Air lubrication systems reduce friction between the ship's hull and water by creating a layer of microbubbles, significantly improving fuel efficiency and lowering emissions. Hull coating systems rely on specialized paints and materials to minimize biofouling and surface roughness, enhancing hydrodynamic performance and reducing maintenance costs. While air lubrication provides dynamic drag reduction during operation, hull coatings offer long-term protection and complement lubrication technology for optimal marine vessel performance.

Table of Comparison

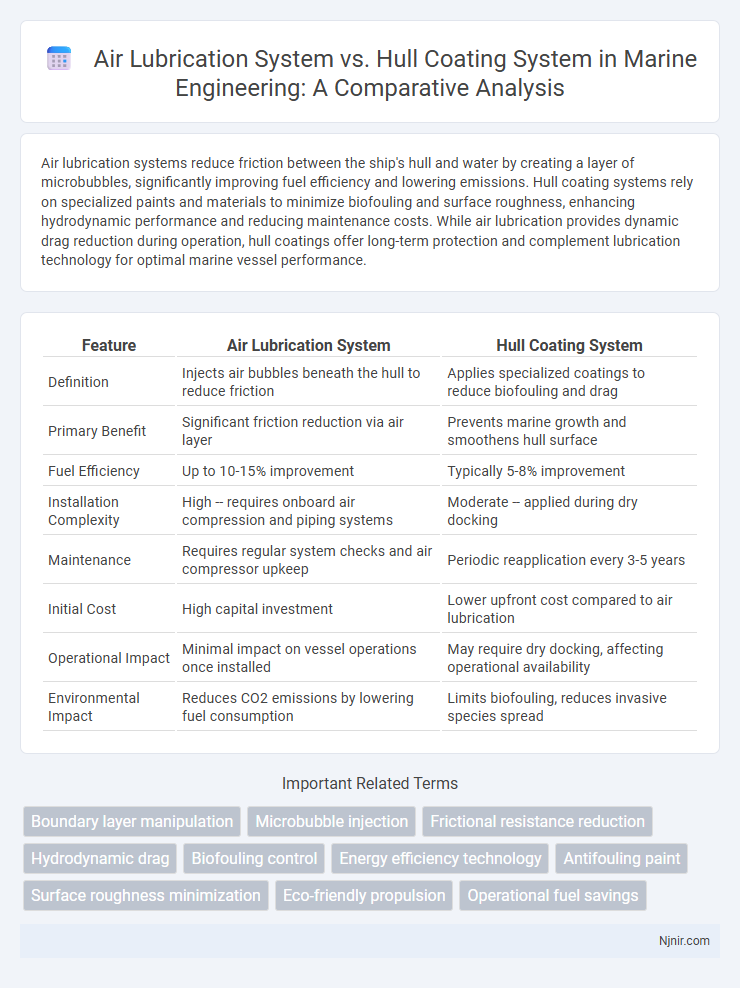

| Feature | Air Lubrication System | Hull Coating System |

|---|---|---|

| Definition | Injects air bubbles beneath the hull to reduce friction | Applies specialized coatings to reduce biofouling and drag |

| Primary Benefit | Significant friction reduction via air layer | Prevents marine growth and smoothens hull surface |

| Fuel Efficiency | Up to 10-15% improvement | Typically 5-8% improvement |

| Installation Complexity | High -- requires onboard air compression and piping systems | Moderate -- applied during dry docking |

| Maintenance | Requires regular system checks and air compressor upkeep | Periodic reapplication every 3-5 years |

| Initial Cost | High capital investment | Lower upfront cost compared to air lubrication |

| Operational Impact | Minimal impact on vessel operations once installed | May require dry docking, affecting operational availability |

| Environmental Impact | Reduces CO2 emissions by lowering fuel consumption | Limits biofouling, reduces invasive species spread |

Introduction to Hull Resistance Reduction Technologies

Air lubrication systems reduce hull resistance by creating a thin layer of air bubbles along the ship's bottom, decreasing friction between the hull and water. Hull coating systems enhance smoothness and prevent biofouling, minimizing drag caused by marine organisms attached to the hull surface. Both technologies play crucial roles in improving vessel fuel efficiency and lowering greenhouse gas emissions in maritime transportation.

Overview of Air Lubrication Systems

Air lubrication systems reduce hull friction by injecting a layer of air bubbles along the ship's bottom, improving fuel efficiency and decreasing emissions. Compared to traditional hull coating systems, which rely on specialized paints to minimize biofouling and drag, air lubrication offers a dynamic and energy-saving method without frequent reapplication. This technology is increasingly adopted on large vessels to enhance operational performance and environmental compliance.

Overview of Hull Coating Systems

Hull coating systems provide a protective layer on ship hulls to reduce frictional resistance and prevent biofouling, enhancing fuel efficiency and extending maintenance intervals. These coatings typically include antifouling paints, silicone-based foul-release coatings, and advanced epoxy resins designed to minimize drag and inhibit marine organism growth. Proper application and regular inspection of hull coatings are essential for optimal performance and compliance with environmental regulations.

Working Principles: Air Lubrication vs Hull Coating

The air lubrication system reduces frictional resistance by generating a layer of microbubbles beneath the ship's hull, creating a cushion of air that minimizes water contact and drag. In contrast, the hull coating system employs specialized antifouling paints and surface treatments that prevent marine organism attachment, thereby maintaining a smooth hull surface and reducing hydrodynamic resistance. Both methods enhance fuel efficiency, but air lubrication targets water flow dynamics while hull coatings focus on biofouling control.

Comparative Energy Efficiency Benefits

Air lubrication systems reduce hull friction by generating a thin layer of microbubbles along the ship's bottom, significantly lowering resistance and fuel consumption compared to traditional hull coating systems. While hull coatings provide a passive reduction in biofouling and surface roughness, their energy efficiency benefits diminish over time due to wear and the need for frequent reapplication. Studies indicate air lubrication can cut fuel usage by up to 10%, surpassing the typical 5% savings from high-performance hull coatings, making it a more effective solution for enhancing vessel propulsion efficiency.

Impact on Fuel Consumption and Emissions

Air lubrication systems reduce friction between the hull and water by generating a layer of microbubbles, leading to fuel savings of up to 10% and a significant decrease in greenhouse gas emissions. Hull coating systems improve hydrodynamic efficiency by minimizing surface roughness and biofouling, resulting in fuel consumption reductions typically around 5-8%. Combining both technologies offers enhanced fuel efficiency and emissions reduction by addressing different aspects of hull resistance.

Installation and Maintenance Requirements

Air lubrication systems require complex installation involving air compressors, piping, and hull modifications, resulting in higher initial costs and downtime compared to hull coating systems. Maintenance of air lubrication systems entails regular inspection and servicing of mechanical components to ensure consistent air flow and system efficiency. Hull coating systems involve simpler application processes with periodic re-coating to maintain anti-fouling properties, offering lower maintenance demands but less performance enhancement than air lubrication.

Cost Implications and Return on Investment

Air lubrication systems typically involve higher upfront installation costs compared to hull coating systems due to advanced technology and equipment requirements. Hull coatings, while less expensive initially, may require frequent reapplication and more maintenance, impacting long-term expenses. The return on investment for air lubrication systems can be more favorable over time through significant fuel savings and reduced emissions, whereas hull coatings offer immediate but smaller operational cost reductions.

Operational Challenges and Solutions

Air lubrication systems face operational challenges such as maintaining consistent air layer distribution and preventing clogging of air diffusers, which can reduce system efficiency and increase maintenance requirements. Hull coating systems encounter difficulties related to coating degradation from biofouling and mechanical wear, necessitating regular inspection and reapplication to maintain optimal performance. Solutions for air lubrication include advanced diffuser design and automated monitoring systems, while hull coating challenges are mitigated through the use of enhanced antifouling materials and robotic cleaning technologies.

Future Prospects in Marine Hull Optimization

Air lubrication systems and hull coating systems both aim to reduce friction and enhance fuel efficiency in marine vessels, but air lubrication offers greater potential for future advancements due to its dynamic adaptability and integration with smart ship technologies. Emerging innovations in air lubrication, such as microbubble generation and real-time flow control, promise significant reductions in drag and emissions compared to passive hull coatings. The synergy between air lubrication systems and hull coatings is expected to drive next-generation marine hull optimization by maximizing energy savings and extending maintenance intervals.

Boundary layer manipulation

Air lubrication systems reduce drag by generating a continuous air layer on the hull surface, effectively manipulating the boundary layer, whereas hull coating systems primarily alter surface roughness to minimize friction within the same boundary layer.

Microbubble injection

Microbubble injection in air lubrication systems significantly reduces hull friction compared to traditional hull coating systems by creating a persistent air layer that minimizes water resistance.

Frictional resistance reduction

Air lubrication systems reduce frictional resistance on ship hulls by creating a continuous layer of microbubbles, whereas hull coating systems primarily minimize resistance through surface smoothness and hydrophobic properties.

Hydrodynamic drag

Air lubrication systems reduce hydrodynamic drag by creating a continuous layer of air bubbles along the hull, while hull coating systems minimize drag by providing a smooth, low-friction surface.

Biofouling control

Air lubrication systems reduce biofouling by minimizing direct hull contact with water, while hull coating systems prevent biofouling through specialized antifouling paints that inhibit organism growth on the ship's surface.

Energy efficiency technology

Air lubrication systems reduce friction by creating a layer of microbubbles on the hull surface, significantly enhancing energy efficiency compared to traditional hull coating systems that primarily minimize surface roughness and biofouling.

Antifouling paint

The air lubrication system reduces hull resistance by creating a layer of air bubbles, whereas hull coating systems like antifouling paint prevent marine organism growth by releasing biocides to maintain vessel efficiency and reduce fuel consumption.

Surface roughness minimization

Air lubrication systems reduce surface roughness effects by creating a bubble layer that minimizes hull-water friction, whereas hull coating systems directly smooth and protect the hull surface to decrease roughness and drag.

Eco-friendly propulsion

Air lubrication systems reduce ship drag by injecting air bubbles beneath the hull, offering a more eco-friendly propulsion compared to traditional hull coating systems that rely on chemical antifouling agents.

Operational fuel savings

Air lubrication systems reduce operational fuel consumption by up to 10% through decreased hull friction, outperforming traditional hull coating systems that typically achieve fuel savings of around 3-5%.

air lubrication system vs hull coating system Infographic

njnir.com

njnir.com