Digital twin farming leverages real-time data and advanced simulations to create precise virtual replicas of agricultural environments, enabling optimized crop management and predictive maintenance. Physical model analysis relies on tangible, scaled-down versions of farming systems to study environmental interactions but lacks the dynamic adaptability and continuous data integration of digital twins. Integrating digital twin technology enhances decision-making accuracy by providing scalable, real-time insights compared to traditional physical models.

Table of Comparison

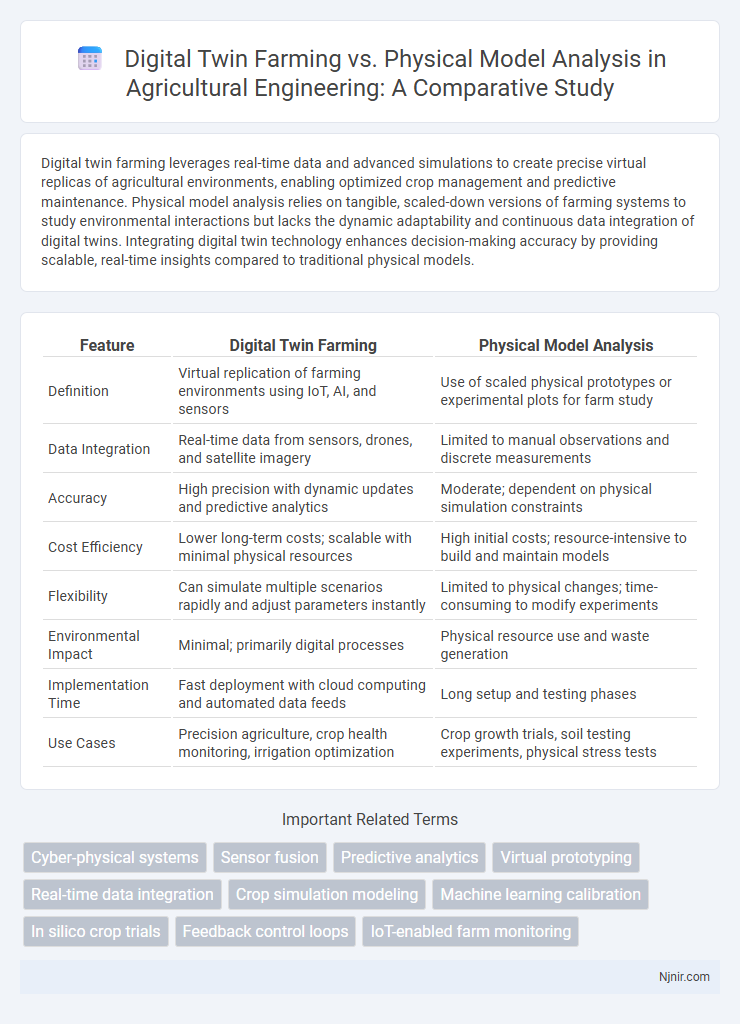

| Feature | Digital Twin Farming | Physical Model Analysis |

|---|---|---|

| Definition | Virtual replication of farming environments using IoT, AI, and sensors | Use of scaled physical prototypes or experimental plots for farm study |

| Data Integration | Real-time data from sensors, drones, and satellite imagery | Limited to manual observations and discrete measurements |

| Accuracy | High precision with dynamic updates and predictive analytics | Moderate; dependent on physical simulation constraints |

| Cost Efficiency | Lower long-term costs; scalable with minimal physical resources | High initial costs; resource-intensive to build and maintain models |

| Flexibility | Can simulate multiple scenarios rapidly and adjust parameters instantly | Limited to physical changes; time-consuming to modify experiments |

| Environmental Impact | Minimal; primarily digital processes | Physical resource use and waste generation |

| Implementation Time | Fast deployment with cloud computing and automated data feeds | Long setup and testing phases |

| Use Cases | Precision agriculture, crop health monitoring, irrigation optimization | Crop growth trials, soil testing experiments, physical stress tests |

Overview of Digital Twin Technology in Agriculture

Digital twin technology in agriculture creates a virtual replica of physical farming systems, enabling real-time monitoring and data-driven decision-making to optimize crop yields and resource use. This digital representation integrates IoT sensors, satellite data, and AI analytics, offering precise simulations of environmental conditions and plant health. Compared to traditional physical model analysis, digital twins provide dynamic, scalable, and predictive insights that enhance precision farming and sustainability efforts.

Understanding Physical Model Analysis in Farming

Physical model analysis in farming involves creating scaled-down or simplified representations of agricultural systems to study interactions between soil, water, crops, and environmental factors. This approach allows for controlled experimentation and prediction of outcomes under various farming conditions, aiding in optimizing irrigation, fertilization, and crop management strategies. While less dynamic than digital twin farming, physical models provide tangible insights into complex processes, enhancing practical understanding of farm operations and resource efficiency.

Key Differences: Digital Twin vs. Physical Model Analysis

Digital twin farming leverages real-time data and IoT sensors to create dynamic virtual replicas of agricultural systems for continuous monitoring and predictive analysis. Physical model analysis relies on static, scaled-down or prototype versions to study farming processes, often lacking real-time adaptability. The key difference lies in digital twin's integration of live data enabling proactive decision-making, whereas physical models provide observational insights without ongoing interaction.

Advantages of Digital Twin Farming

Digital twin farming offers real-time monitoring and precise simulation of crop growth by integrating sensor data, weather conditions, and soil health, enabling predictive analytics that optimize resource usage and increase yield. Compared to physical model analysis, digital twins provide scalable, cost-effective experimentation without the risks and delays associated with physical prototypes. Their ability to quickly adapt to changing environmental variables enhances decision-making accuracy and accelerates innovation in agricultural practices.

Limitations of Physical Model Analysis

Physical model analysis in farming faces significant limitations such as scale constraints and high costs, making it challenging to accurately represent complex agricultural environments. Physical models often lack real-time data integration and adaptability, reducing their effectiveness in dynamic farming conditions. Compared to digital twin farming, which utilizes extensive sensor data and simulation, physical models provide less predictive capability and flexibility.

Data Integration and Real-Time Monitoring

Digital twin farming leverages advanced data integration techniques by combining IoT sensors, satellite imagery, and machine learning algorithms to create dynamic, real-time virtual replicas of physical farms. This enables continuous real-time monitoring and predictive analytics, allowing farmers to optimize resource use and crop yields with greater precision compared to traditional physical model analysis, which relies on static, often delayed data collection. The seamless integration of heterogeneous data sources in digital twin systems significantly enhances decision-making accuracy and operational efficiency in modern agriculture.

Predictive Analytics and Decision Support

Digital twin farming leverages real-time data and machine learning algorithms for enhanced predictive analytics, enabling precise forecasting of crop yields, soil health, and pest outbreaks. Physical model analysis relies on controlled experimental setups and historical data to simulate farming conditions, but lacks the dynamic adaptability of digital twins. Integration of digital twins with decision support systems improves farm management by providing actionable insights and optimizing resource allocation more effectively than traditional physical models.

Cost Implications and Resource Efficiency

Digital twin farming significantly reduces operational costs by enabling precise simulation of crop growth and resource utilization, minimizing waste and lowering energy consumption compared to physical model analysis. Physical models often require extensive materials and labor for setup and experimentation, leading to higher expenditures and slower iteration cycles. The digital approach enhances resource efficiency through real-time data integration and predictive analytics, optimizing water usage, fertilizer application, and pest management with greater accuracy.

Scalability and Customization in Farm Applications

Digital twin farming offers superior scalability by simulating vast and diverse agricultural environments using real-time data integration, enabling dynamic adjustments for large-scale operations. Customization in digital twins allows precise modeling of specific crop conditions, soil types, and climate variations, significantly enhancing decision-making accuracy compared to static physical model analysis. Physical models remain limited by their fixed parameters and scale, making digital twin technology far more adaptable for modern farm management and optimization.

Future Prospects and Emerging Trends

Digital twin farming harnesses real-time data integration and advanced AI to simulate crop growth and soil conditions, offering dynamic predictive analytics that surpass the static insights of traditional physical model analysis. Future prospects include enhanced precision agriculture through IoT-enabled sensors, machine learning algorithms for yield optimization, and scalable digital replicas adaptable across diverse agroecosystems. Emerging trends focus on integrating blockchain for data transparency, leveraging 5G connectivity for real-time monitoring, and employing augmented reality interfaces to facilitate decision-making in smart farming practices.

Cyber-physical systems

Digital twin farming integrates real-time sensor data and advanced simulations within cyber-physical systems to outperform traditional physical model analysis by enabling dynamic, precise crop management and predictive decision-making.

Sensor fusion

Sensor fusion in digital twin farming integrates multisource real-time data to enhance precision and predictive accuracy beyond the static insights provided by physical model analysis.

Predictive analytics

Digital twin farming leverages real-time data and predictive analytics to simulate crop growth and optimize resource use more accurately than traditional physical model analysis.

Virtual prototyping

Digital twin farming enables dynamic virtual prototyping by integrating real-time data for precise crop simulation, surpassing traditional static physical model analysis in accuracy and efficiency.

Real-time data integration

Digital twin farming leverages real-time data integration to simulate and optimize crop growth dynamically, whereas physical model analysis relies on static data and manual adjustments without continuous feedback.

Crop simulation modeling

Digital twin farming leverages real-time data integration for dynamic crop simulation modeling, providing more precise and adaptive growth predictions compared to static, predefined parameters used in physical model analysis.

Machine learning calibration

Machine learning calibration in digital twin farming enables real-time, data-driven optimization of crop performance, surpassing the static and less adaptive insights provided by physical model analysis.

In silico crop trials

In silico crop trials using digital twin farming provide precise, scalable insights compared to physical model analysis by simulating environmental variables and genetic traits for optimized agricultural outcomes.

Feedback control loops

Digital twin farming leverages real-time data and feedback control loops for dynamic crop management, whereas physical model analysis relies on static, predefined parameters with limited adaptability to environmental changes.

IoT-enabled farm monitoring

IoT-enabled digital twin farming provides real-time, scalable data integration and predictive analytics, vastly improving accuracy and efficiency over traditional physical model analysis in farm monitoring.

Digital twin farming vs Physical model analysis Infographic

njnir.com

njnir.com