Exhaust gas recirculation (EGR) reduces nitrogen oxide (NOx) emissions by recirculating a portion of exhaust gases back into the engine's intake, lowering combustion temperatures and minimizing NOx formation. Selective catalytic reduction (SCR) uses a catalyst and a reductant, typically urea, to chemically convert NOx into harmless nitrogen and water downstream of the engine. EGR is integrated within the engine cycle, improving fuel efficiency but with limited NOx reduction, while SCR offers higher NOx abatement efficiency and is suited for meeting stricter emission regulations in marine engines.

Table of Comparison

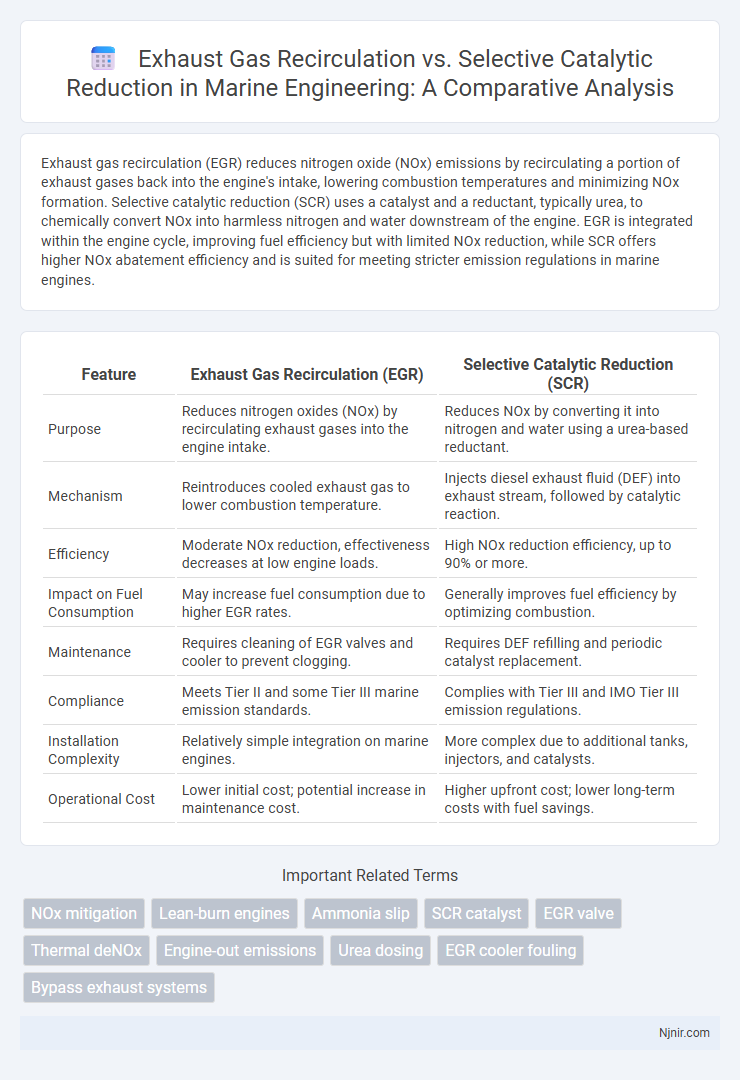

| Feature | Exhaust Gas Recirculation (EGR) | Selective Catalytic Reduction (SCR) |

|---|---|---|

| Purpose | Reduces nitrogen oxides (NOx) by recirculating exhaust gases into the engine intake. | Reduces NOx by converting it into nitrogen and water using a urea-based reductant. |

| Mechanism | Reintroduces cooled exhaust gas to lower combustion temperature. | Injects diesel exhaust fluid (DEF) into exhaust stream, followed by catalytic reaction. |

| Efficiency | Moderate NOx reduction, effectiveness decreases at low engine loads. | High NOx reduction efficiency, up to 90% or more. |

| Impact on Fuel Consumption | May increase fuel consumption due to higher EGR rates. | Generally improves fuel efficiency by optimizing combustion. |

| Maintenance | Requires cleaning of EGR valves and cooler to prevent clogging. | Requires DEF refilling and periodic catalyst replacement. |

| Compliance | Meets Tier II and some Tier III marine emission standards. | Complies with Tier III and IMO Tier III emission regulations. |

| Installation Complexity | Relatively simple integration on marine engines. | More complex due to additional tanks, injectors, and catalysts. |

| Operational Cost | Lower initial cost; potential increase in maintenance cost. | Higher upfront cost; lower long-term costs with fuel savings. |

Introduction to Emission Control Technologies in Marine Engineering

Exhaust gas recirculation (EGR) reduces nitrogen oxide (NOx) emissions by recirculating a portion of exhaust gases back into the engine intake, lowering combustion temperatures in marine diesel engines. Selective catalytic reduction (SCR) employs a catalyst and reductant, typically ammonia or urea, to convert NOx into harmless nitrogen and water in the exhaust stream, achieving higher NOx reduction efficiency. Both technologies are critical emission control strategies in marine engineering, addressing stringent International Maritime Organization (IMO) Tier III standards for NOx emissions reduction.

Fundamentals of Exhaust Gas Recirculation (EGR) Systems

Exhaust Gas Recirculation (EGR) systems reduce nitrogen oxide (NOx) emissions by recirculating a portion of exhaust gases back into the engine intake, lowering combustion temperatures and oxygen concentration. EGR fundamentally operates through either high-pressure or low-pressure loops, controlling the flow rate via valves to optimize emission reduction and engine performance. Unlike Selective Catalytic Reduction (SCR), which uses a urea-based reagent to chemically convert NOx into nitrogen and water, EGR primarily focuses on modifying combustion conditions to prevent NOx formation at the source.

Principles of Selective Catalytic Reduction (SCR) Systems

Selective Catalytic Reduction (SCR) systems reduce nitrogen oxides (NOx) emissions by injecting a reductant, typically ammonia or urea, into the exhaust stream, which then reacts over a catalyst to convert NOx into harmless nitrogen and water. The catalyst in SCR systems, often composed of materials like vanadium, titanium, or zeolites, facilitates the chemical reaction at temperatures ranging from 200degC to 450degC. Unlike Exhaust Gas Recirculation (EGR), which lowers combustion temperature by recirculating exhaust gases back into the engine, SCR offers higher NOx reduction efficiency and better fuel economy by treating emissions post-combustion.

Comparative Analysis: EGR vs SCR in Marine Applications

Exhaust Gas Recirculation (EGR) reduces nitrogen oxides (NOx) emissions by recirculating a portion of the exhaust gases back into the combustion chamber, lowering combustion temperatures in marine engines. Selective Catalytic Reduction (SCR) uses a urea-based reagent injected into the exhaust stream, converting NOx into nitrogen and water, achieving higher NOx reduction efficiency often exceeding 90%. In marine applications, SCR systems offer superior compliance with IMO Tier III emission standards, while EGR systems provide lower operational complexity and fuel penalty but are less effective in meeting stringent NOx limits.

Impact on NOx Emissions in Marine Engines

Exhaust gas recirculation (EGR) reduces NOx emissions in marine engines by recirculating a portion of exhaust gases back into the combustion chamber, lowering combustion temperatures and thus limiting NOx formation. Selective catalytic reduction (SCR) uses a catalyst and a reductant, usually urea, to chemically convert NOx into nitrogen and water after combustion, achieving higher NOx removal efficiency compared to EGR. While EGR is effective at reducing NOx upstream, SCR systems typically achieve over 90% NOx reduction, making them the preferred technology for meeting stringent IMO Tier III emissions standards in marine applications.

Operational Efficiency and Fuel Consumption

Exhaust gas recirculation (EGR) improves operational efficiency by reducing nitrogen oxide (NOx) emissions through recirculating a portion of the exhaust gases back into the combustion chamber, which lowers combustion temperatures and enhances fuel economy by enabling leaner fuel mixtures. Selective catalytic reduction (SCR) achieves higher NOx reduction rates by injecting a urea-based reductant into the exhaust stream, but it may result in slightly increased fuel consumption due to the energy required for urea injection and catalyst operation. EGR systems generally offer better fuel efficiency in light-duty applications, while SCR systems provide superior emission control in heavy-duty engines, balancing operational efficiency and fuel consumption depending on engine type and emission regulation requirements.

Installation and Maintenance Challenges

Exhaust gas recirculation (EGR) systems present installation challenges due to their integration with the engine's intake and exhaust pathways, requiring precise modifications to ensure proper flow and cooling, and regular maintenance to prevent soot buildup and valve clogging. Selective catalytic reduction (SCR) systems demand additional space for the catalyst and urea injection system, with maintenance focused on ensuring the injector and catalyst remain free of contamination and that urea dosing systems function correctly. Both technologies require specialized diagnostics for effective troubleshooting, but SCR typically involves more complex chemical handling and regulatory compliance during upkeep.

Environmental and Regulatory Compliance

Exhaust gas recirculation (EGR) reduces nitrogen oxide (NOx) emissions by recirculating a portion of exhaust gases back into the engine cylinders, lowering combustion temperatures and meeting EPA and Euro 6 emission standards. Selective catalytic reduction (SCR) uses a urea-based additive to chemically convert NOx into nitrogen and water, achieving higher NOx reduction levels required for stringent Tier 4 and Euro 7 regulations. Both technologies play critical roles in modern diesel engine compliance, with SCR systems increasingly favored for heavy-duty applications due to superior NOx control and regulatory alignment.

Cost Implications of EGR and SCR Systems

Exhaust Gas Recirculation (EGR) systems typically incur lower initial installation costs compared to Selective Catalytic Reduction (SCR) systems due to simpler hardware and integration requirements. SCR technology involves higher upfront expenses driven by the need for urea-based diesel exhaust fluid (DEF), catalyst units, and complex dosing controls, increasing operational costs over time. However, SCR systems often achieve greater NOx reduction efficiency, potentially offsetting long-term costs through compliance with stringent emission regulations and improved fuel economy.

Future Trends in Marine Emission Reduction Technologies

Exhaust Gas Recirculation (EGR) and Selective Catalytic Reduction (SCR) are pivotal in reducing NOx emissions in marine engines, with SCR showing increased adoption for its higher efficiency and lower fuel consumption. Future trends indicate the integration of hybrid systems combining EGR and SCR technology to meet stringent IMO Tier III regulations and emerging carbon-neutral fuels. Advances in sensor technology and digital monitoring are expected to optimize emission control systems, enhancing environmental compliance while reducing operational costs for the shipping industry.

NOx mitigation

Exhaust gas recirculation reduces NOx by recirculating a portion of exhaust gases to lower combustion temperature, while selective catalytic reduction uses ammonia or urea to chemically convert NOx into nitrogen and water in the exhaust stream.

Lean-burn engines

Exhaust gas recirculation (EGR) reduces nitrogen oxide emissions in lean-burn engines by recirculating a portion of exhaust gases to lower combustion temperatures, while selective catalytic reduction (SCR) uses a urea-based catalyst to convert nitrogen oxides into nitrogen and water, offering more effective emission control in stringent regulatory environments.

Ammonia slip

Selective catalytic reduction reduces NOx emissions more effectively than exhaust gas recirculation but often results in higher ammonia slip, requiring careful management to minimize environmental impact.

SCR catalyst

Selective catalytic reduction (SCR) catalyst efficiently reduces nitrogen oxides (NOx) in exhaust gases by converting them into nitrogen and water using a urea-based reductant, outperforming exhaust gas recirculation (EGR) systems in NOx reduction and fuel efficiency.

EGR valve

The EGR valve reduces nitrogen oxide emissions by recirculating exhaust gases into the combustion chamber, while selective catalytic reduction uses a catalyst to convert NOx into nitrogen and water.

Thermal deNOx

Thermal deNOx achieves nitrogen oxide reduction at high temperatures by promoting thermal decomposition, whereas Exhaust Gas Recirculation lowers combustion temperature to reduce NOx formation and Selective Catalytic Reduction uses ammonia or urea injection with a catalyst to convert NOx into nitrogen and water.

Engine-out emissions

Exhaust gas recirculation reduces engine-out NOx emissions by recirculating a portion of exhaust gases back into the combustion chamber, while selective catalytic reduction treats engine-out NOx emissions downstream by injecting a urea-based additive into the exhaust stream.

Urea dosing

Urea dosing in selective catalytic reduction (SCR) systems precisely injects ammonia-based solutions to reduce NOx emissions, whereas exhaust gas recirculation (EGR) decreases NOx by recirculating a portion of exhaust gases to lower combustion temperatures without using urea dosing.

EGR cooler fouling

Exhaust gas recirculation (EGR) systems frequently experience cooler fouling due to particulate and soot accumulation, which reduces heat exchange efficiency and increases maintenance needs, whereas selective catalytic reduction (SCR) systems avoid direct cooling of recirculated gases, minimizing fouling issues but requiring urea injection for NOx reduction.

Bypass exhaust systems

Bypass exhaust systems in Exhaust Gas Recirculation (EGR) reduce NOx by recirculating a portion of exhaust gases to the intake, whereas Selective Catalytic Reduction (SCR) systems treat NOx chemically downstream using a urea-based additive.

Exhaust gas recirculation vs selective catalytic reduction Infographic

njnir.com

njnir.com