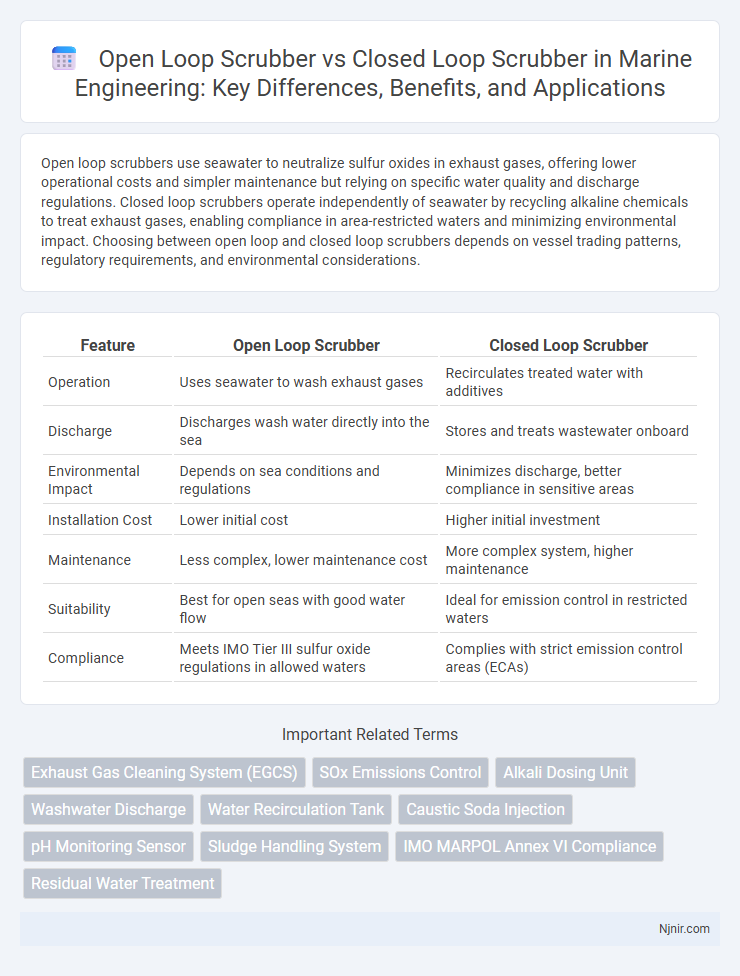

Open loop scrubbers use seawater to neutralize sulfur oxides in exhaust gases, offering lower operational costs and simpler maintenance but relying on specific water quality and discharge regulations. Closed loop scrubbers operate independently of seawater by recycling alkaline chemicals to treat exhaust gases, enabling compliance in area-restricted waters and minimizing environmental impact. Choosing between open loop and closed loop scrubbers depends on vessel trading patterns, regulatory requirements, and environmental considerations.

Table of Comparison

| Feature | Open Loop Scrubber | Closed Loop Scrubber |

|---|---|---|

| Operation | Uses seawater to wash exhaust gases | Recirculates treated water with additives |

| Discharge | Discharges wash water directly into the sea | Stores and treats wastewater onboard |

| Environmental Impact | Depends on sea conditions and regulations | Minimizes discharge, better compliance in sensitive areas |

| Installation Cost | Lower initial cost | Higher initial investment |

| Maintenance | Less complex, lower maintenance cost | More complex system, higher maintenance |

| Suitability | Best for open seas with good water flow | Ideal for emission control in restricted waters |

| Compliance | Meets IMO Tier III sulfur oxide regulations in allowed waters | Complies with strict emission control areas (ECAs) |

Introduction to Marine Scrubber Systems

Marine scrubber systems are essential for reducing sulfur oxide (SOx) emissions from ship exhaust gases. Open loop scrubbers use seawater to absorb and neutralize pollutants before discharging the wash water back into the ocean, while closed loop scrubbers recirculate alkaline water within the system, producing a concentrated waste that is stored onboard for later disposal. These technologies enable compliance with International Maritime Organization (IMO) sulfur emission limits under MARPOL Annex VI regulations.

Overview of Open Loop Scrubbers

Open loop scrubbers utilize seawater to remove sulfur oxides from ship exhaust gases, discharging the washed water back into the sea after treatment. These systems rely on the natural alkalinity of seawater to neutralize acidic compounds, making them cost-effective and simple to operate. Open loop scrubbers are most suitable in regions with strict environmental regulations allowing sea discharge and where seawater characteristics support efficient scrubbing performance.

Overview of Closed Loop Scrubbers

Closed loop scrubbers recycle wash water by continuously treating and reusing it within the system, minimizing discharge into the environment. These systems use a closed circuit with chemical additives such as caustic soda to neutralize acidic components from exhaust gases, enhancing environmental compliance particularly in emission control applications for maritime vessels. The advanced water treatment process in closed loop scrubbers significantly reduces the impact on marine ecosystems compared to open loop scrubbers by preventing contaminated water from being released directly into the sea.

Key Differences Between Open Loop and Closed Loop Scrubbers

Open loop scrubbers discharge seawater after utilizing it to neutralize sulfur oxides, relying on natural alkalinity for scrubbing, while closed loop scrubbers recirculate alkaline freshwater treated with chemicals, preventing direct seawater discharge. Open loop systems have lower operational costs and simpler maintenance but depend heavily on water quality and environment regulations, whereas closed loop systems offer greater environmental control and compliance, especially in sensitive or freshwater areas. The choice impacts fuel compatibility, regulatory adherence, and operational flexibility in marine emission control solutions.

Operational Principles of Open Loop Scrubbers

Open loop scrubbers operate by using seawater to absorb sulfur oxides (SOx) from ship exhaust gases, then discharging the treated water back into the sea after meeting regulatory standards. The system relies on the pH and alkalinity of seawater to neutralize emissions without recirculating the wash water. This operational principle contrasts with closed loop scrubbers, which continuously recycle wash water with additives for neutralization before discharge.

Operational Principles of Closed Loop Scrubbers

Closed loop scrubbers operate by recirculating a limited volume of alkaline scrubbing water mixed with chemicals, which neutralizes sulfur oxides (SOx) from ship exhaust gases. The system continuously treats and cleans the wash water within an onboard treatment unit, preventing any discharge into the ocean and minimizing environmental impact. This design contrasts with open loop scrubbers that discharge water directly overboard, relying on natural seawater for scrubbing and dilution.

Environmental Impact: Open vs Closed Loop Systems

Open loop scrubbers discharge wash water directly into the sea after treatment, potentially releasing harmful pollutants and altering local marine ecosystems. Closed loop scrubbers recycle the wash water, significantly reducing the release of contaminants and enabling better control over effluents, thereby minimizing environmental impact. Regulatory bodies often prefer closed loop systems in sensitive areas due to their superior ability to protect marine environments from acidification and heavy metals.

Regulatory Compliance and Global Restrictions

Open loop scrubbers discharge wash water directly into the sea, making them subject to stricter regulations and bans in specific regions like the Baltic Sea, North Sea, and parts of China due to environmental concerns. Closed loop scrubbers recirculate the wash water, reducing harmful discharge and often meeting stricter global regulatory standards for sulfur oxide emissions. Compliance with International Maritime Organization (IMO) sulfur limits and regional restrictions increasingly favors closed loop systems for vessels operating in Emission Control Areas (ECAs).

Cost Considerations: Installation and Operation

Open loop scrubbers typically have lower initial installation costs due to simpler design and reliance on seawater to neutralize exhaust gases, reducing the need for additional chemicals. Closed loop scrubbers involve higher upfront investments driven by complex systems and onboard chemical dosing but benefit from operational savings in areas with strict environmental regulations where discharge restrictions limit open loop systems. Operational costs of closed loop scrubbers can be higher due to chemical consumption and waste disposal, while open loop systems incur lower running costs but may face limitations in certain regions, affecting overall cost-effectiveness.

Choosing the Right Scrubber System for Marine Vessels

Selecting the appropriate scrubber system for marine vessels depends on factors like fuel type, emission regulations, and operational areas. Open loop scrubbers use seawater to neutralize sulfur oxides and are cost-effective but may face restrictions in sensitive environmental zones. Closed loop scrubbers recirculate freshwater treated with chemicals, offering compliance in strict emissions areas but requiring higher investment and maintenance.

Exhaust Gas Cleaning System (EGCS)

Open loop scrubbers discharge treated exhaust gas wash water directly into the sea, reducing sulfur emissions but relying on seawater for scrubbing, while closed loop scrubbers recycle wash water with chemical treatment, enabling effective sulfur removal and minimizing marine pollution in Exhaust Gas Cleaning Systems (EGCS).

SOx Emissions Control

Closed loop scrubbers effectively minimize SOx emissions by continuously recycling wash water, whereas open loop scrubbers discharge untreated wash water containing SOx residues into the sea.

Alkali Dosing Unit

Open loop scrubbers rely on seawater for neutralization with minimal alkali dosing, while closed loop scrubbers use an Alkali Dosing Unit to inject chemicals like sodium hydroxide for continuous pH control and effluent recycling.

Washwater Discharge

Open loop scrubbers discharge washwater containing high levels of alkalinity and trace metals directly into the sea, while closed loop scrubbers treat and recirculate washwater to minimize environmental impact by reducing contamination and discharge volume.

Water Recirculation Tank

Closed loop scrubbers utilize a water recirculation tank to continuously treat and reuse wash water, significantly reducing freshwater consumption and minimizing environmental discharge compared to open loop scrubbers that discharge untreated water directly.

Caustic Soda Injection

Open loop scrubbers discharge washwater directly into the sea, requiring minimal caustic soda injection, while closed loop scrubbers recirculate washwater and rely heavily on caustic soda injection to control pH and neutralize acidic compounds.

pH Monitoring Sensor

Closed loop scrubbers rely on advanced pH monitoring sensors to continuously regulate alkalinity and maintain optimal water quality, while open loop scrubbers typically do not require pH sensors due to their direct seawater discharge system.

Sludge Handling System

Closed loop scrubbers minimize sludge production by recycling washwater, whereas open loop scrubbers generate larger volumes of sludge requiring more complex handling and disposal systems.

IMO MARPOL Annex VI Compliance

Open loop scrubbers discharge treated seawater to comply with IMO MARPOL Annex VI sulfur emission limits, while closed loop scrubbers recycle wash water internally, preventing discharge and ensuring compliance in emission control areas.

Residual Water Treatment

Closed loop scrubbers treat residual water by continuously recycling and cleaning it through onboard filtration and neutralization systems, while open loop scrubbers discharge treated wash water directly into the sea after meeting regulatory limits without water recirculation.

open loop scrubber vs closed loop scrubber Infographic

njnir.com

njnir.com