Oil-water separators utilize gravity to separate oil from water by allowing oil droplets to rise and be skimmed off, making them ideal for large-scale marine wastewater treatment. Oily water filters, on the other hand, use mechanical filtration and adsorbent materials to remove smaller oil particles and emulsified oils, providing finer purification for discharge compliance. Selecting between these technologies depends on the specific contamination levels and regulatory requirements in marine engineering applications.

Table of Comparison

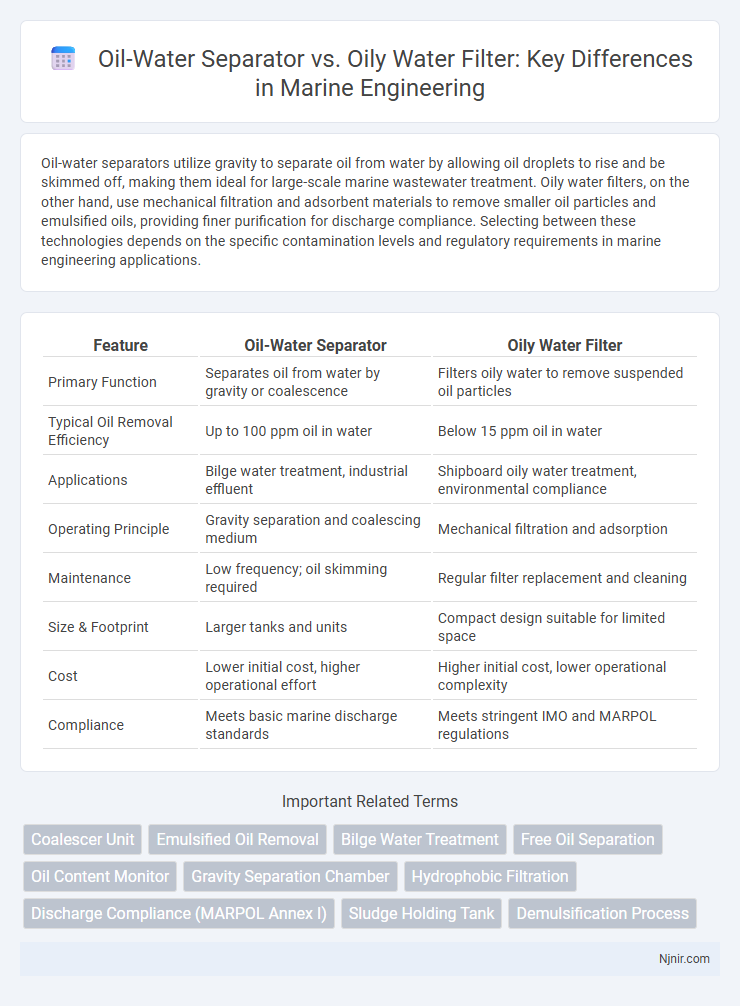

| Feature | Oil-Water Separator | Oily Water Filter |

|---|---|---|

| Primary Function | Separates oil from water by gravity or coalescence | Filters oily water to remove suspended oil particles |

| Typical Oil Removal Efficiency | Up to 100 ppm oil in water | Below 15 ppm oil in water |

| Applications | Bilge water treatment, industrial effluent | Shipboard oily water treatment, environmental compliance |

| Operating Principle | Gravity separation and coalescing medium | Mechanical filtration and adsorption |

| Maintenance | Low frequency; oil skimming required | Regular filter replacement and cleaning |

| Size & Footprint | Larger tanks and units | Compact design suitable for limited space |

| Cost | Lower initial cost, higher operational effort | Higher initial cost, lower operational complexity |

| Compliance | Meets basic marine discharge standards | Meets stringent IMO and MARPOL regulations |

Introduction to Marine Oil-Water Separation Technologies

Marine oil-water separation technologies are essential for protecting marine ecosystems by efficiently removing hydrocarbons from bilge water. Oil-water separators utilize gravity and coalescing filters to separate oil droplets based on density differences, complying with regulations such as MARPOL Annex I. In contrast, oily water filters employ advanced filtration media and membranes to capture smaller oil particles, offering enhanced treatment for complex waste streams on vessels.

Overview of Oil-Water Separators

Oil-water separators are mechanical devices designed to separate oil and suspended solids from wastewater, commonly used in industries such as petrochemical, marine, and manufacturing. These systems rely on gravity separation, coalescing plates, or centrifugal force to efficiently remove free-phase oil before discharge or further treatment. Compared to oily water filters, oil-water separators handle larger volumes and are optimized for continuous operation with varying oil concentrations.

Understanding Oily Water Filters

Oily water filters are designed to remove fine oil droplets and suspended hydrocarbons from water, providing a higher level of purification compared to oil-water separators, which primarily separate oil from water through gravity and coalescence. These filters use advanced media or membranes to trap emulsified oils, ensuring compliance with environmental discharge regulations and protecting marine ecosystems. Understanding the filtration mechanisms and maintenance requirements of oily water filters is essential for industries handling wastewater containing oil contaminants.

Key Differences: Oil-Water Separator vs Oily Water Filter

Oil-water separators primarily rely on gravity and density differences to separate oil from water, effectively handling larger volumes with visible oil layers, while oily water filters utilize filtration media or membranes to remove smaller oil droplets and emulsified oils. Oil-water separators are typically used in industrial and marine applications for bulk oil removal, whereas oily water filters are suited for polishing treated water to meet stringent discharge standards. The main difference lies in their separation mechanism and efficiency in treating different oil contamination forms in water.

Operational Principles and Mechanisms

Oil-water separators operate on the principle of density difference, allowing oil droplets to float to the surface while heavier water settles below, often enhanced by gravity, coalescing plates, or centrifugal force. Oily water filters utilize physical filtration media and sometimes adsorption materials to trap oil particles and emulsified contaminants, effectively reducing the oil content to meet environmental discharge standards. Both systems aim for phase separation but differ in mechanisms: separators rely on buoyancy and coalescence, whereas filters depend on mechanical straining and chemical affinity.

Efficiency in Contaminant Removal

Oil-water separators typically achieve higher efficiency in removing free-phase hydrocarbons and large oil droplets from wastewater due to gravity separation principles, often reaching removal rates above 90%. Oily water filters excel in eliminating emulsified oils and smaller particulate contaminants through mechanical filtration and coalescing media, providing enhanced removal of microscopic oil droplets and suspended solids. Combining both technologies can optimize overall contaminant removal efficiency, addressing a broader range of oil particle sizes and improving water quality compliance.

Installation and Maintenance Considerations

Oil-water separators typically require larger installation spaces and more complex plumbing compared to oily water filters, making initial setup more demanding in industrial settings. Maintenance for oil-water separators involves routine inspection of separation chambers and periodic removal of accumulated oil, which can be labor-intensive and necessitates specialized equipment. In contrast, oily water filters generally feature compact designs with simpler installation and easier maintenance processes, such as filter cartridge replacement and less frequent cleaning, benefiting smaller-scale or mobile applications.

Compliance with Marine Environmental Regulations

Oil-water separators and oily water filters are essential for compliance with MARPOL Annex I regulations, which limit oil discharge into marine environments. Oil-water separators primarily remove free-phase oil from bilge water, ensuring oil content remains below 15 ppm before discharge, meeting IMO standards. Oily water filters enhance compliance by providing an additional filtration stage to capture finer oil droplets and contaminants, thereby reducing pollution risks and ensuring adherence to stringent environmental laws.

Cost Analysis: Initial and Lifecycle Expenses

Oil-water separators typically have higher initial costs due to larger equipment size and complex installation requirements compared to oily water filters, which are more compact and cost-effective upfront. Lifecycle expenses for oil-water separators often include higher maintenance and operational costs because of periodic cleaning and sludge disposal, whereas oily water filters generally incur lower maintenance costs and easier filter replacements. When evaluating total cost of ownership, oily water filters may offer more economical solutions for smaller-scale or less contaminated wastewater streams, while oil-water separators justify their investment in applications with higher throughput and heavier oil contamination.

Choosing the Right Solution for Marine Applications

Selecting the right solution for marine oil-water management depends on factors like contamination levels, flow rate, and regulatory compliance. Oil-water separators excel in handling large volumes with gravity-based separation, ideal for bilge water with higher oil content. Oily water filters provide finer filtration for lower oil concentrations, ensuring compliance with strict maritime discharge standards and protecting sensitive marine environments.

Coalescer Unit

The Coalescer Unit in oil-water separators enhances the separation efficiency by agglomerating fine oil droplets into larger ones, surpassing the performance of standard oily water filters in treating emulsified wastewater.

Emulsified Oil Removal

Oil-water separators primarily remove free-phase oil, while oily water filters are designed to effectively eliminate emulsified oil particles for enhanced water purification.

Bilge Water Treatment

Oil-water separators efficiently remove free oil from bilge water by gravity separation, while oily water filters use advanced filtration media to target smaller oil droplets and suspended solids, ensuring compliance with maritime bilge water discharge regulations.

Free Oil Separation

Free oil separation in oil-water separators efficiently removes bulk oil from wastewater, whereas oily water filters target smaller dispersed oil droplets for enhanced purification.

Oil Content Monitor

Oil Content Monitors in oil-water separators provide real-time, precise measurement of oil concentration to ensure regulatory compliance, while oily water filters primarily focus on removing oil particles without continuous monitoring.

Gravity Separation Chamber

The Gravity Separation Chamber in oil-water separators utilizes density differences to efficiently separate oil from water, whereas oily water filters rely on physical filtration methods without emphasizing gravity-based separation.

Hydrophobic Filtration

Hydrophobic filtration in oily water filters selectively repels water while capturing oil contaminants, offering higher efficiency and reduced maintenance compared to conventional oil-water separators.

Discharge Compliance (MARPOL Annex I)

Oil-water separators achieve MARPOL Annex I discharge compliance by efficiently separating oil from bilge water before discharge, while oily water filters provide additional polishing to meet stricter oil content limits below 15 ppm.

Sludge Holding Tank

Oil-water separators feature a Sludge Holding Tank that efficiently collects and stores accumulated sludge, whereas oily water filters primarily focus on filtration without dedicated sludge storage capacity.

Demulsification Process

The oil-water separator employs a demulsification process that breaks down oil-water emulsions using coalescing agents or electrostatic fields, whereas an oily water filter primarily relies on mechanical filtration to remove oil droplets without altering the emulsion state.

oil-water separator vs oily water filter Infographic

njnir.com

njnir.com