Podded propulsion systems offer improved maneuverability and higher efficiency compared to traditional shaftline setups by integrating the electric motor directly into a steerable pod beneath the hull. Unlike conventional shaftline systems that rely on long shafts and multiple components, podded drives reduce vibration and noise, enhancing onboard comfort. Maintenance is streamlined as pod units can be removed or repaired independently without dry-docking the entire vessel, making them a cost-effective solution for modern marine engineering.

Table of Comparison

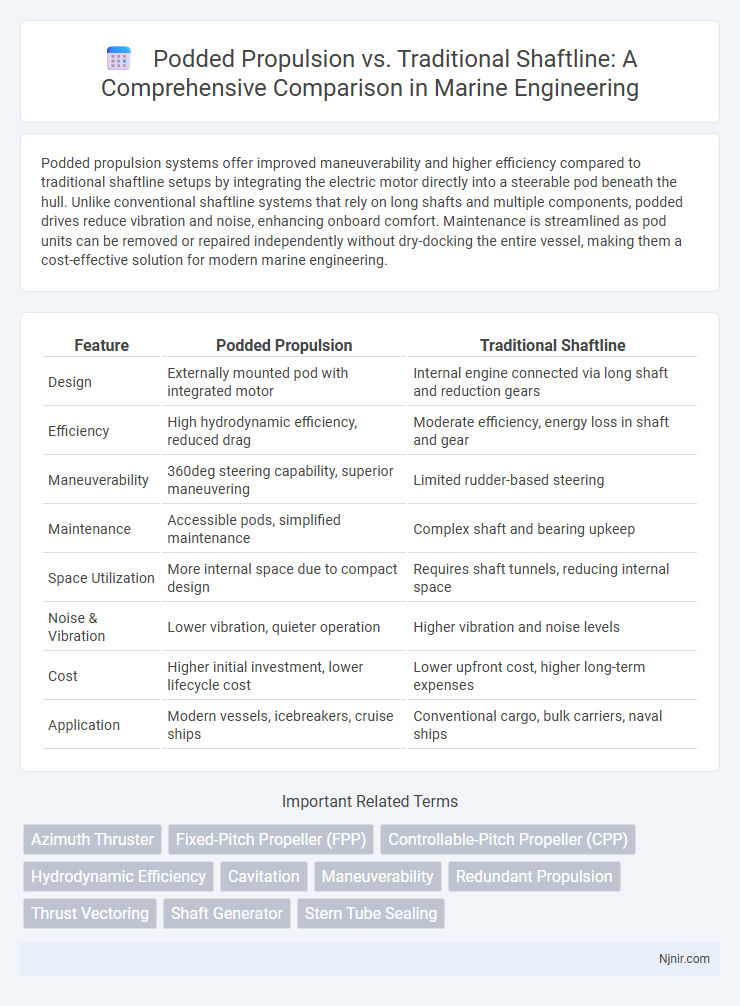

| Feature | Podded Propulsion | Traditional Shaftline |

|---|---|---|

| Design | Externally mounted pod with integrated motor | Internal engine connected via long shaft and reduction gears |

| Efficiency | High hydrodynamic efficiency, reduced drag | Moderate efficiency, energy loss in shaft and gear |

| Maneuverability | 360deg steering capability, superior maneuvering | Limited rudder-based steering |

| Maintenance | Accessible pods, simplified maintenance | Complex shaft and bearing upkeep |

| Space Utilization | More internal space due to compact design | Requires shaft tunnels, reducing internal space |

| Noise & Vibration | Lower vibration, quieter operation | Higher vibration and noise levels |

| Cost | Higher initial investment, lower lifecycle cost | Lower upfront cost, higher long-term expenses |

| Application | Modern vessels, icebreakers, cruise ships | Conventional cargo, bulk carriers, naval ships |

Introduction to Podded Propulsion and Traditional Shaftline

Podded propulsion systems integrate electric motors directly into steerable pods, enhancing maneuverability and fuel efficiency compared to traditional shaftline arrangements. Traditional shaftline propulsion transmits power from engines to propellers via long shafts, couplings, and bearings, which can result in higher mechanical losses and limited steering capabilities. The compact design of podded units reduces drag and vibration, offering improved vessel performance and operational flexibility.

Design Principles of Podded Propulsion Systems

Podded propulsion systems integrate electric motors directly into steerable pods, eliminating the need for long shaftlines and reducing mechanical complexity. The design emphasizes compactness, enhanced maneuverability, and improved hydrodynamic efficiency by positioning propellers outside the hull. These systems allow for precise thrust vectoring and lower vibration levels, optimizing fuel consumption and operational flexibility compared to traditional shaftline arrangements.

Traditional Shaftline Configuration Explained

Traditional shaftline configurations consist of an engine connected to a propeller shaft that transmits power through bearings and couplings to a single or dual fixed propeller. This design typically involves a long shaft running underwater, supported by struts, which can lead to increased vibration, frictional losses, and maintenance complexity. Despite these challenges, traditional shaftlines remain widely used for their mechanical simplicity, proven reliability, and cost-effective manufacturing for large vessels.

Efficiency Comparison: Podded vs Shaftline

Podded propulsion systems offer higher hydrodynamic efficiency by eliminating shaftline resistance and optimizing thrust alignment, resulting in fuel savings of up to 10-15% compared to traditional shaftline setups. Their ability to rotate independently enhances maneuverability, reducing energy loss during course adjustments, which contributes to overall operational efficiency. Conversely, traditional shaftlines incur energy losses from mechanical friction and fixed propeller angles, leading to lower propulsion efficiency in diverse operating conditions.

Maneuverability and Handling Performance

Podded propulsion systems enhance maneuverability by providing 360-degree thrust vectoring, enabling precise control and tighter turning radii compared to traditional shaftline configurations that rely on fixed rudders and propellers. This direct thrust direction capability improves handling performance in confined waters and during docking procedures, reducing reaction time and increasing vessel responsiveness. Traditional shaftline setups often face limitations in agility, especially at low speeds, where podded drives excel by allowing independent and variable thrust adjustments.

Installation and Maintenance Requirements

Podded propulsion systems offer simplified installation by integrating electric motors directly into the pods, eliminating the need for lengthy shaftlines and reducing hull modifications compared to traditional shaftline setups. Maintenance is streamlined as podded units allow easier access for servicing without dry-docking, unlike shaftline systems which require disassembly of shafts, bearings, and coupling components. This results in reduced downtime and lower labor costs, making podded propulsion advantageous in both initial installation and ongoing maintenance.

Impact on Vessel Space and Layout

Podded propulsion systems eliminate the need for long shafts and gearboxes, freeing up valuable internal space in the vessel's hull, which can be repurposed for additional cargo, passenger areas, or machinery. Traditional shaftline configurations require extensive tunnel compartments and alignment space, restricting design flexibility and increasing hull volume dedicated to propulsion machinery. By optimizing vessel layout with podded propulsion, naval architects can enhance hydrodynamic efficiency and maximize usable onboard volume, improving overall vessel performance and operational capability.

Operational Cost Analysis

Podded propulsion systems significantly reduce operational costs by enhancing fuel efficiency and lowering maintenance requirements compared to traditional shaftline setups. These systems eliminate long shaftlines and bulky gearboxes, resulting in fewer mechanical failures and decreased downtime. Data from maritime studies indicate that vessels equipped with podded propulsion can achieve fuel savings of up to 10-15%, translating into substantial annual cost reductions for commercial operators.

Environmental Considerations and Emissions

Podded propulsion systems enhance energy efficiency by reducing hydrodynamic drag and enabling precise thrust vectoring, leading to lower fuel consumption and decreased greenhouse gas emissions compared to traditional shaftline setups. These systems often utilize electric motors directly coupled to propellers, eliminating the need for long shaftlines and improving overall vessel maneuverability, which contributes to optimized engine loads and reduced pollutant output. Additionally, the compact design of podded propulsion supports integration with alternative fuels and hybrid technologies, further minimizing sulfur oxides (SOx), nitrogen oxides (NOx), and particulate matter emissions in compliance with stringent environmental regulations.

Future Trends in Marine Propulsion Technologies

Podded propulsion systems offer superior maneuverability and fuel efficiency compared to traditional shaftline configurations, driving their increased adoption in modern vessels. Advances in electric motor technology and integration with hybrid power systems are accelerating the shift toward podded propulsion, enabling lower emissions and enhanced vessel performance. Future trends emphasize digital twin simulations and AI-driven predictive maintenance to optimize podded propulsion efficiency and reliability in maritime operations.

Azimuth Thruster

Azimuth thrusters provide superior maneuverability and fuel efficiency compared to traditional shaftline systems by enabling 360-degree rotation and direct thrust vectoring.

Fixed-Pitch Propeller (FPP)

Podded propulsion with Fixed-Pitch Propellers (FPP) enhances maneuverability and efficiency by eliminating traditional shaftline losses and enabling direct thrust vectoring.

Controllable-Pitch Propeller (CPP)

Podded propulsion systems with Controllable-Pitch Propellers (CPP) offer enhanced maneuverability and fuel efficiency compared to traditional shaftline CPP configurations by allowing precise blade angle adjustments and eliminating mechanical shaft losses.

Hydrodynamic Efficiency

Podded propulsion systems enhance hydrodynamic efficiency by minimizing drag and improving thrust alignment compared to traditional shaftline configurations, resulting in lower fuel consumption and increased vessel maneuverability.

Cavitation

Podded propulsion significantly reduces cavitation compared to traditional shaftline systems by optimizing thrust alignment and minimizing propeller-induced pressure fluctuations.

Maneuverability

Podded propulsion systems provide superior maneuverability compared to traditional shaftline systems by enabling 360-degree rotation and precise thrust vectoring for enhanced vessel control.

Redundant Propulsion

Podded propulsion systems enhance maritime safety by providing redundant propulsion units that continue operation independently, reducing reliance on a single traditional shaftline and minimizing the risk of total propulsion failure.

Thrust Vectoring

Podded propulsion systems enable precise thrust vectoring by independently rotating pods for enhanced maneuverability compared to traditional fixed shaftline propulsion.

Shaft Generator

Podded propulsion systems integrate compact shaft generators directly with electric motors, offering higher efficiency and reduced maintenance compared to traditional shaftline generators.

Stern Tube Sealing

Podded propulsion systems eliminate stern tube sealing issues inherent in traditional shaftline setups by integrating propulsion units externally, reducing maintenance and leakage risks.

Podded Propulsion vs Traditional Shaftline Infographic

njnir.com

njnir.com