Shaft line propulsion systems transmit engine power through a long shaft connected to a propeller, offering proven reliability and straightforward maintenance in marine engineering. Podded propulsion integrates electric motors directly into pods beneath the hull, enhancing maneuverability, reducing noise, and improving fuel efficiency. Choosing between shaft line and podded propulsion depends on vessel size, operational profile, and efficiency requirements.

Table of Comparison

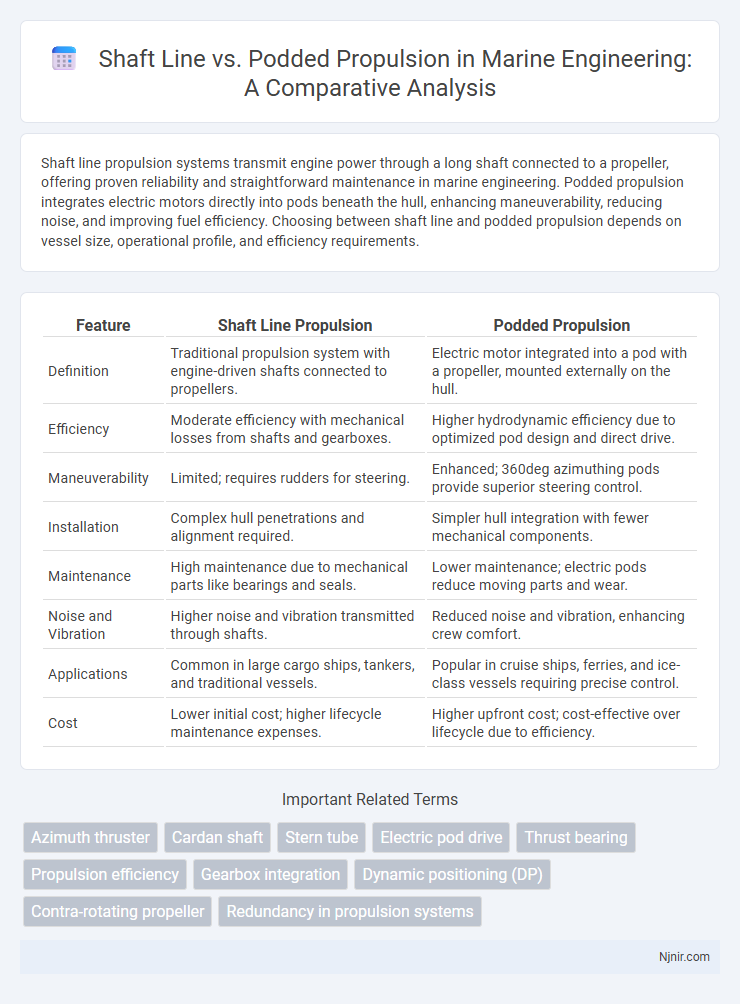

| Feature | Shaft Line Propulsion | Podded Propulsion |

|---|---|---|

| Definition | Traditional propulsion system with engine-driven shafts connected to propellers. | Electric motor integrated into a pod with a propeller, mounted externally on the hull. |

| Efficiency | Moderate efficiency with mechanical losses from shafts and gearboxes. | Higher hydrodynamic efficiency due to optimized pod design and direct drive. |

| Maneuverability | Limited; requires rudders for steering. | Enhanced; 360deg azimuthing pods provide superior steering control. |

| Installation | Complex hull penetrations and alignment required. | Simpler hull integration with fewer mechanical components. |

| Maintenance | High maintenance due to mechanical parts like bearings and seals. | Lower maintenance; electric pods reduce moving parts and wear. |

| Noise and Vibration | Higher noise and vibration transmitted through shafts. | Reduced noise and vibration, enhancing crew comfort. |

| Applications | Common in large cargo ships, tankers, and traditional vessels. | Popular in cruise ships, ferries, and ice-class vessels requiring precise control. |

| Cost | Lower initial cost; higher lifecycle maintenance expenses. | Higher upfront cost; cost-effective over lifecycle due to efficiency. |

Introduction to Marine Propulsion Systems

Shaft line propulsion utilizes a traditional setup where the engine power is transmitted through a shaft connected to a propeller, offering proven reliability and efficiency in various marine vessels. Podded propulsion systems integrate electric motors within streamlined pods outside the hull, enhancing maneuverability and reducing hydrodynamic drag for improved fuel efficiency. Choosing between shaft line and podded systems depends on vessel type, operational requirements, and energy efficiency goals in modern marine propulsion design.

Overview of Shaft Line Propulsion

Shaft line propulsion systems transfer engine power to the propeller through a long shaft, typically running from the engine room to the stern, offering proven reliability and simplicity in design. These systems feature fixed propellers and rudders, enabling efficient cruising speeds and easy maintenance in conventional vessels such as cargo ships and ferries. Despite larger hull openings and increased drag compared to podded propulsion, shaft line systems remain favored for heavy-duty maritime applications due to their robustness and cost-effectiveness.

Introduction to Podded Propulsion Technology

Podded propulsion technology integrates electric motors housed within streamlined pods attached externally to the ship's hull, enhancing maneuverability and fuel efficiency. Unlike traditional shaft line systems that transmit engine power through a long shaft to fixed propellers, podded propulsors offer 360-degree thrust vectoring, significantly improving vessel handling and reducing noise and vibration. This innovation supports greener maritime operations by optimizing energy consumption and enabling compact ship designs.

Key Components of Shaft Line and Podded Systems

Shaft line propulsion systems consist of critical components including the engine, gearbox, propeller shaft, bearings, and propeller, which work together to transmit mechanical power efficiently from the engine to the propeller. Podded propulsion systems integrate the electric motor, propeller, and steering mechanism into a single pod mounted externally, offering enhanced maneuverability and reduced vibration. Key elements such as the azimuth thruster and electrical drive system in podded setups enable precise directional control and improved hydrodynamic efficiency compared to traditional shaft lines.

Efficiency Comparison: Shaft Line vs Podded Propulsion

Shaft line propulsion systems typically offer higher mechanical efficiency by directly connecting the engine to the propeller, minimizing energy losses through fewer components. Podded propulsion, featuring integrated electric motors within steerable pods, enhances maneuverability and reduces hydrodynamic drag, which can improve overall vessel efficiency, especially at variable speeds. Efficiency outcomes depend on vessel type and operational profile, with shaft line systems favored for steady cruising and podded systems excelling in dynamic, maneuver-intensive environments.

Maneuverability and Vessel Handling Performance

Shaft line propulsion offers proven reliability and straightforward maintenance but may limit maneuverability due to fixed propeller orientation and longer response times in changing thrust direction. Podded propulsion systems enhance vessel handling performance with 360-degree rotational capability, enabling superior thrust vectoring for precise steering and improved low-speed maneuvering. This advanced control reduces the need for additional thrusters, significantly improving dynamic positioning and docking efficiency in complex maritime environments.

Installation and Maintenance Considerations

Shaft line propulsion systems require complex alignment and extensive hull modifications during installation, which can lead to longer dry-docking times and higher initial costs compared to podded propulsion. Podded units, integrated directly into the hull, offer simplified installation with fewer mechanical components, reducing labor and potential alignment issues. Maintenance of shaft lines involves regular inspection of bearings, seals, and couplings, while podded propulsion allows for more accessible unit replacement and automated diagnostics, minimizing downtime.

Impact on Fuel Consumption and Emissions

Shaft line propulsion systems typically exhibit higher fuel consumption due to mechanical losses from long transmission components, while podded propulsion offers improved energy efficiency through direct drive and optimized hydrodynamics, significantly reducing fuel usage. Reduced fuel consumption in podded systems directly correlates with lower emissions of CO2, NOx, and SOx, enhancing environmental compliance and sustainability. Advances in podded propulsion technology promote substantial fuel savings and emission reductions, making it a preferred choice for eco-friendly maritime vessels.

Suitability for Different Vessel Types

Shaft line propulsion is highly suitable for large vessels such as tankers and bulk carriers due to its robust design and efficient power transmission over long distances. Podded propulsion excels in smaller to medium-sized vessels like ferries and cruise ships by offering enhanced maneuverability and reduced hydrodynamic drag. Each system's suitability depends on vessel size, operational profile, and maintenance considerations, with pods favored for agility and shaft lines for heavy-duty applications.

Future Trends in Marine Propulsion Systems

Shaft line propulsion systems remain prevalent due to their proven reliability and efficiency in large vessels, while podded propulsion is gaining traction for its enhanced maneuverability and reduced fuel consumption, driven by advancements in electric and hybrid technologies. Future trends emphasize integrating podded systems with autonomous navigation and energy-saving innovations, promoting greener maritime operations aligned with stringent environmental regulations such as IMO 2020 and upcoming decarbonization targets. The shift towards modular, scalable propulsion units and the adoption of alternative fuels like hydrogen and ammonia further accelerate the transition from traditional shaft lines to versatile podded propulsion architectures.

Azimuth thruster

Azimuth thrusters offer superior maneuverability and precise directional control compared to traditional shaft line propulsion systems by enabling 360-degree rotation for enhanced vessel agility.

Cardan shaft

Cardan shaft in shaft line propulsion transmits torque through universal joints allowing angular misalignment, contrasting with podded propulsion systems that integrate electric motors directly into the pods for improved maneuverability and efficiency.

Stern tube

Shaft line propulsion relies on a stern tube to house and support the rotating propeller shaft, whereas podded propulsion eliminates the need for a stern tube by integrating the electric motor directly into the pod outside the hull.

Electric pod drive

Electric pod drives offer enhanced maneuverability, higher energy efficiency, and reduced maintenance compared to traditional shaft line propulsion systems by integrating electric motors directly within the pod units.

Thrust bearing

Shaft line propulsion requires heavy-duty thrust bearings to absorb axial forces from the propeller, whereas podded propulsion integrates thrust bearings within the pod, reducing shaft line complexity and improving efficiency.

Propulsion efficiency

Podded propulsion systems demonstrate higher propulsion efficiency than traditional shaft line systems by reducing hydrodynamic drag and improving maneuverability through direct thrust alignment.

Gearbox integration

Shaft line propulsion relies on complex gearbox integration to transfer engine power to the propeller shaft, whereas podded propulsion systems eliminate traditional gearboxes by incorporating electric motors directly into the pods for improved efficiency and reduced maintenance.

Dynamic positioning (DP)

Podded propulsion systems enhance Dynamic Positioning (DP) accuracy through 360-degree thrust vectoring and reduced mechanical complexity compared to traditional shaft line arrangements.

Contra-rotating propeller

Contra-rotating propeller systems integrated in podded propulsion offer enhanced thrust efficiency and maneuverability compared to traditional shaft line setups by reducing torque reactions and optimizing hydrodynamic performance.

Redundancy in propulsion systems

Podded propulsion systems offer superior redundancy compared to traditional shaft lines by enabling independent operation of multiple pods, reducing the risk of total propulsion failure.

Shaft line vs Podded propulsion Infographic

njnir.com

njnir.com