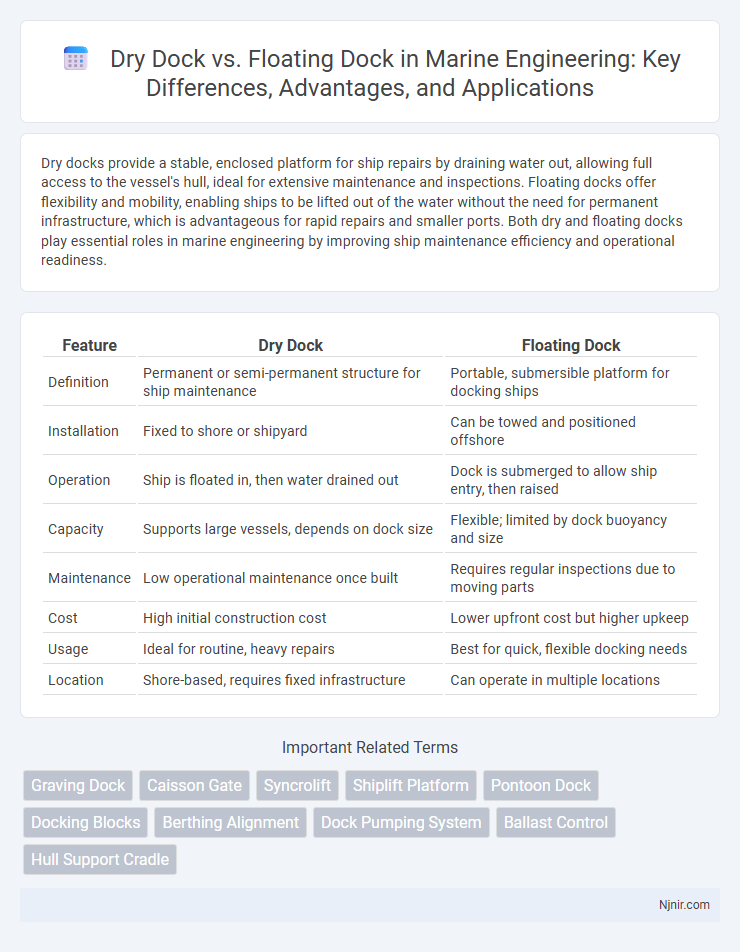

Dry docks provide a stable, enclosed platform for ship repairs by draining water out, allowing full access to the vessel's hull, ideal for extensive maintenance and inspections. Floating docks offer flexibility and mobility, enabling ships to be lifted out of the water without the need for permanent infrastructure, which is advantageous for rapid repairs and smaller ports. Both dry and floating docks play essential roles in marine engineering by improving ship maintenance efficiency and operational readiness.

Table of Comparison

| Feature | Dry Dock | Floating Dock |

|---|---|---|

| Definition | Permanent or semi-permanent structure for ship maintenance | Portable, submersible platform for docking ships |

| Installation | Fixed to shore or shipyard | Can be towed and positioned offshore |

| Operation | Ship is floated in, then water drained out | Dock is submerged to allow ship entry, then raised |

| Capacity | Supports large vessels, depends on dock size | Flexible; limited by dock buoyancy and size |

| Maintenance | Low operational maintenance once built | Requires regular inspections due to moving parts |

| Cost | High initial construction cost | Lower upfront cost but higher upkeep |

| Usage | Ideal for routine, heavy repairs | Best for quick, flexible docking needs |

| Location | Shore-based, requires fixed infrastructure | Can operate in multiple locations |

Introduction to Dry Docks and Floating Docks

Dry docks are specialized structures used for the maintenance, repair, and construction of ships by draining water to provide a stable platform for workers. Floating docks are mobile platforms that can be submerged to allow a vessel to float in and then raised to lift the ship out of the water for similar purposes. Both types of docks play a crucial role in shipyard operations, with dry docks offering fixed facilities and floating docks providing greater flexibility in location and usage.

Key Differences Between Dry Docks and Floating Docks

Dry docks are fixed structures built on land, designed to drain water and provide a stable platform for ship repairs and maintenance. Floating docks are movable, submersible platforms that lift vessels out of the water using buoyancy, allowing flexibility in location and ease of access. Key differences include stability, with dry docks offering a solid foundation, and versatility, as floating docks can accommodate various ship sizes and be relocated as needed.

Structural Design and Construction

Dry docks feature a fixed, basin-like structure with reinforced concrete or steel walls designed to be drained for underwater hull access, ensuring stability and durability for heavy ship repairs. Floating docks consist of a pontoon or barge-like platform with a submerged hull section, engineered for buoyancy and mobility using ballast tanks that adjust water displacement for lifting vessels. Structural design in dry docks emphasizes permanent strength and watertight integrity, whereas floating docks prioritize flexibility, modular construction, and ease of relocation.

Functional Applications in Marine Engineering

Dry docks provide a stable, enclosed environment for extensive ship repairs, hull inspections, and construction, enabling precise maintenance below the waterline. Floating docks offer flexible, mobile solutions for repairing smaller vessels or conducting quick maintenance without requiring permanent infrastructure. Marine engineers select dry docks for heavy-duty structural work and floating docks for cost-effective, adaptable ship servicing in various locations.

Maintenance Procedures and Accessibility

Dry docks offer comprehensive maintenance procedures by fully draining water to expose the vessel's hull, allowing detailed inspection, cleaning, and repairs below the waterline with stable and secure access. Floating docks provide more flexible accessibility by submerging to allow vessels to float in and then raising them above water, but maintenance is often limited to less extensive repairs due to potential movement and space constraints. Both docks support critical maintenance tasks, yet dry docks enable more thorough hull work, while floating docks prioritize rapid accessibility and operational efficiency.

Cost Analysis and Economic Considerations

Dry docks typically involve higher initial capital expenditure due to the construction of permanent infrastructure, but they offer lower operational costs over time through enhanced maintenance efficiency and longer service life. Floating docks present a more flexible and cost-effective solution with lower upfront costs and rapid deployment, though they can incur higher maintenance expenses and limited scalability. Economic considerations must weigh long-term asset depreciation, regional labor costs, and the frequency of dock usage to determine the optimal cost-benefit balance between dry docks and floating docks.

Environmental Impact and Safety Factors

Dry docks minimize water contamination risks by allowing vessels to be serviced out of water, reducing pollutant discharge and sediment disturbance, while floating docks may lead to localized water pollution due to in-water maintenance activities. Safety in dry docks is enhanced by stable, solid platforms that facilitate secure access and reduce hazards associated with water currents or buoyancy fluctuations often present in floating docks. Environmental regulations tend to favor dry docks for their containment capabilities, whereas floating docks require stringent monitoring to prevent ecological harm from spills or debris.

Advantages of Dry Docks for Ship Repairs

Dry docks offer significant advantages for ship repairs by providing a stable, dry environment that ensures easier access to the hull and underwater components, enabling more precise inspection and maintenance. They accommodate larger vessels with heavy equipment, allowing comprehensive structural repairs and heavy machinery overhauls that floating docks cannot efficiently support. The controlled setting of dry docks enhances safety, reduces environmental risks, and facilitates the use of specialized tools and materials essential for high-quality ship refurbishment.

Benefits of Floating Docks in Modern Shipping

Floating docks offer superior flexibility in modern shipping by enabling vessels to be serviced and repaired without the need for permanent infrastructure. Their adaptability allows for rapid deployment in various locations, reducing downtime and operational costs for shipowners. Enhanced safety features and the ability to accommodate a wide range of ship sizes make floating docks an essential asset in efficient maritime maintenance and logistics.

Choosing the Right Dock: Factors to Consider

Choosing the right dock depends on factors like vessel size, maintenance needs, and budget constraints. Dry docks provide stable, secure environments ideal for extensive underwater repairs, while floating docks offer flexibility and faster setup for smaller vessels or temporary projects. Assessing dock capacity, environmental conditions, and long-term operational costs ensures optimal decision-making for maintenance efficiency and vessel safety.

Graving Dock

A graving dock, a type of dry dock, is a fixed structure used for ship repair and construction by draining water to expose the vessel's hull, contrasting with floating docks that submerge and lift ships using buoyancy for maintenance.

Caisson Gate

Caisson gates in dry docks provide a watertight seal for maintenance on stationary vessels, while floating docks use caisson gates to submerge and lift ships for flexible, mobile repairs.

Syncrolift

Syncrolift dry docks provide efficient vessel lifting and transfer compared to traditional floating docks by enabling faster, safer, and more precise ship repairs and maintenance.

Shiplift Platform

A shiplift platform offers a versatile alternative to dry docks and floating docks by vertically lifting vessels out of the water for maintenance, enabling faster turnaround and space-efficient operations.

Pontoon Dock

Pontoon docks, a type of floating dock, offer versatile, buoyant platforms ideal for temporary or permanent marine vessel maintenance compared to fixed, basin-style dry docks.

Docking Blocks

Docking blocks in dry docks provide stable support for a vessel's hull during repairs, while floating docks use adjustable blocks that rise and fall with water levels to facilitate vessel positioning and maintenance.

Berthing Alignment

Dry docks provide precise berthing alignment through fixed structural guides, whereas floating docks offer more flexible but less stable alignment due to their buoyant, movable nature.

Dock Pumping System

Dry dock pumping systems utilize high-capacity centrifugal pumps to rapidly remove water for vessel maintenance, whereas floating dock pumping systems rely on integrated ballast pumps to control buoyancy and stability during docking operations.

Ballast Control

Dry docks achieve precise ballast control by draining water to expose vessels for maintenance, while floating docks maintain vessel buoyancy and stability through adjustable ballast tanks submerged in water.

Hull Support Cradle

Dry docks provide stable, rigid hull support cradles for precise maintenance, while floating docks use adjustable, buoyant cradles to accommodate different hull shapes and sizes during repairs.

Dry Dock vs Floating Dock Infographic

njnir.com

njnir.com