Small modular reactors (SMRs) offer enhanced safety features and flexible deployment compared to large conventional reactors, enabling modular scalability and reduced initial capital investment. They utilize passive cooling systems and advanced materials to minimize accident risks while supporting decentralized power generation in remote or smaller grids. By contrast, large conventional reactors provide high output but involve longer construction times and higher financial risks, limiting adaptability in rapidly changing energy markets.

Table of Comparison

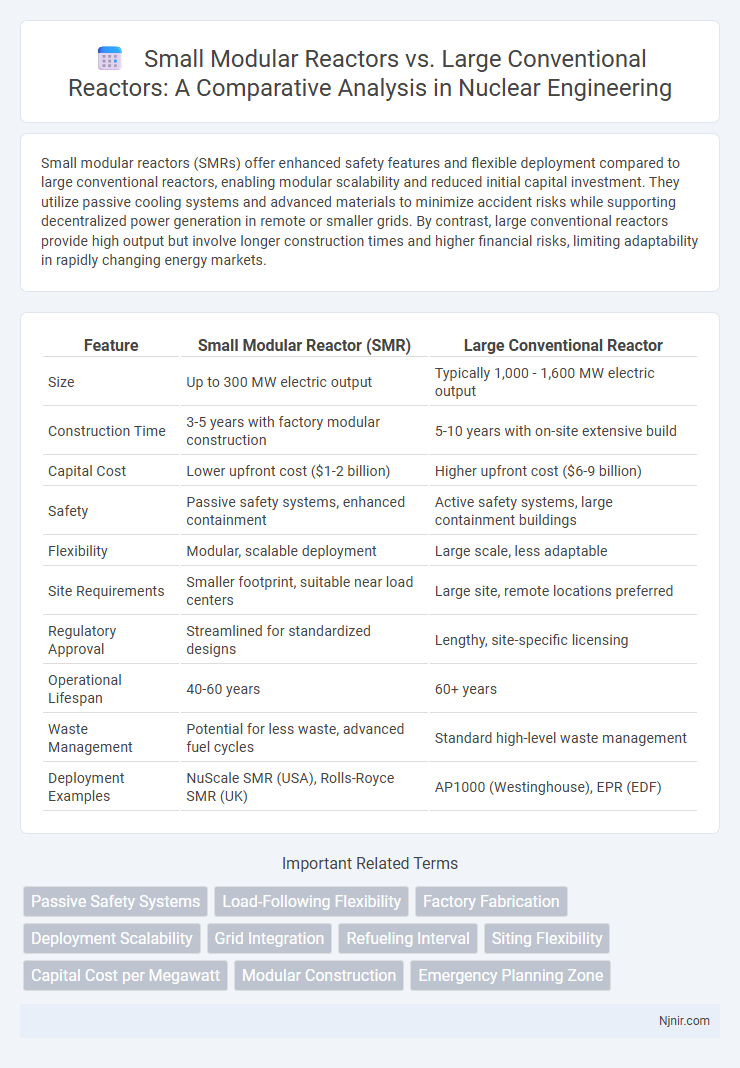

| Feature | Small Modular Reactor (SMR) | Large Conventional Reactor |

|---|---|---|

| Size | Up to 300 MW electric output | Typically 1,000 - 1,600 MW electric output |

| Construction Time | 3-5 years with factory modular construction | 5-10 years with on-site extensive build |

| Capital Cost | Lower upfront cost ($1-2 billion) | Higher upfront cost ($6-9 billion) |

| Safety | Passive safety systems, enhanced containment | Active safety systems, large containment buildings |

| Flexibility | Modular, scalable deployment | Large scale, less adaptable |

| Site Requirements | Smaller footprint, suitable near load centers | Large site, remote locations preferred |

| Regulatory Approval | Streamlined for standardized designs | Lengthy, site-specific licensing |

| Operational Lifespan | 40-60 years | 60+ years |

| Waste Management | Potential for less waste, advanced fuel cycles | Standard high-level waste management |

| Deployment Examples | NuScale SMR (USA), Rolls-Royce SMR (UK) | AP1000 (Westinghouse), EPR (EDF) |

Introduction to Small Modular Reactors and Large Conventional Reactors

Small Modular Reactors (SMRs) offer scalable nuclear power solutions with modular components typically generating up to 300 MWe, enabling flexible deployment and reduced capital investment. Large Conventional Reactors commonly exceed 1,000 MWe, delivering high baseload power but require significant upfront construction costs and extended build times. SMRs utilize advanced designs for enhanced safety and simplified operation, contrasting with the traditional large-scale pressurized water reactors dominating the global nuclear energy market.

Design Principles and Technological Differences

Small modular reactors (SMRs) prioritize modularity, scalability, and enhanced safety through passive cooling systems, compact designs, and factory-based manufacturing processes, contrasting with large conventional reactors that rely on centralized, large-scale infrastructure and active safety mechanisms. SMRs integrate advanced materials and digital instrumentation for real-time monitoring, offering flexible deployment in remote locations, whereas large reactors use established technologies optimized for maximum power output and grid stability. The technological differences highlight SMRs' lower upfront capital costs and faster construction timelines compared to the high-capacity, long-lead-time construction of traditional large nuclear plants.

Safety Features and Risk Assessment

Small modular reactors (SMRs) incorporate passive safety systems that rely on natural circulation and gravity, reducing the likelihood of operator error and enhancing resilience to power outages. Large conventional reactors often depend on active safety mechanisms requiring external power and complex control systems, increasing potential vulnerabilities during emergencies. Risk assessments indicate that SMRs' compact design and modular construction enable containment of radioactive materials more effectively, lowering the probability and impact of accidents compared to large conventional reactors.

Economic and Cost Analysis

Small modular reactors (SMRs) offer significant economic advantages through lower upfront capital costs, modular construction, and reduced financing risks compared to large conventional reactors, which require billions in initial investment and extended construction timelines. The economies of scale in large reactors often lead to cost overruns and delays, while SMRs benefit from factory fabrication and standardized designs that streamline manufacturing and shorten deployment schedules. Operational cost efficiencies in SMRs arise from enhanced safety features reducing complex safety systems and maintenance expenditures, ultimately improving the levelized cost of electricity (LCOE) and enabling more flexible, scalable power generation.

Flexibility and Scalability in Energy Deployment

Small modular reactors (SMRs) offer superior flexibility by enabling incremental power additions and easier integration with renewable energy sources, while large conventional reactors provide high output but limited operational adaptability. SMRs support scalability through factory fabrication and modular deployment, reducing construction time and capital risk compared to the extensive infrastructure required for traditional large reactors. This modular approach enhances grid responsiveness and allows tailored energy solutions for diverse demand patterns.

Licensing, Regulatory, and Siting Considerations

Small modular reactors (SMRs) benefit from streamlined licensing processes due to their reduced size, standardized design, and modular construction, which can simplify regulatory evaluation and shorten approval timelines compared to large conventional reactors. Regulatory frameworks for SMRs emphasize enhanced safety features, passive cooling systems, and reduced emergency planning zones, enabling more flexible siting options closer to population centers or industrial sites. Large conventional reactors face more complex licensing with extensive safety assessments, larger exclusion zones, and stricter siting criteria due to higher risk profiles and larger radiological impacts.

Fuel Utilization and Waste Management

Small modular reactors (SMRs) achieve higher fuel utilization through advanced designs that operate at higher burnup rates and employ more efficient fuel cycles, reducing spent fuel volume compared to large conventional reactors. SMRs often utilize passive safety features and modular fuel assemblies that simplify waste handling and enable more effective separation and recycling of nuclear materials. In contrast, large conventional reactors produce larger quantities of long-lived radioactive waste, requiring more extensive storage and disposal infrastructure.

Grid Integration and Load Following Capabilities

Small modular reactors (SMRs) offer enhanced grid integration due to their smaller size and modular design, allowing for flexible deployment in remote or off-grid locations and easier scalability to match demand. SMRs excel in load-following capabilities, adjusting output rapidly to accommodate fluctuations in electricity demand and complement variable renewable energy sources. In contrast, large conventional reactors typically provide steady baseload power with limited flexibility, posing challenges for integration with dynamic grid conditions and renewable energy systems.

Environmental Impact and Sustainability

Small modular reactors (SMRs) offer reduced environmental impact compared to large conventional reactors by producing less nuclear waste and requiring smaller land footprints. SMRs enhance sustainability through modular construction that allows scalability, rapid deployment, and integration with renewable energy systems. Their inherent safety features minimize the risk of catastrophic failures, supporting long-term ecological preservation and resource efficiency.

Future Prospects and Industry Trends

Small modular reactors (SMRs) are gaining traction due to their scalable deployment, lower upfront capital costs, and enhanced safety features compared to large conventional reactors. The nuclear industry is increasingly investing in advanced SMR designs that promise flexible integration with renewable energy sources and reduced construction timelines. Market forecasts predict significant growth for SMRs driven by supportive regulatory frameworks, decarbonization goals, and the demand for distributed power generation.

Passive Safety Systems

Small modular reactors employ advanced passive safety systems that automatically cool the reactor without external power, enhancing safety compared to large conventional reactors reliant on active safety mechanisms.

Load-Following Flexibility

Small modular reactors offer superior load-following flexibility compared to large conventional reactors, enabling more responsive and efficient adjustment to fluctuating electricity demand.

Factory Fabrication

Small modular reactors (SMRs) offer enhanced factory fabrication benefits with standardized, factory-built components enabling faster assembly, lower onsite construction costs, and improved quality control compared to large conventional reactors requiring extensive onsite construction and customization.

Deployment Scalability

Small modular reactors enable faster, cost-effective deployment with scalable capacity, whereas large conventional reactors require extensive construction timelines and substantial upfront investment, limiting scalability.

Grid Integration

Small modular reactors enable easier grid integration with flexible output and reduced infrastructure demands compared to large conventional reactors, which require extensive grid upgrades and have limited adaptability to fluctuating power needs.

Refueling Interval

Small modular reactors typically feature longer refueling intervals, often exceeding 2 years, compared to large conventional reactors that usually require refueling every 12 to 24 months.

Siting Flexibility

Small modular reactors (SMRs) offer greater siting flexibility than large conventional reactors due to their compact size, modular construction, and lower infrastructure requirements, enabling deployment in diverse locations including remote or urban areas.

Capital Cost per Megawatt

Small modular reactors typically exhibit lower capital costs per megawatt compared to large conventional reactors due to modular construction and streamlined installation processes.

Modular Construction

Small modular reactors feature factory-fabricated modular construction enabling faster, cost-effective assembly and scalability compared to the on-site, labor-intensive construction of large conventional reactors.

Emergency Planning Zone

Small modular reactors typically require significantly smaller Emergency Planning Zones compared to large conventional reactors due to their enhanced safety features and lower radioactive inventory.

small modular reactor vs large conventional reactor Infographic

njnir.com

njnir.com