VFDs) optimize Squirrel Cage Induction Motor performance by precisely controlling speed and torque, while soft starters primarily reduce inrush current during motor startup without adjustable speed control.

Pump Curve Matching

Variable frequency drives provide precise pump curve matching by continuously adjusting motor speed to optimize flow and pressure, whereas soft starters offer limited control by only reducing initial starting current without dynamically aligning the pump performance to system requirements.

Harmonic Distortion

Variable Frequency Drives (VFDs) typically generate higher harmonic distortion compared to soft starters, necessitating harmonic filters to maintain power quality in electrical systems.

Torque Control

Variable frequency drives provide precise torque control by continuously adjusting motor speed and frequency, whereas soft starters only limit starting torque through voltage ramp-up without speed regulation.

Inrush Current Limitation

Variable frequency drives (VFDs provide precise inrush current limitation by gradually ramping motor voltage and frequency, significantly reducing mechanical stress and electrical surges compared to soft starters that only limit initial current without continuous control during startup.

Bypass Contactor

A VFD integrates a bypass contactor to enable motor operation at full line voltage by bypassing the drive, enhancing efficiency and reducing wear compared to soft starters that typically do not use bypass contactors.

Motor Acceleration Ramp

Variable Frequency Drives (VFDs) provide precise motor acceleration ramp control by adjusting frequency and voltage, enabling smooth speed transitions and energy savings, while soft starters offer fixed ramp time with limited speed regulation primarily for reduced inrush current during startup.

Dynamic Braking

Dynamic braking in VFDs provides efficient energy dissipation and controlled deceleration, whereas soft starters lack dynamic braking capabilities and primarily reduce inrush current during startup.

Energy Efficiency Index

Variable frequency drives (VFDs) improve energy efficiency by adjusting motor speed to load demand, resulting in a lower Energy Efficiency Index compared to soft starters that only reduce inrush current without optimizing operational energy use.

Starting Torque Ratio

Variable frequency drives provide a starting torque ratio close to 1 by controlling motor speed and frequency, whereas soft starters typically offer a reduced starting torque ratio around 0.5 to 0.7 by gradually ramping up voltage.

VFD (variable frequency drive) vs soft starter Infographic

njnir.com

njnir.com