Hybrid propulsion systems in marine engineering offer a versatile balance between fuel efficiency and extended operational range by combining conventional engines with electric motors. Fully electric propulsion provides zero emissions and reduced noise pollution but is often limited by current battery technology, affecting vessel range and charging times. Choosing between hybrid and fully electric propulsion depends on vessel size, operational requirements, and environmental regulations.

Table of Comparison

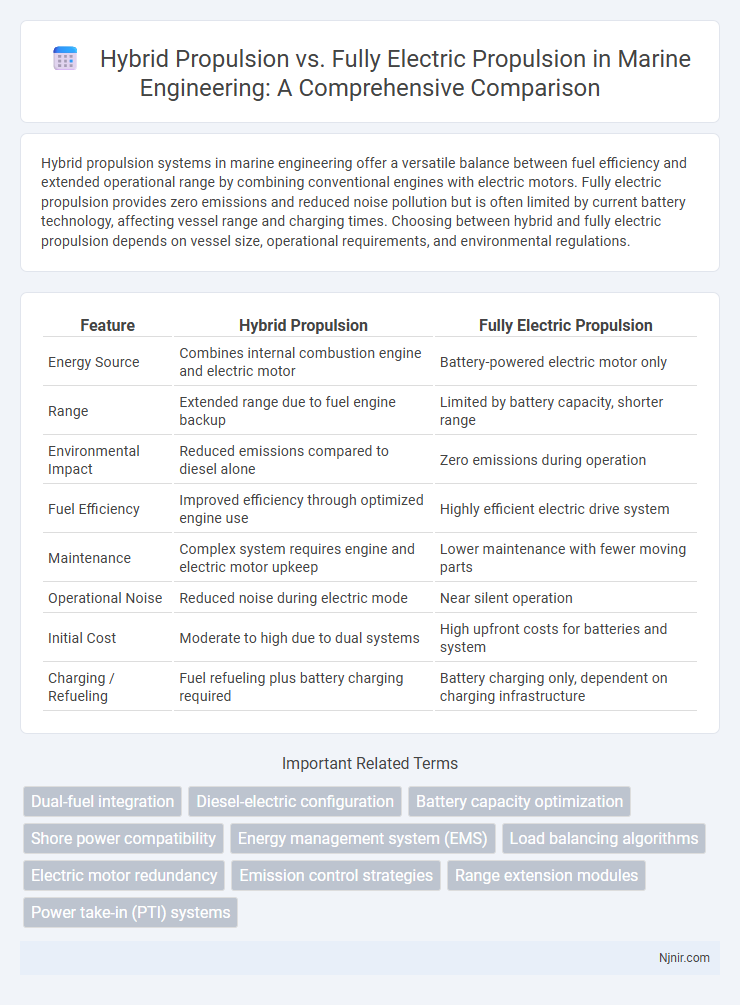

| Feature | Hybrid Propulsion | Fully Electric Propulsion |

|---|---|---|

| Energy Source | Combines internal combustion engine and electric motor | Battery-powered electric motor only |

| Range | Extended range due to fuel engine backup | Limited by battery capacity, shorter range |

| Environmental Impact | Reduced emissions compared to diesel alone | Zero emissions during operation |

| Fuel Efficiency | Improved efficiency through optimized engine use | Highly efficient electric drive system |

| Maintenance | Complex system requires engine and electric motor upkeep | Lower maintenance with fewer moving parts |

| Operational Noise | Reduced noise during electric mode | Near silent operation |

| Initial Cost | Moderate to high due to dual systems | High upfront costs for batteries and system |

| Charging / Refueling | Fuel refueling plus battery charging required | Battery charging only, dependent on charging infrastructure |

Overview of Marine Propulsion Technologies

Hybrid propulsion systems in marine vessels combine internal combustion engines with electric motors, offering enhanced fuel efficiency and reduced emissions compared to traditional engines. Fully electric propulsion relies solely on battery-powered electric motors, providing zero-emission operation and quieter performance while facing limitations in range and charging infrastructure. Advances in energy storage, motor technology, and power management are driving the adoption of both hybrid and fully electric propulsion in the marine industry.

Fundamentals of Hybrid Propulsion Systems

Hybrid propulsion systems combine an internal combustion engine with an electric motor to optimize fuel efficiency and reduce emissions, leveraging regenerative braking and battery storage for energy management. These systems operate by intelligently switching between or simultaneously using both power sources, which enhances performance and extends driving range compared to fully electric propulsion. The integration of power electronics, energy control units, and battery management systems is fundamental to the seamless functionality and efficiency of hybrid propulsion architectures.

Principles of Fully Electric Propulsion

Fully electric propulsion operates by converting electrical energy stored in batteries or fuel cells directly into mechanical power using electric motors, offering high efficiency and instant torque. Unlike hybrid systems that combine internal combustion engines with electric motors, fully electric propulsion eliminates fossil fuel use, reducing emissions and operational noise. Advanced battery technology and energy management systems optimize performance and range, making fully electric propulsion a sustainable choice for eco-friendly transportation and marine applications.

Comparative Efficiency: Hybrid vs Fully Electric

Hybrid propulsion systems offer a balance by combining internal combustion engines with electric motors, resulting in extended range and faster refueling compared to fully electric systems. Fully electric propulsion provides higher energy efficiency and lower emissions due to zero fuel combustion but is limited by current battery energy density and charging infrastructure. In terms of overall operational efficiency, fully electric vehicles excel in urban driving with regenerative braking, while hybrids outperform in long-distance or variable load conditions.

Environmental Impact and Emissions

Hybrid propulsion systems combine internal combustion engines with electric motors, reducing fuel consumption and lowering greenhouse gas emissions compared to traditional engines. Fully electric propulsion eliminates tailpipe emissions entirely, significantly reducing air pollutants and carbon footprint during operation. Lifecycle environmental impact varies depending on battery production and energy sources, with fully electric vehicles offering the greatest potential for emission reductions when powered by renewable energy.

Operational Flexibility and Performance

Hybrid propulsion systems offer greater operational flexibility by combining internal combustion engines with electric motors, enabling longer range and faster refueling compared to fully electric systems. Fully electric propulsion provides superior efficiency and lower emissions but is limited by battery capacity and longer charging times, impacting continuous operation in extended missions. Performance-wise, hybrids deliver high power output and adaptability across varying load conditions, while fully electric systems excel in quiet operation and reduced maintenance requirements.

Fuel Consumption and Cost Analysis

Hybrid propulsion systems typically achieve lower fuel consumption than conventional engines by combining an internal combustion engine with an electric motor, benefiting from regenerative braking and optimized power management. Fully electric propulsion eliminates fuel consumption entirely, offering significant operational cost savings, though initial investment and battery replacement costs remain high. Analyzing total cost of ownership, hybrids often present a lower upfront cost but higher fuel expenses, whereas fully electric vehicles incur higher initial costs offset by energy savings and reduced maintenance over time.

Challenges in Implementation and Maintenance

Hybrid propulsion systems face complex integration challenges due to the need for managing both internal combustion engines and electric components, which increases maintenance complexity and costs. Fully electric propulsion simplifies mechanical systems but demands advanced battery management and thermal regulation, posing challenges in ensuring consistent performance and longevity. Both systems require specialized skills for diagnosis, repair, and upkeep, with hybrid systems often encountering higher downtime because of their dual-technology nature.

Case Studies: Real-world Applications

Hybrid propulsion systems demonstrate efficacy in commercial aviation, evidenced by Airbus's E-Fan X project, combining electric motors with traditional jet engines to reduce fuel consumption and emissions during regional flights. Fully electric propulsion excels in urban air mobility, with companies like Joby Aviation deploying all-electric vertical takeoff and landing (eVTOL) aircraft for zero-emission short-range transport. Real-world applications highlight hybrid propulsion's potential for longer distances, while fully electric propulsion is optimal for short-haul, low-emission urban operations.

Future Trends in Marine Propulsion

Hybrid propulsion systems in marine vessels combine internal combustion engines with electric motors, offering enhanced fuel efficiency and reduced emissions, making them a practical transitional technology toward sustainability. Fully electric propulsion, powered solely by rechargeable batteries or fuel cells, represents the forefront of zero-emission marine innovation, especially for short to medium-range vessels where battery energy density meets operational demands. Emerging trends highlight increasing energy storage advancements, integration of renewable energy sources, and regulatory pressures driving the maritime sector towards comprehensive electrification to meet global decarbonization goals.

Dual-fuel integration

Dual-fuel integration in hybrid propulsion systems enhances fuel efficiency and reduces emissions by combining electric power with conventional fuels, offering greater operational flexibility than fully electric propulsion.

Diesel-electric configuration

Hybrid diesel-electric propulsion combines diesel engines and electric motors to optimize fuel efficiency and extend range compared to fully electric systems, which rely solely on battery power and offer zero emissions but limited endurance.

Battery capacity optimization

Hybrid propulsion systems optimize battery capacity by combining internal combustion engines with electric motors to extend range and reduce battery size, whereas fully electric propulsion relies solely on larger battery capacities to achieve comparable range and performance.

Shore power compatibility

Hybrid propulsion systems offer enhanced shore power compatibility by seamlessly integrating electric drive modes for efficient energy use while fully electric propulsion relies solely on shore power for battery charging, limiting operational flexibility.

Energy management system (EMS)

Hybrid propulsion systems rely on advanced Energy Management Systems (EMS) to optimize fuel efficiency by dynamically balancing internal combustion engines with electric motors, whereas fully electric propulsion depends on EMS to maximize battery use and regeneration for sustainable energy consumption.

Load balancing algorithms

Load balancing algorithms for hybrid propulsion systems optimize energy distribution between combustion engines and electric motors to enhance efficiency, outperforming fully electric propulsion by managing variable power demands and extending operational range.

Electric motor redundancy

Hybrid propulsion systems offer electric motor redundancy by integrating multiple power sources, enhancing reliability compared to fully electric propulsion, which relies solely on a single electric motor system.

Emission control strategies

Hybrid propulsion systems achieve lower emissions by combining internal combustion engines with electric motors to optimize fuel efficiency and reduce pollutants, while fully electric propulsion eliminates tailpipe emissions entirely but relies on clean energy sources to maximize environmental benefits.

Range extension modules

Hybrid propulsion systems utilize range extension modules that combine internal combustion engines with electric batteries to significantly increase vehicle range compared to fully electric propulsion, which relies solely on limited-capacity batteries.

Power take-in (PTI) systems

Hybrid propulsion systems with Power Take-In (PTI) capabilities enable efficient energy recovery and supplementary power input, enhancing fuel economy and reducing emissions compared to fully electric propulsion systems that rely solely on battery power.

hybrid propulsion vs fully electric propulsion Infographic

njnir.com

njnir.com