Condition-based maintenance uses real-time data and sensor analytics to predict equipment failures, optimizing resource allocation and minimizing downtime. Planned maintenance follows a fixed schedule regardless of equipment condition, which can lead to either unnecessary work or unexpected breakdowns. Implementing condition-based maintenance improves asset reliability and reduces operational costs compared to traditional planned maintenance strategies.

Table of Comparison

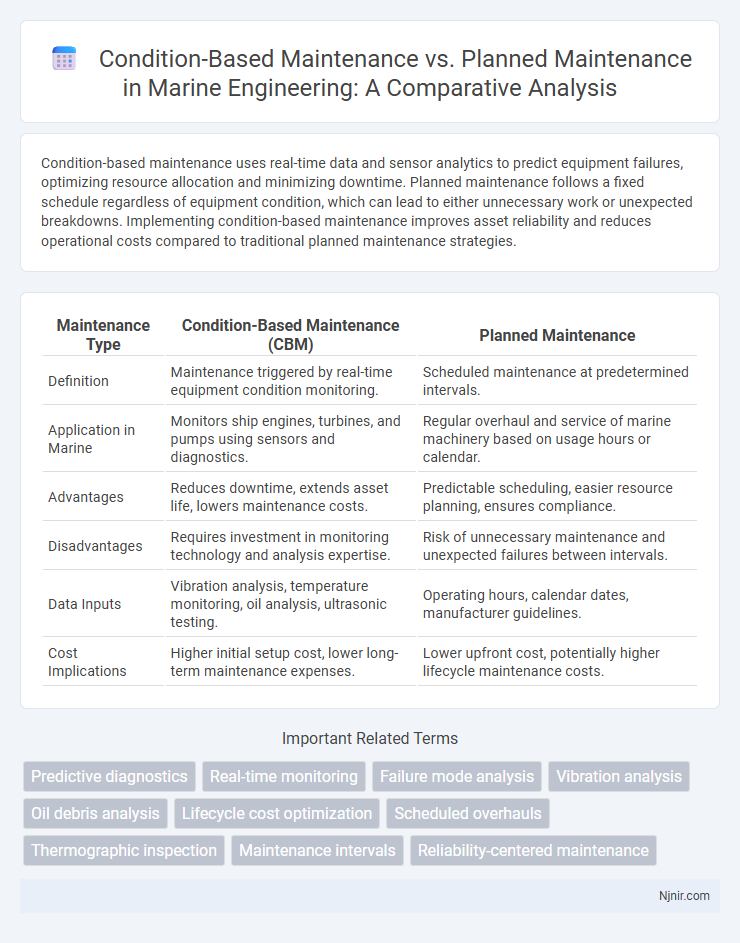

| Maintenance Type | Condition-Based Maintenance (CBM) | Planned Maintenance |

|---|---|---|

| Definition | Maintenance triggered by real-time equipment condition monitoring. | Scheduled maintenance at predetermined intervals. |

| Application in Marine | Monitors ship engines, turbines, and pumps using sensors and diagnostics. | Regular overhaul and service of marine machinery based on usage hours or calendar. |

| Advantages | Reduces downtime, extends asset life, lowers maintenance costs. | Predictable scheduling, easier resource planning, ensures compliance. |

| Disadvantages | Requires investment in monitoring technology and analysis expertise. | Risk of unnecessary maintenance and unexpected failures between intervals. |

| Data Inputs | Vibration analysis, temperature monitoring, oil analysis, ultrasonic testing. | Operating hours, calendar dates, manufacturer guidelines. |

| Cost Implications | Higher initial setup cost, lower long-term maintenance expenses. | Lower upfront cost, potentially higher lifecycle maintenance costs. |

Understanding Condition-Based Maintenance in Marine Engineering

Condition-based maintenance in marine engineering relies on real-time data from sensors monitoring engine performance and environmental parameters to predict failures before they occur. This approach enhances vessel reliability and reduces downtime by targeting repairs only when specific indicators show signs of degradation. Planned maintenance, by contrast, follows fixed schedules regardless of equipment condition, potentially leading to unnecessary servicing or unexpected breakdowns.

Planned Maintenance: Definition and Principles

Planned maintenance involves scheduled inspections and servicing based on predetermined intervals to prevent equipment failure and extend asset lifespan. This maintenance strategy is guided by principles of consistency, thoroughness, and documentation, ensuring all tasks are systematically executed regardless of equipment condition. Data-driven scheduling and adherence to manufacturer recommendations are essential components of effective planned maintenance programs.

Key Differences Between Condition-Based and Planned Maintenance

Condition-based maintenance relies on real-time data from sensors to predict equipment failures, enabling maintenance only when needed, whereas planned maintenance schedules routine checks and repairs at fixed intervals regardless of equipment condition. Condition-based approaches optimize resource usage and reduce downtime by addressing issues precisely when they arise, while planned maintenance can lead to unnecessary servicing or unexpected breakdowns due to fixed scheduling. The key difference lies in condition-based maintenance's dependence on continuous monitoring for proactive interventions contrasted with planned maintenance's reliance on time-based preventive routines.

Benefits of Condition-Based Maintenance for Ships

Condition-based maintenance for ships enhances operational efficiency by utilizing real-time data from sensors to predict equipment failures, reducing unexpected downtime and costly repairs. This approach optimizes maintenance schedules based on actual equipment condition, extending asset life and minimizing resource wastage compared to traditional planned maintenance. Improved safety and compliance with maritime regulations are achieved through timely interventions, ensuring vessel reliability and performance on demanding sea routes.

Advantages of Planned Maintenance in Marine Operations

Planned maintenance in marine operations ensures systematic scheduling of inspections and repairs, minimizing unexpected equipment failures and enhancing vessel reliability. It facilitates resource allocation and labor management, reducing downtime and operational costs by preventing emergency repairs. Consistent maintenance intervals improve safety compliance and extend the lifespan of critical marine machinery, promoting overall fleet efficiency.

Technology and Tools for Condition Monitoring at Sea

Condition-based maintenance at sea relies heavily on advanced sensor technologies such as vibration analysis, thermal imaging, and ultrasonic detection to continuously monitor the health of ship machinery. Real-time data acquisition systems and IoT-enabled platforms facilitate predictive analytics, enabling early detection of faults before failures occur. In contrast, planned maintenance depends on scheduled inspections and manual checks, often lacking the immediate diagnostic capabilities provided by condition monitoring tools.

Cost Comparison: Condition-Based vs Planned Maintenance

Condition-based maintenance (CBM) typically reduces overall maintenance costs by addressing issues only when sensor data or system condition indicators signal potential failure, minimizing unnecessary labor and parts expenses. Planned maintenance incurs higher fixed recurring costs due to scheduled inspections and routine part replacements regardless of actual equipment condition, often leading to over-maintenance and resource inefficiencies. Studies show CBM can lower maintenance costs by 20-30% compared to traditional planned maintenance through optimized resource allocation and extended asset life.

Challenges and Limitations of Each Maintenance Approach

Condition-based maintenance faces challenges in accurately predicting equipment failure due to sensor inaccuracies and data interpretation complexities, which can lead to unexpected downtime. Planned maintenance is limited by its reliance on fixed schedules, often resulting in unnecessary maintenance actions or missed early signs of failure, increasing operational costs. Both approaches require significant investments in technology and skilled personnel, making integration and scalability difficult in diverse industrial environments.

Implementing a Hybrid Maintenance Strategy on Vessels

Implementing a hybrid maintenance strategy on vessels combines condition-based maintenance (CBM) and planned maintenance to optimize operational efficiency and reduce downtime. CBM leverages real-time sensor data and predictive analytics to address equipment issues before failure, while planned maintenance follows a scheduled approach to systematically service critical components. Integrating these methods enhances vessel reliability by targeting interventions based on actual equipment health and time-based criteria, ultimately improving safety and lowering maintenance costs.

Future Trends in Marine Maintenance Practices

Condition-based maintenance leverages IoT sensors and real-time data analytics to monitor marine engine performance, reducing unplanned downtime and optimizing resource allocation. Planned maintenance remains essential for regulatory compliance but is increasingly complemented by predictive algorithms that forecast component wear and failure. Future marine maintenance trends emphasize integration of AI-driven diagnostics and digital twins to enhance vessel reliability and operational efficiency.

Predictive diagnostics

Condition-based maintenance utilizes predictive diagnostics by continuously monitoring equipment health to anticipate failures, whereas planned maintenance relies on scheduled intervals without real-time data analysis.

Real-time monitoring

Condition-based maintenance leverages real-time monitoring data to predict equipment failures and schedule interventions only when necessary, whereas planned maintenance relies on fixed schedules regardless of actual equipment condition.

Failure mode analysis

Condition-based maintenance utilizes real-time failure mode analysis to detect equipment degradation early, while planned maintenance relies on scheduled intervals without specific failure mode insights.

Vibration analysis

Condition-based maintenance using vibration analysis detects equipment faults in real-time to reduce unplanned downtime, while planned maintenance relies on scheduled inspections regardless of actual machine condition.

Oil debris analysis

Oil debris analysis in condition-based maintenance detects equipment wear in real-time, reducing unexpected failures compared to the fixed schedule approach of planned maintenance.

Lifecycle cost optimization

Condition-based maintenance reduces lifecycle costs by minimizing unplanned downtime and extending asset lifespan, whereas planned maintenance often incurs higher costs due to fixed schedules regardless of equipment condition.

Scheduled overhauls

Scheduled overhauls in planned maintenance occur at fixed intervals regardless of equipment condition, whereas condition-based maintenance schedules overhauls based on real-time asset performance data to optimize downtime and extend machinery lifespan.

Thermographic inspection

Thermographic inspection enhances condition-based maintenance by providing real-time thermal data to detect equipment anomalies early, unlike planned maintenance which relies on fixed schedules regardless of actual asset condition.

Maintenance intervals

Condition-based maintenance adjusts maintenance intervals based on real-time equipment condition data, whereas planned maintenance follows fixed, predetermined schedules regardless of actual equipment status.

Reliability-centered maintenance

Reliability-centered maintenance prioritizes condition-based maintenance by continuously monitoring asset performance to optimize maintenance schedules, unlike planned maintenance which follows fixed intervals regardless of actual equipment condition.

Condition-based maintenance vs Planned maintenance Infographic

njnir.com

njnir.com