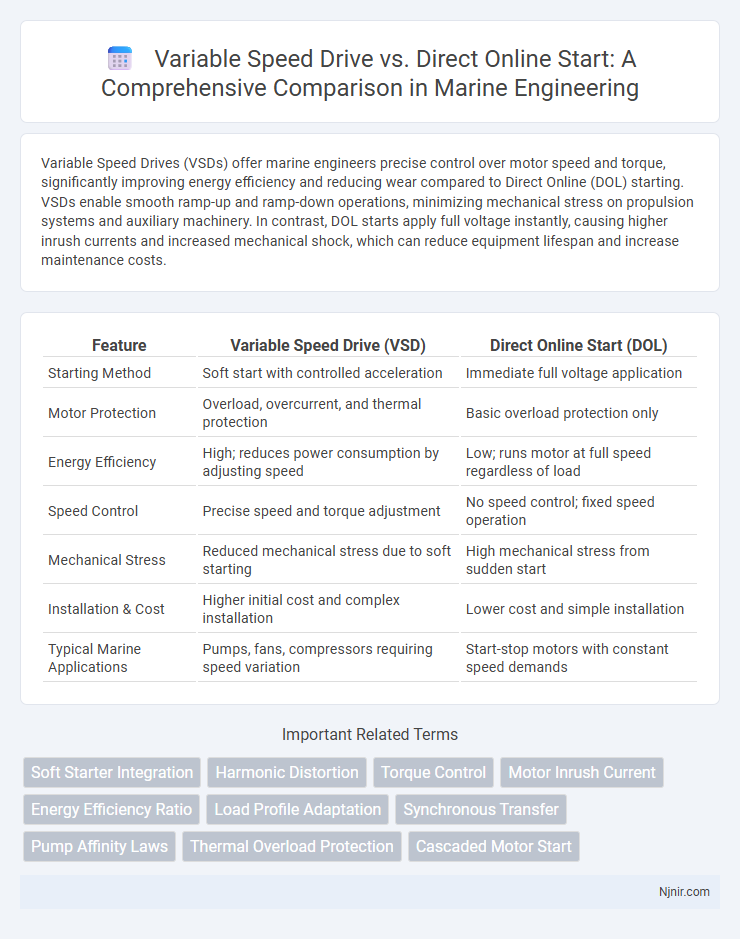

Variable Speed Drives (VSDs) offer marine engineers precise control over motor speed and torque, significantly improving energy efficiency and reducing wear compared to Direct Online (DOL) starting. VSDs enable smooth ramp-up and ramp-down operations, minimizing mechanical stress on propulsion systems and auxiliary machinery. In contrast, DOL starts apply full voltage instantly, causing higher inrush currents and increased mechanical shock, which can reduce equipment lifespan and increase maintenance costs.

Table of Comparison

| Feature | Variable Speed Drive (VSD) | Direct Online Start (DOL) |

|---|---|---|

| Starting Method | Soft start with controlled acceleration | Immediate full voltage application |

| Motor Protection | Overload, overcurrent, and thermal protection | Basic overload protection only |

| Energy Efficiency | High; reduces power consumption by adjusting speed | Low; runs motor at full speed regardless of load |

| Speed Control | Precise speed and torque adjustment | No speed control; fixed speed operation |

| Mechanical Stress | Reduced mechanical stress due to soft starting | High mechanical stress from sudden start |

| Installation & Cost | Higher initial cost and complex installation | Lower cost and simple installation |

| Typical Marine Applications | Pumps, fans, compressors requiring speed variation | Start-stop motors with constant speed demands |

Introduction to Marine Motor Starting Methods

Marine motor starting methods primarily include Variable Speed Drives (VSD) and Direct Online (DOL) starting, each serving distinct operational requirements. VSD offers precise speed control and energy efficiency by adjusting motor voltage and frequency, reducing mechanical stress in marine propulsion systems. In contrast, DOL start applies full voltage immediately, ensuring simple, robust, and cost-effective motor engagement for straightforward marine applications.

Overview of Variable Speed Drives (VSD)

Variable Speed Drives (VSD) regulate motor speed by adjusting voltage and frequency, optimizing energy consumption and enhancing process control. Unlike Direct Online Start (DOL), which applies full voltage instantly, VSDs provide gradual startup, reducing mechanical stress and electrical demand. The advanced control features of VSDs lead to improved system efficiency and reduced operational costs in industrial applications.

Understanding Direct Online (DOL) Starters

Direct Online (DOL) starters provide a simple method to start electric motors by applying full line voltage directly, ensuring quick and efficient motor startup. This approach lacks the voltage control found in Variable Speed Drives (VSDs), resulting in higher inrush currents and mechanical stress on equipment. DOL starters are ideal for small motors with low starting torque requirements, offering cost-effective and straightforward motor control without the complexity of speed regulation.

Energy Efficiency Comparison: VSD vs DOL

Variable Speed Drives (VSDs) significantly improve energy efficiency compared to Direct Online (DOL) starters by adjusting motor speed to match load requirements, resulting in reduced power consumption and lower operational costs. DOL starters operate motors at full speed regardless of demand, causing unnecessary energy waste and increased wear on equipment. Studies show VSDs can achieve energy savings of up to 30-50% in variable load applications, highlighting their superior efficiency over DOL systems.

Impact on Marine Electrical Systems

Variable Speed Drives (VSDs) enhance marine electrical systems by reducing inrush current and providing precise motor speed control, resulting in improved energy efficiency and extended equipment lifespan. In contrast, Direct Online Start (DOL) methods cause high starting currents that can lead to electrical component stress, voltage dips, and increased maintenance costs. Implementing VSDs minimizes electrical disturbances in shipboard power networks, optimizing operational reliability and reducing downtime.

Mechanical Stress and Equipment Lifespan

Variable Speed Drives (VSDs) significantly reduce mechanical stress on equipment by enabling smooth acceleration and deceleration, which minimizes wear and tear on motors and connected machinery. Direct Online (DOL) starting causes a sudden inrush of current leading to high mechanical stress due to abrupt torque, increasing the likelihood of equipment fatigue and shortened lifespan. Utilizing VSDs extends equipment lifespan by preventing shock loads and thermal stress, ensuring more reliable and efficient operation over time.

Application Suitability in Marine Engineering

Variable Speed Drives (VSDs) offer precise control of motor speed and torque, making them ideal for applications requiring energy efficiency and smooth acceleration in marine engineering, such as pump systems and propulsion control. Direct Online (DOL) Start is more suitable for simple, robust applications where cost-effectiveness and straightforward operation are priorities, commonly used for low-power motors in auxiliary systems on vessels. Marine engineering favors VSDs for complex, variable-load equipment, while DOL remains preferred for steady-load scenarios requiring less control complexity.

Installation and Maintenance Considerations

Variable Speed Drives (VSDs) require more complex installation involving precise wiring, programming, and integration with control systems, while Direct Online (DOL) starters offer simpler, straightforward setup with minimal wiring. Maintenance for VSDs involves regular firmware updates, cooling system checks, and electronic component inspections, contrasting with DOL starters that primarily need mechanical inspections and contactor replacements. The choice impacts long-term operational costs, with VSDs demanding specialized skill sets for troubleshooting compared to the basic electrical maintenance of DOL starters.

Cost Analysis: Initial and Operational Expenses

Variable Speed Drives (VSDs) generally involve higher initial costs due to advanced electronics and installation requirements, but they offer significant operational savings by optimizing energy consumption and reducing mechanical wear. Direct Online (DOL) starting systems have lower upfront expenses and simpler installation but result in higher energy costs and increased mechanical stress during motor startup, leading to frequent maintenance. Over time, VSDs provide better cost efficiency through reduced electricity bills and extended equipment lifespan compared to DOL starters.

Choosing the Right Starting Method for Marine Applications

Variable Speed Drives (VSDs) offer precise motor control and energy efficiency, making them ideal for marine applications where load variations and smooth starting are critical. Direct Online (DOL) starting provides simple, cost-effective motor startup but can cause high inrush currents and mechanical stress, posing risks in sensitive marine environments. Selecting the right starting method depends on vessel size, motor load characteristics, and operational requirements, with VSDs favored for energy savings and reduced wear, while DOL suits smaller, uncomplicated setups.

Soft Starter Integration

Variable Speed Drives provide precise motor control and energy efficiency, while Direct Online Start offers simple startup; integrating Soft Starters enhances both by reducing inrush current and mechanical stress during motor acceleration.

Harmonic Distortion

Variable Speed Drives reduce harmonic distortion by implementing advanced PWM techniques, whereas Direct Online Start causes higher harmonic distortion due to sudden current surges and lack of harmonic mitigation.

Torque Control

Variable Speed Drives provide precise torque control by adjusting motor speed and current, whereas Direct Online Start delivers full torque instantly without modulation, often causing mechanical stress.

Motor Inrush Current

Variable Speed Drives reduce motor inrush current by gradually ramping up voltage, whereas Direct Online Start causes a high inrush current equal to 6-8 times the motor's full load current.

Energy Efficiency Ratio

Variable Speed Drives improve Energy Efficiency Ratios by adjusting motor speed to match load requirements, unlike Direct Online Starts which operate at full speed regardless of demand.

Load Profile Adaptation

Variable Speed Drives optimize energy consumption by precisely adapting motor speed to load profile variations, whereas Direct Online Start operates motors at full speed regardless of load, leading to inefficiencies.

Synchronous Transfer

Variable Speed Drives enable smooth synchronous transfer by precisely controlling motor acceleration and torque, unlike Direct Online Start which causes abrupt current surges and mechanical stress.

Pump Affinity Laws

Variable Speed Drives optimize pump efficiency by adjusting flow and power according to Pump Affinity Laws, whereas Direct Online Start operates pumps at fixed speed, leading to higher energy consumption and mechanical stress.

Thermal Overload Protection

Variable Speed Drives provide advanced thermal overload protection by continuously monitoring motor temperature and adjusting current flow, whereas Direct Online Start relies on basic thermal relays that offer limited, delayed protection against motor overheating.

Cascaded Motor Start

Cascaded motor start using a Variable Speed Drive reduces inrush current and mechanical stress compared to Direct Online Start by enabling controlled voltage and frequency ramp-up.

Variable Speed Drive vs Direct Online Start Infographic

njnir.com

njnir.com