Scrubbers and Selective Catalytic Reduction (SCR) systems are critical technologies in marine engineering for reducing sulfur oxides (SOx) and nitrogen oxides (NOx) emissions respectively, ensuring compliance with IMO emission regulations. Scrubbers use seawater or chemical solutions to wash SOx from exhaust gases, while SCR injects a urea-based reagent into the exhaust stream to convert NOx into harmless nitrogen and water through catalytic reactions. Optimizing these systems enhances fuel efficiency, lowers environmental impact, and supports sustainable marine operations.

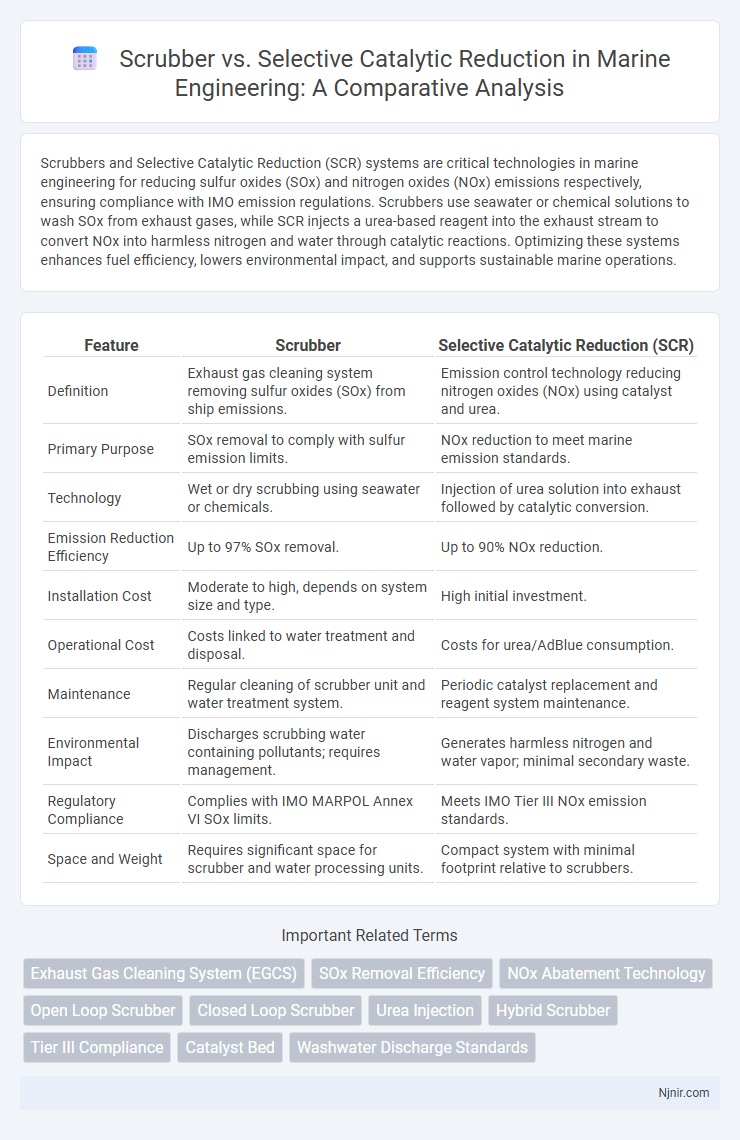

Table of Comparison

| Feature | Scrubber | Selective Catalytic Reduction (SCR) |

|---|---|---|

| Definition | Exhaust gas cleaning system removing sulfur oxides (SOx) from ship emissions. | Emission control technology reducing nitrogen oxides (NOx) using catalyst and urea. |

| Primary Purpose | SOx removal to comply with sulfur emission limits. | NOx reduction to meet marine emission standards. |

| Technology | Wet or dry scrubbing using seawater or chemicals. | Injection of urea solution into exhaust followed by catalytic conversion. |

| Emission Reduction Efficiency | Up to 97% SOx removal. | Up to 90% NOx reduction. |

| Installation Cost | Moderate to high, depends on system size and type. | High initial investment. |

| Operational Cost | Costs linked to water treatment and disposal. | Costs for urea/AdBlue consumption. |

| Maintenance | Regular cleaning of scrubber unit and water treatment system. | Periodic catalyst replacement and reagent system maintenance. |

| Environmental Impact | Discharges scrubbing water containing pollutants; requires management. | Generates harmless nitrogen and water vapor; minimal secondary waste. |

| Regulatory Compliance | Complies with IMO MARPOL Annex VI SOx limits. | Meets IMO Tier III NOx emission standards. |

| Space and Weight | Requires significant space for scrubber and water processing units. | Compact system with minimal footprint relative to scrubbers. |

Introduction to Marine Emission Control Technologies

Marine emission control technologies include scrubbers and selective catalytic reduction (SCR) systems, both designed to reduce harmful pollutants from ship exhaust. Scrubbers primarily target sulfur oxides (SOx) by using seawater or freshwater to remove sulfur compounds, while SCR systems reduce nitrogen oxides (NOx) emissions through catalytic reactions involving ammonia or urea. Integrating these technologies helps comply with International Maritime Organization (IMO) regulations, improving air quality and minimizing the environmental impact of maritime operations.

Understanding Marine Scrubbers: Types and Functions

Marine scrubbers are exhaust gas cleaning systems designed to remove sulfur oxides (SOx) from ship emissions, primarily using open-loop, closed-loop, or hybrid systems, each differing by the water source and treatment method. Selective catalytic reduction (SCR) systems target nitrogen oxides (NOx) by injecting a urea-based reagent into the exhaust stream, converting NOx into nitrogen and water through a catalytic reaction. Understanding the distinct operational principles and pollutant targets of scrubbers and SCR systems is essential for optimizing emission control and complying with maritime environmental regulations.

Overview of Selective Catalytic Reduction (SCR) Systems

Selective Catalytic Reduction (SCR) systems reduce nitrogen oxides (NOx) emissions by injecting a reductant, typically ammonia or urea, into the exhaust stream where it reacts with NOx over a catalyst, converting pollutants into harmless nitrogen and water vapor. SCR technology is widely used in power plants, industrial boilers, and diesel engines to meet stringent environmental regulations by achieving NOx reduction efficiencies of up to 90%. These systems offer advantages over scrubbers by specifically targeting NOx without generating secondary waste streams, making them a preferred solution for air pollution control in combustion processes.

Regulatory Framework: IMO MARPOL Annex VI Compliance

Scrubbers and Selective Catalytic Reduction (SCR) systems both play critical roles in meeting IMO MARPOL Annex VI regulations aimed at reducing sulfur oxides (SOx) and nitrogen oxides (NOx) emissions from ships. Scrubbers enable compliance by removing SOx from exhaust gases, allowing continued use of higher sulfur fuels, whereas SCR systems specifically target NOx reduction through chemical reactions facilitated by catalysts. Shipping operators often choose between these technologies based on emission control area (ECA) requirements, fuel costs, and operational factors under the regulatory framework mandated by IMO for global air pollution control.

Emissions Reduction Performance: Scrubber vs SCR

Scrubbers effectively reduce sulfur oxides (SOx) emissions by up to 95%, making them ideal for controlling acid rain-causing pollutants in marine and industrial applications. Selective Catalytic Reduction (SCR) systems focus primarily on nitrogen oxides (NOx) reduction, achieving up to 90% efficiency by converting NOx into nitrogen and water through ammonia injection and catalysis. Both technologies complement each other in emissions control strategies, with scrubbers targeting SOx and SCR systems optimizing NOx reduction for comprehensive air quality improvement.

Installation and Integration Challenges

Scrubbers require extensive space and complex ductwork for installation, often posing challenges in retrofit scenarios due to their size and weight. Selective Catalytic Reduction (SCR) systems demand precise integration with existing engine control systems and require careful placement of catalysts and ammonia injection points to ensure optimal performance. Both technologies involve significant downtime during installation and require specialized expertise to align with regulatory standards and operational parameters.

Operational Costs and Maintenance Requirements

Scrubbers generally incur higher operational costs due to the continuous consumption of water, chemicals, and energy needed for scrubbing processes, alongside frequent sludge disposal requirements. Selective catalytic reduction (SCR) systems demand significant upfront investment with moderate operational costs, primarily from ammonia or urea reagent supply and periodic catalyst replacement every 3-5 years. Maintenance for scrubbers involves frequent cleaning and component inspection to prevent corrosion and scaling, whereas SCR systems require catalyst monitoring and occasional catalyst regeneration or replacement to maintain NOx reduction efficiency.

Environmental Impact and Byproduct Management

Scrubbers effectively reduce sulfur dioxide (SO2) emissions by using chemical reactions with alkaline substances, resulting in byproducts such as gypsum, which can be managed or repurposed. Selective Catalytic Reduction (SCR) systems target nitrogen oxides (NOx) reduction by injecting ammonia or urea into exhaust gases, producing nitrogen and water as primary byproducts that require careful control to prevent ammonia slip. Both technologies significantly lower harmful emissions, but SCR offers superior NOx reduction efficiency with minimal hazardous byproducts compared to scrubbers.

Retrofit vs Newbuild Applications in Marine Vessels

Scrubber technology enables retrofit applications on existing marine vessels by removing sulfur oxides (SOx) from exhaust gases, utilizing seawater or chemical washing processes without altering the engine system. Selective Catalytic Reduction (SCR) systems are more suited for newbuild vessels due to their integration with the engine design and the requirement for precise dosing of urea-based reductants to reduce nitrogen oxides (NOx). Retrofit SCR installations often face challenges with space, weight, and modifications to the exhaust system, whereas scrubbers offer a simpler retrofit solution meeting IMO 2020 sulfur emission limits.

Future Trends in Marine Emissions Control Technologies

Scrubber and Selective Catalytic Reduction (SCR) technologies are evolving rapidly to meet stringent IMO 2020 sulfur limits and upcoming NOx emission standards in the maritime sector. Future trends emphasize hybrid systems combining scrubbers with SCR to achieve comprehensive emissions control, optimizing fuel efficiency and reducing operational costs. Advanced materials and AI-driven monitoring are expected to enhance performance, making these technologies critical in transitioning to greener shipping.

Exhaust Gas Cleaning System (EGCS)

Scrubbers use liquid chemicals to remove sulfur oxides from exhaust gases, while Selective Catalytic Reduction (SCR) systems use ammonia or urea-based catalysts to reduce nitrogen oxides, both serving as crucial components of Exhaust Gas Cleaning Systems (EGCS) to meet stringent maritime emission regulations.

SOx Removal Efficiency

Selective catalytic reduction achieves higher SOx removal efficiency, often exceeding 90%, compared to traditional scrubbers which typically remove 70-85% of SOx emissions.

NOx Abatement Technology

Selective catalytic reduction (SCR) achieves higher NOx abatement efficiency by chemically converting NOx into nitrogen and water using a catalyst, whereas scrubbers primarily rely on physical removal and absorbent chemicals with generally lower NOx reduction performance.

Open Loop Scrubber

Open Loop Scrubbers use seawater to remove sulfur oxides from ship exhaust gases without chemical reagents, contrasting with Selective Catalytic Reduction systems that reduce nitrogen oxides via ammonia injection and catalytic converters.

Closed Loop Scrubber

Closed Loop Scrubbers efficiently remove sulfur oxides from ship exhaust by recycling washwater, contrasting with Selective Catalytic Reduction systems that reduce nitrogen oxides through chemical injection.

Urea Injection

Selective catalytic reduction uses urea injection to convert nitrogen oxides into nitrogen and water, whereas scrubbers remove pollutants by washing exhaust gases without urea.

Hybrid Scrubber

Hybrid scrubbers combine the benefits of traditional wet scrubbers and Selective Catalytic Reduction (SCR) systems to efficiently reduce sulfur oxides (SOx) and nitrogen oxides (NOx) emissions in marine and industrial applications.

Tier III Compliance

Selective catalytic reduction (SCR) technology achieves Tier III compliance by reducing nitrogen oxide (NOx) emissions up to 90%, whereas scrubbers primarily control sulfur oxide (SOx) emissions and do not directly address NOx limits required for Tier III standards.

Catalyst Bed

Selective catalytic reduction uses a catalyst bed composed of materials like vanadium or zeolites to convert NOx into nitrogen and water, whereas scrubbers primarily rely on liquid-phase chemical reactions without a catalyst bed.

Washwater Discharge Standards

Selective catalytic reduction systems produce lower washwater discharge volumes and contaminants compared to scrubbers, facilitating easier compliance with stringent environmental discharge standards.

Scrubber vs Selective catalytic reduction Infographic

njnir.com

njnir.com