Remote monitoring in marine engineering enables real-time data collection and analysis from a distance, improving maintenance efficiency and reducing downtime. Onboard monitoring systems provide immediate, localized diagnostics by directly interfacing with the vessel's equipment, ensuring prompt response to operational issues. Combining both approaches enhances overall ship safety, performance optimization, and proactive fault detection.

Table of Comparison

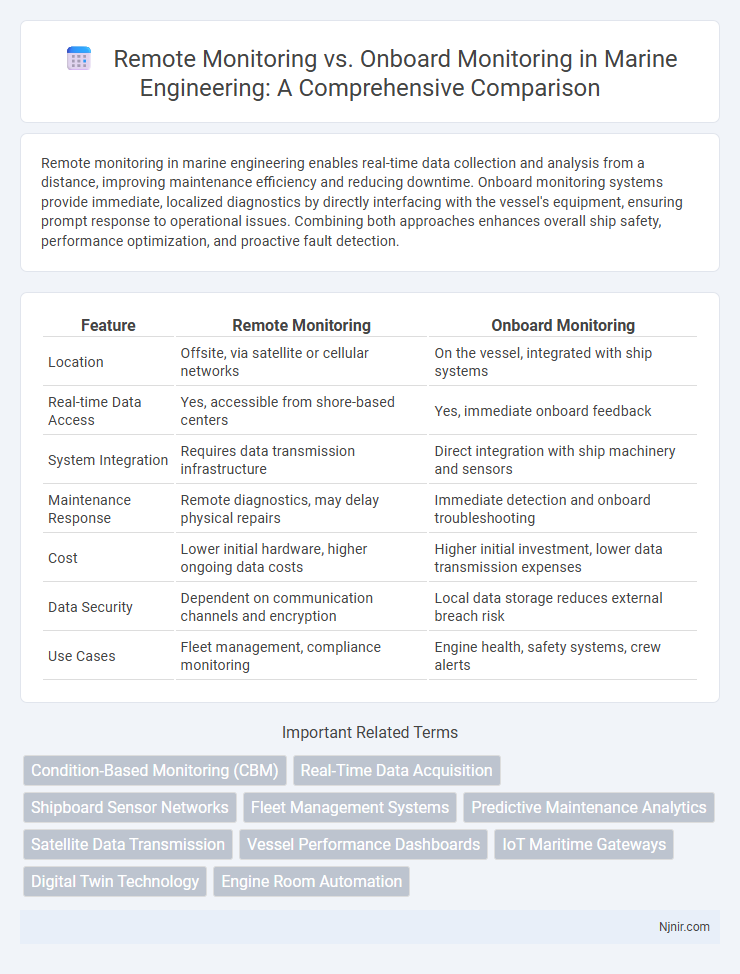

| Feature | Remote Monitoring | Onboard Monitoring |

|---|---|---|

| Location | Offsite, via satellite or cellular networks | On the vessel, integrated with ship systems |

| Real-time Data Access | Yes, accessible from shore-based centers | Yes, immediate onboard feedback |

| System Integration | Requires data transmission infrastructure | Direct integration with ship machinery and sensors |

| Maintenance Response | Remote diagnostics, may delay physical repairs | Immediate detection and onboard troubleshooting |

| Cost | Lower initial hardware, higher ongoing data costs | Higher initial investment, lower data transmission expenses |

| Data Security | Dependent on communication channels and encryption | Local data storage reduces external breach risk |

| Use Cases | Fleet management, compliance monitoring | Engine health, safety systems, crew alerts |

Introduction to Marine Monitoring Systems

Marine monitoring systems enhance vessel safety and operational efficiency by providing real-time data on engine performance, environmental conditions, and navigational status. Remote monitoring systems transmit critical information to shore-based operators, enabling proactive maintenance and rapid response without the need for physical presence onboard. Onboard monitoring systems collect and analyze data locally, offering immediate alerts and control options to the ship's crew to manage marine equipment and ensure compliance with regulatory standards.

Remote Monitoring: Overview and Capabilities

Remote monitoring enables real-time data collection and analysis from multiple locations without physical presence, enhancing operational efficiency and reducing downtime. It leverages advanced IoT sensors, cloud computing, and AI algorithms to detect anomalies, predict failures, and optimize system performance. Key capabilities include 24/7 surveillance, automated alerts, and centralized control, making it essential for industries like manufacturing, healthcare, and energy management.

Onboard Monitoring: Overview and Capabilities

Onboard monitoring systems provide real-time data collection and analysis directly on vehicles, enabling immediate response to operational changes and safety alerts. These systems integrate GPS, sensors, and diagnostic tools to monitor engine performance, driver behavior, and environmental conditions without relying on external network connectivity. Advanced onboard monitoring enhances fleet management efficiency, reduces downtime, and supports compliance with regulatory standards through continuous, in-situ data access.

Key Differences Between Remote and Onboard Monitoring

Remote monitoring leverages cloud-based platforms allowing real-time data access and analysis from multiple locations, enhancing scalability and centralized control. Onboard monitoring systems rely on local sensors and processors within the equipment, providing immediate data processing and quicker response times without dependence on internet connectivity. Key differences include data accessibility, latency, and infrastructure requirements, with remote monitoring enabling broader oversight and onboard monitoring offering faster, localized decision-making.

Advantages of Remote Monitoring in Marine Engineering

Remote monitoring in marine engineering offers continuous real-time data access, enabling proactive maintenance and early fault detection which significantly reduces downtime and repair costs. It allows for centralized oversight of multiple vessels regardless of location, improving operational efficiency and response times. Enhanced data analytics from remote sensors optimize fuel consumption and engine performance, contributing to safer and more environmentally friendly maritime operations.

Benefits of Onboard Monitoring for Vessel Operations

Onboard monitoring enhances vessel operations by providing real-time data on engine performance, fuel consumption, and equipment status, enabling immediate detection and resolution of issues. It improves safety and efficiency through continuous tracking of critical parameters without reliance on external communication systems. This proactive approach reduces downtime, minimizes operational costs, and optimizes maintenance schedules directly on the vessel.

Challenges and Limitations: Remote vs Onboard Monitoring

Remote monitoring faces challenges such as dependency on stable internet connectivity, potential data latency, and cybersecurity vulnerabilities that can compromise real-time data accuracy and system integrity. Onboard monitoring, while offering immediate data access and reduced latency, encounters limitations including limited hardware processing capabilities, higher power consumption, and constraints in data storage capacity. Both methods require robust data management strategies to address scalability issues and ensure effective fault detection under varying operational conditions.

Data Security and Reliability in Marine Monitoring Systems

Remote monitoring in marine systems enhances data security by transmitting encrypted real-time information to centralized servers, reducing the risk of data loss due to local hardware failures. Onboard monitoring ensures continuous data acquisition with minimal latency, providing reliable performance even in communication blackouts but requires robust local security protocols to prevent unauthorized access. Combining both methods optimizes marine monitoring systems by balancing secure cloud storage and resilient local data processing for comprehensive reliability.

Integration of Remote and Onboard Monitoring Technologies

Integrating remote monitoring with onboard monitoring technologies enhances real-time data accuracy and operational efficiency by combining centralized analysis with immediate system diagnostics. This synergy enables seamless data exchange through IoT platforms, facilitating proactive maintenance and reducing downtime in critical infrastructure sectors. Advanced analytics and cloud-based monitoring solutions further optimize asset management by providing comprehensive insights from both remote and onboard sources.

Future Trends in Marine Monitoring Solutions

Remote monitoring in marine applications leverages satellite communication and IoT sensors to provide real-time data on vessel performance, environmental conditions, and operational status from afar. Onboard monitoring integrates advanced AI and edge computing to analyze data locally, enabling immediate decision-making and predictive maintenance without dependency on continuous connectivity. Future trends point towards hybrid systems combining remote and onboard monitoring, enhanced by 5G connectivity, machine learning algorithms, and blockchain for secure data transparency, driving smarter, safer, and more efficient maritime operations.

Condition-Based Monitoring (CBM)

Condition-Based Monitoring (CBM) leveraging remote monitoring enables real-time data analysis and predictive maintenance from any location, whereas onboard monitoring relies on local sensors and processing power for immediate fault detection and analysis on the equipment itself.

Real-Time Data Acquisition

Remote monitoring enables continuous real-time data acquisition from multiple locations without on-site presence, while onboard monitoring captures and processes real-time data directly within the equipment for immediate analysis and response.

Shipboard Sensor Networks

Shipboard sensor networks enable real-time remote monitoring by transmitting critical vessel data to shore-based systems, contrasting with onboard monitoring which relies solely on local data processing within the ship.

Fleet Management Systems

Remote monitoring in fleet management systems enables real-time tracking and diagnostics via cloud-based platforms, while onboard monitoring relies on vehicle-installed sensors and devices for immediate data collection and localized decision-making.

Predictive Maintenance Analytics

Remote monitoring leverages real-time data analytics from dispersed equipment to enable predictive maintenance, while onboard monitoring processes sensor data locally to predict failures, both optimizing maintenance schedules and reducing downtime.

Satellite Data Transmission

Remote monitoring leverages satellite data transmission to enable real-time, long-distance asset tracking and diagnostics, while onboard monitoring processes and stores data locally with limited transmission capabilities.

Vessel Performance Dashboards

Vessel Performance Dashboards utilizing remote monitoring provide real-time data analysis and predictive insights, enhancing operational efficiency compared to onboard monitoring systems limited by onboard processing and data storage constraints.

IoT Maritime Gateways

Remote monitoring with IoT maritime gateways enables real-time vessel data transmission to shore-based systems, while onboard monitoring processes data locally for immediate decision-making and reduces latency in maritime operations.

Digital Twin Technology

Digital Twin Technology enhances remote monitoring by providing real-time, virtual replicas of assets that enable predictive maintenance, whereas onboard monitoring offers localized data collection limited to the physical asset's immediate conditions.

Engine Room Automation

Remote monitoring enables real-time data analysis and fault detection from the Engine Room Automation system offsite, while onboard monitoring provides direct, immediate control and response capabilities within the engine room environment.

Remote monitoring vs Onboard monitoring Infographic

njnir.com

njnir.com