Hybrid propulsion combines internal combustion engines with electric motors, offering extended range and flexibility for marine vessels compared to full electric systems, which rely solely on battery power and zero emissions. While full electric propulsion ensures silent, eco-friendly operation ideal for short-range or inland waters, hybrid systems enable longer voyages with reduced fuel consumption and lower emissions by optimizing power sources. The choice depends on vessel size, mission profile, and the need for balancing environmental impact with operational range and infrastructure availability.

Table of Comparison

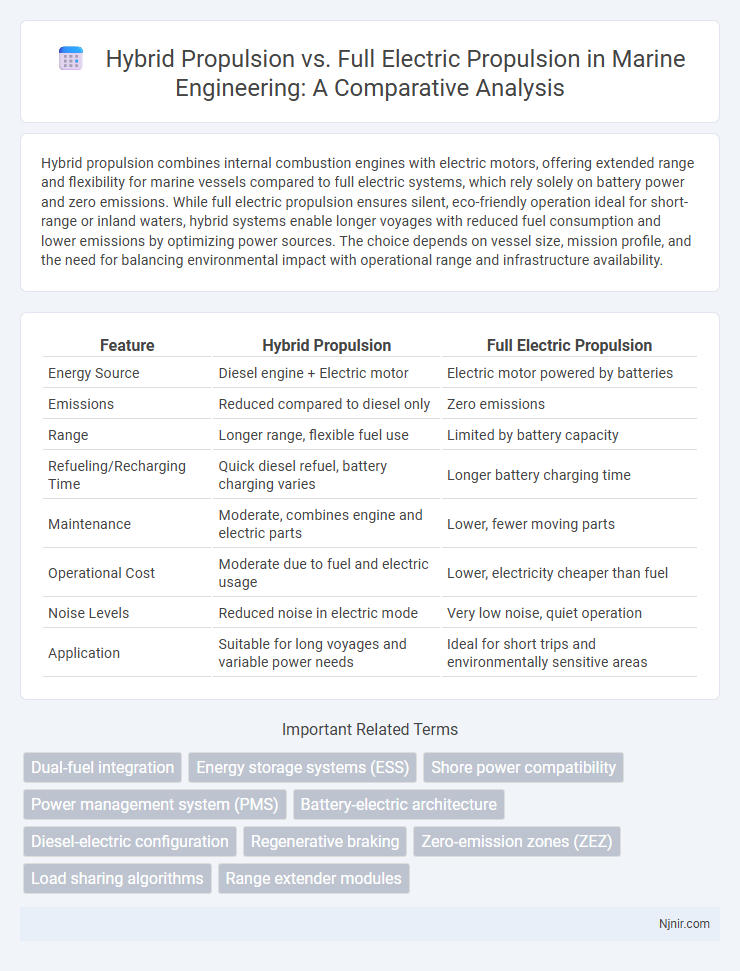

| Feature | Hybrid Propulsion | Full Electric Propulsion |

|---|---|---|

| Energy Source | Diesel engine + Electric motor | Electric motor powered by batteries |

| Emissions | Reduced compared to diesel only | Zero emissions |

| Range | Longer range, flexible fuel use | Limited by battery capacity |

| Refueling/Recharging Time | Quick diesel refuel, battery charging varies | Longer battery charging time |

| Maintenance | Moderate, combines engine and electric parts | Lower, fewer moving parts |

| Operational Cost | Moderate due to fuel and electric usage | Lower, electricity cheaper than fuel |

| Noise Levels | Reduced noise in electric mode | Very low noise, quiet operation |

| Application | Suitable for long voyages and variable power needs | Ideal for short trips and environmentally sensitive areas |

Introduction to Marine Propulsion Systems

Hybrid propulsion systems in marine vessels combine internal combustion engines with electric motors to enhance fuel efficiency and reduce emissions, offering flexibility in power management for various operational conditions. Full electric propulsion relies solely on electric motors powered by batteries or fuel cells, providing zero-emission operation and quieter performance but often limited by battery capacity and range. Marine propulsion systems integrate these technologies to optimize vessel performance, operational costs, and environmental impact, with hybrid systems bridging traditional and electric power advantages.

Overview of Hybrid Propulsion Technology

Hybrid propulsion technology combines internal combustion engines with electric motors to enhance fuel efficiency and reduce emissions in marine and automotive applications. This system allows for optimized power management by switching between or simultaneously using electric and fuel-powered sources, extending range compared to full electric propulsion alone. Key components include batteries, power electronics, and control systems that enable seamless integration and improved operational flexibility.

Fundamentals of Full Electric Propulsion

Full electric propulsion relies solely on battery-stored electrical energy to power electric motors, offering zero tailpipe emissions and high energy efficiency. The system's performance depends on advanced lithium-ion or solid-state batteries, which provide the energy density, power output, and rechargeability necessary for practical application. Innovations in electric motor design and power electronics enable precise control and rapid torque delivery, making full electric propulsion ideal for urban and short-range transport.

Energy Efficiency Comparison

Hybrid propulsion systems combine internal combustion engines with electric motors, allowing optimized energy use by switching between or simultaneously using power sources to reduce fuel consumption and emissions. Full electric propulsion relies solely on battery-stored energy, offering higher energy efficiency by eliminating combustion losses and enabling regenerative braking to recover energy. While full electric systems boast superior energy efficiency due to zero fuel combustion, hybrid systems provide flexibility in longer range applications where battery capacity and charging infrastructure may be limiting factors.

Environmental Impact and Emissions

Hybrid propulsion systems reduce emissions by combining internal combustion engines with electric motors, resulting in lower fuel consumption and decreased greenhouse gas emissions compared to traditional engines. Full electric propulsion eliminates tailpipe emissions entirely, producing zero carbon dioxide and nitrogen oxide emissions during operation, which significantly improves urban air quality. Manufacturing and battery disposal impacts must be considered, but overall, electric propulsion offers the greatest environmental benefits by minimizing pollutant output throughout a vehicle's lifecycle.

Operational Flexibility and Range

Hybrid propulsion systems offer greater operational flexibility by combining internal combustion engines with electric motors, enabling seamless transitions between power sources and extended range capabilities compared to full electric propulsion. Full electric propulsion provides zero-emission operation and quiet performance but is generally limited by battery capacity, resulting in shorter range and longer recharging times. Hybrid systems are ideal for applications requiring variable power demands and longer operational endurance, while full electric systems excel in environments prioritizing sustainability and low noise.

Lifecycle Costs and Maintenance

Hybrid propulsion systems generally incur higher initial costs but offer reduced lifecycle expenses due to fuel flexibility and extended range, balancing fuel consumption and emissions. Full electric propulsion boasts lower maintenance costs because of fewer moving parts and simpler motor design, though battery replacement can significantly impact long-term expenses. Lifecycle cost analysis must consider energy prices, vehicle usage patterns, and battery degradation rates for accurate comparison between hybrid and full electric systems.

Infrastructure and Integration Challenges

Hybrid propulsion systems face fewer infrastructure challenges compared to full electric propulsion, as they can leverage existing fuel supply networks while gradually incorporating electric charging points. Full electric propulsion demands a robust, widespread, and high-capacity charging infrastructure, necessitating significant investment in grid upgrades, fast chargers, and standardized charging protocols. Integration challenges for full electric systems include battery management, thermal regulation, and ensuring compatibility with power grids, whereas hybrid systems require complex synchronization between internal combustion engines and electric motors for seamless operation.

Case Studies in Hybrid and Full Electric Applications

Hybrid propulsion systems demonstrate significant fuel efficiency improvements in maritime case studies, reducing emissions by up to 30% compared to conventional engines. Full electric propulsion applications in urban transit show zero local emissions and lower operational costs, with battery technology driving longer range capabilities and faster charging times. Comparative analyses highlight hybrid systems' advantage in long-haul scenarios, while full electric solutions excel in short-distance, stop-and-go environments.

Future Trends in Marine Propulsion Technologies

Hybrid propulsion systems in marine vessels combine internal combustion engines with electric motors, offering enhanced fuel efficiency and reduced emissions compared to traditional engines. Full electric propulsion, powered solely by batteries or fuel cells, delivers zero emissions and quieter operation, making it ideal for environmentally sensitive areas and short-range applications. Future trends indicate a shift towards increased battery capacity, advanced energy management systems, and integration with renewable energy sources to maximize sustainability and operational flexibility in marine propulsion technologies.

Dual-fuel integration

Dual-fuel hybrid propulsion systems seamlessly integrate traditional engines with electric powertrains to optimize fuel efficiency and reduce emissions compared to full electric propulsion.

Energy storage systems (ESS)

Hybrid propulsion systems utilize combined energy storage systems (ESS) such as batteries and fuel tanks to optimize energy density and recharge flexibility, whereas full electric propulsion relies solely on high-capacity batteries demanding advanced ESS technology for extended range and faster charging.

Shore power compatibility

Hybrid propulsion systems offer greater shore power compatibility by integrating both electric and conventional engines, allowing for flexible charging options compared to fully electric propulsion which relies solely on shore power infrastructure.

Power management system (PMS)

Power management systems in hybrid propulsion optimize energy distribution between fuel engines and electric motors to enhance efficiency, while full electric propulsion relies on PMS to regulate battery output and maintain optimal performance.

Battery-electric architecture

Battery-electric architecture offers higher energy efficiency and zero tailpipe emissions compared to hybrid propulsion systems that combine internal combustion engines with electric motors.

Diesel-electric configuration

Diesel-electric hybrid propulsion combines a diesel engine with electric motors to enhance fuel efficiency, reduce emissions, and provide flexible power management compared to full electric systems limited by battery capacity.

Regenerative braking

Hybrid propulsion systems enhance energy efficiency by utilizing regenerative braking to recover and store kinetic energy, whereas full electric propulsion maximizes this process through more sophisticated regenerative braking technologies integrated with advanced battery management systems.

Zero-emission zones (ZEZ)

Hybrid propulsion extends vehicle range and reduces emissions but full electric propulsion enables zero-emission compliance essential for meeting stringent Zero-emission zones (ZEZ) regulations.

Load sharing algorithms

Load sharing algorithms in hybrid propulsion systems optimize energy distribution between internal combustion engines and electric motors to enhance efficiency and performance, whereas full electric propulsion relies solely on electric motor control without load sharing complexities.

Range extender modules

Range extender modules in hybrid propulsion systems improve overall vehicle range by generating additional electricity on-demand, unlike full electric propulsion which relies solely on battery capacity.

hybrid propulsion vs full electric propulsion Infographic

njnir.com

njnir.com