Variable frequency drives (VFDs) offer precise control over marine propulsion systems by adjusting motor speed through electrical frequency modulation, leading to improved fuel efficiency and reduced mechanical wear. Mechanical speed control relies on physical components such as gears and clutches, which can introduce higher maintenance costs and less responsive speed adjustments. VFD technology enhances vessel performance and reliability, making it a preferred choice for modern marine engineering applications.

Table of Comparison

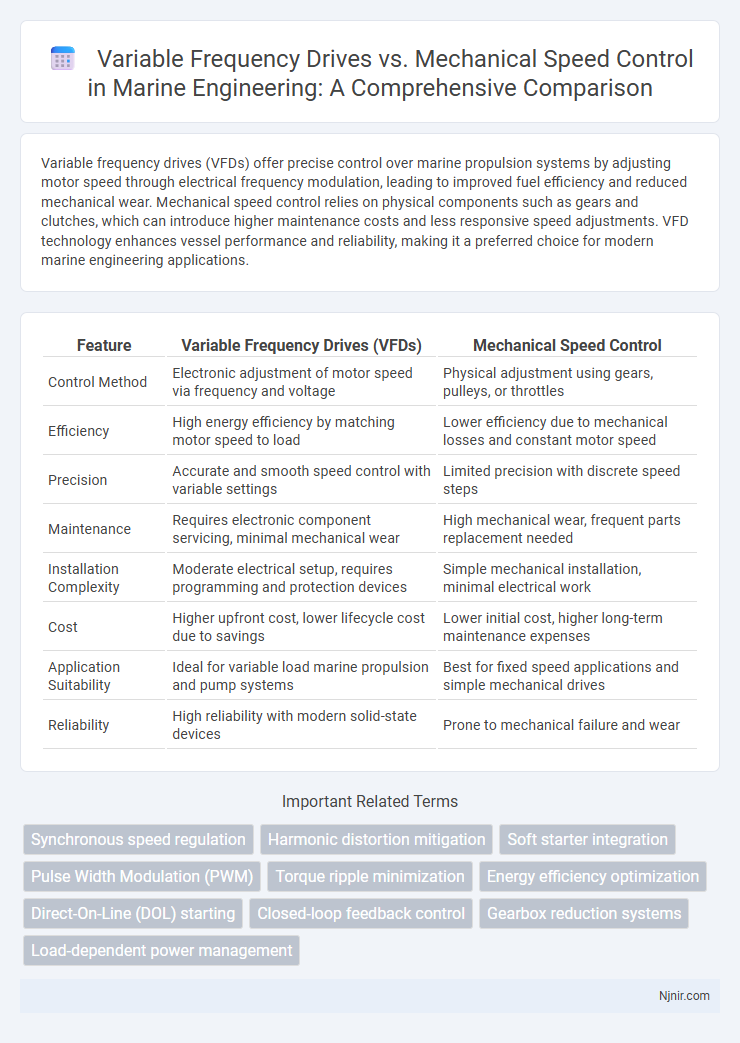

| Feature | Variable Frequency Drives (VFDs) | Mechanical Speed Control |

|---|---|---|

| Control Method | Electronic adjustment of motor speed via frequency and voltage | Physical adjustment using gears, pulleys, or throttles |

| Efficiency | High energy efficiency by matching motor speed to load | Lower efficiency due to mechanical losses and constant motor speed |

| Precision | Accurate and smooth speed control with variable settings | Limited precision with discrete speed steps |

| Maintenance | Requires electronic component servicing, minimal mechanical wear | High mechanical wear, frequent parts replacement needed |

| Installation Complexity | Moderate electrical setup, requires programming and protection devices | Simple mechanical installation, minimal electrical work |

| Cost | Higher upfront cost, lower lifecycle cost due to savings | Lower initial cost, higher long-term maintenance expenses |

| Application Suitability | Ideal for variable load marine propulsion and pump systems | Best for fixed speed applications and simple mechanical drives |

| Reliability | High reliability with modern solid-state devices | Prone to mechanical failure and wear |

Introduction to Speed Control in Marine Engineering

Variable frequency drives (VFDs) offer precise and energy-efficient speed control of marine propulsion systems by adjusting motor frequency and voltage, enhancing vessel performance and fuel economy. Mechanical speed control methods, such as gearboxes and hydraulic drives, provide less flexibility and often involve higher maintenance due to wear and tear of mechanical components. VFDs facilitate smoother acceleration, improved torque control, and integration with digital monitoring systems, making them increasingly preferred in modern marine engineering applications.

Overview of Variable Frequency Drives (VFDs)

Variable Frequency Drives (VFDs) regulate motor speed by adjusting the frequency and voltage of electrical power supplied to the motor, offering precise speed control and energy efficiency. VFDs improve process control, reduce mechanical stress on equipment, and enable soft start and stop functions that extend motor lifespan. Compared to mechanical speed control methods, VFDs provide a versatile, electronically controlled solution that enhances performance in HVAC, manufacturing, and pumping applications.

Mechanical Speed Control Methods Explained

Mechanical speed control methods primarily involve adjusting the rotational speed through physical modifications such as gearboxes, variable pitch pulleys, or friction-based clutches to regulate torque and speed output. These techniques rely on changing the mechanical leverage or slip, offering simplicity and robustness but often result in energy losses and limited precision. Compared to variable frequency drives (VFDs), mechanical methods lack the fine speed tuning, energy efficiency, and dynamic control afforded by electronically adjusting motor input frequency and voltage.

Energy Efficiency: VFDs vs Mechanical Systems

Variable frequency drives (VFDs) provide superior energy efficiency compared to mechanical speed control systems by precisely adjusting motor speed to match load requirements, reducing energy waste. Mechanical systems often operate at fixed speeds with energy losses in throttling or slipping mechanisms, resulting in higher power consumption. Implementing VFDs can achieve energy savings of up to 50% in applications such as HVAC, pumps, and fans by optimizing motor performance and minimizing unnecessary energy use.

Precision and Response in Speed Regulation

Variable frequency drives (VFDs) offer superior precision and rapid response in speed regulation compared to mechanical speed control methods, enabling fine adjustments to motor speed with minimal delay. VFDs utilize electronic control to modulate frequency and voltage, achieving consistent speed accuracy often within fractions of a percent, whereas mechanical speed controls rely on physical components that introduce lag and variability. This electronic modulation enhances dynamic performance in applications demanding quick speed changes and stable operation under varying loads.

Installation and Maintenance Considerations

Variable frequency drives (VFDs) offer easier installation with compact size and fewer mechanical components compared to bulky mechanical speed control systems, reducing the need for extensive shaft alignment and coupling. VFDs require minimal maintenance mainly focused on electrical components such as capacitors and cooling systems, whereas mechanical speed controls demand regular lubrication, inspection of gears, bearings, and belts to prevent wear. The modular design of VFDs also supports remote diagnostics and firmware updates, significantly lowering downtime and maintenance costs relative to mechanical systems.

Impact on Marine System Reliability and Lifespan

Variable frequency drives (VFDs) enhance marine system reliability by providing precise motor speed control, reducing mechanical stress and minimizing wear on components compared to traditional mechanical speed control methods. VFDs improve energy efficiency and allow smoother acceleration and deceleration, which significantly extends the lifespan of marine propulsion systems and auxiliary equipment. The reduced maintenance requirements and lower risk of mechanical failures with VFD technology contribute to higher operational uptime and overall marine system durability.

Cost Analysis: Initial Investment and Lifecycle Costs

Variable frequency drives (VFDs) typically require a higher initial investment compared to mechanical speed control systems due to the cost of electronic components and installation. However, VFDs offer lower lifecycle costs through energy savings, reduced maintenance, and improved system efficiency, which often results in a favorable return on investment over time. Mechanical speed control systems incur less upfront cost but tend to have higher ongoing expenses from wear and frequent maintenance, leading to increased total cost of ownership.

Environmental Impacts and Regulatory Compliance

Variable frequency drives (VFDs) significantly reduce energy consumption compared to mechanical speed controls by precisely adjusting motor speeds, leading to lower greenhouse gas emissions and decreased environmental footprint. VFDs comply with stringent energy efficiency regulations such as the IEC 60034-30 and the U.S. Department of Energy standards, facilitating adherence to global environmental policies. Mechanical speed controls generally lack the precision and efficiency of VFDs, often resulting in higher energy waste and difficulty meeting evolving regulatory requirements.

Choosing the Right Speed Control Solution for Marine Applications

Variable frequency drives (VFDs) offer precise speed control, energy efficiency, and reduced mechanical wear compared to traditional mechanical speed control systems in marine applications. VFDs enable seamless adjustment of motor speed and torque, improving fuel efficiency and reducing emissions in vessels. Selecting VFD technology over mechanical methods enhances reliability, lowers maintenance costs, and supports compliance with stringent maritime regulations.

Synchronous speed regulation

Variable frequency drives enable precise synchronous speed regulation by adjusting motor electrical frequency, whereas mechanical speed control relies on physical components that offer less accuracy and flexibility.

Harmonic distortion mitigation

Variable frequency drives reduce harmonic distortion more effectively than mechanical speed control by utilizing advanced pulse-width modulation techniques.

Soft starter integration

Variable frequency drives outperform mechanical speed controls by enabling seamless soft starter integration, enhancing motor protection and energy efficiency.

Pulse Width Modulation (PWM)

Variable frequency drives use pulse width modulation (PWM) to efficiently control motor speed by varying voltage and frequency, offering more precise, energy-saving performance compared to traditional mechanical speed control methods.

Torque ripple minimization

Variable frequency drives minimize torque ripple more effectively than mechanical speed control by providing precise, smooth motor speed adjustments through electronic modulation.

Energy efficiency optimization

Variable frequency drives optimize energy efficiency by precisely adjusting motor speed to match load demands, outperforming mechanical speed controls that waste energy through friction and fixed-speed operation.

Direct-On-Line (DOL) starting

Variable frequency drives offer precise speed control and energy efficiency compared to mechanical speed control, while Direct-On-Line (DOL) starting provides a simple, low-cost method with high starting current but limited speed variation.

Closed-loop feedback control

Variable frequency drives use closed-loop feedback control for precise motor speed regulation, unlike mechanical speed controls that lack real-time adjustment capabilities.

Gearbox reduction systems

Variable frequency drives enhance energy efficiency and precision in speed control compared to traditional mechanical gearbox reduction systems by eliminating gear wear and enabling smoother motor speed adjustments.

Load-dependent power management

Variable frequency drives optimize load-dependent power management by adjusting motor speed to match demand, significantly reducing energy consumption compared to fixed mechanical speed controls.

Variable frequency drives vs mechanical speed control Infographic

njnir.com

njnir.com