Algae biofuel offers higher yield per acre and faster growth rates compared to cellulosic ethanol, making it a more efficient source of renewable energy. Its ability to thrive in non-arable land and use wastewater reduces competition with food crops, addressing sustainability concerns associated with cellulosic ethanol. While cellulosic ethanol relies on lignocellulosic biomass that requires extensive pretreatment, algae biofuel production benefits from simpler harvesting and conversion processes, enhancing overall cost-effectiveness and scalability.

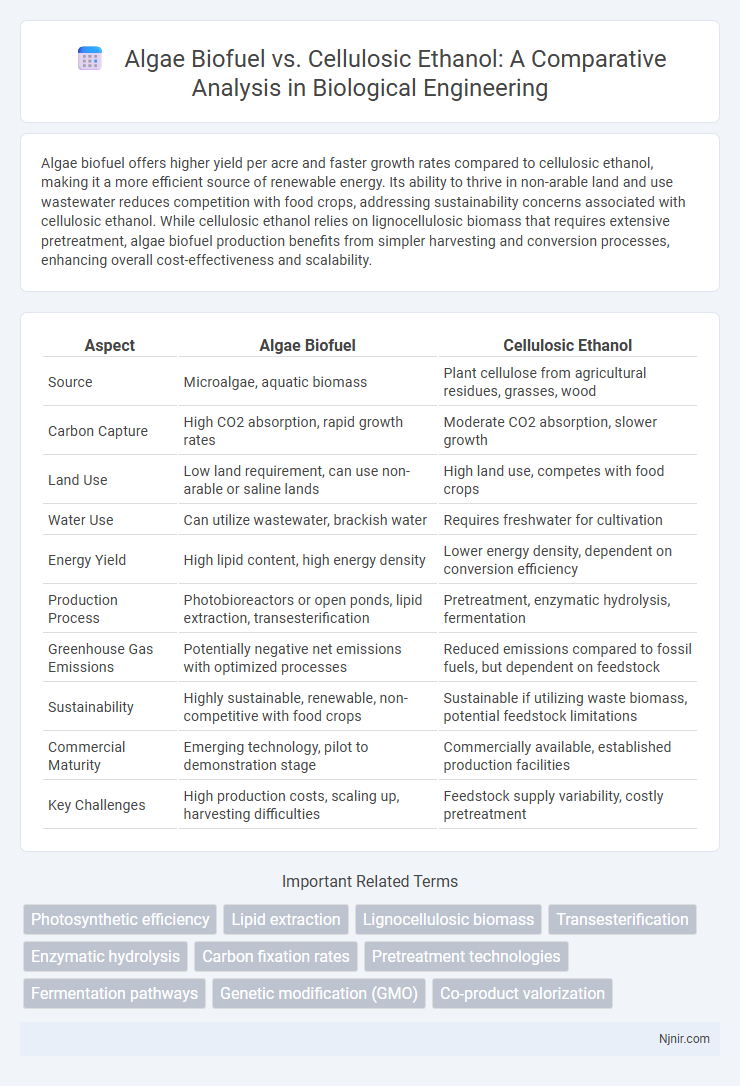

Table of Comparison

| Aspect | Algae Biofuel | Cellulosic Ethanol |

|---|---|---|

| Source | Microalgae, aquatic biomass | Plant cellulose from agricultural residues, grasses, wood |

| Carbon Capture | High CO2 absorption, rapid growth rates | Moderate CO2 absorption, slower growth |

| Land Use | Low land requirement, can use non-arable or saline lands | High land use, competes with food crops |

| Water Use | Can utilize wastewater, brackish water | Requires freshwater for cultivation |

| Energy Yield | High lipid content, high energy density | Lower energy density, dependent on conversion efficiency |

| Production Process | Photobioreactors or open ponds, lipid extraction, transesterification | Pretreatment, enzymatic hydrolysis, fermentation |

| Greenhouse Gas Emissions | Potentially negative net emissions with optimized processes | Reduced emissions compared to fossil fuels, but dependent on feedstock |

| Sustainability | Highly sustainable, renewable, non-competitive with food crops | Sustainable if utilizing waste biomass, potential feedstock limitations |

| Commercial Maturity | Emerging technology, pilot to demonstration stage | Commercially available, established production facilities |

| Key Challenges | High production costs, scaling up, harvesting difficulties | Feedstock supply variability, costly pretreatment |

Introduction to Biofuels: Algae vs. Cellulosic Ethanol

Algae biofuel and cellulosic ethanol represent two innovative biofuel sources with distinct production methods and feedstocks. Algae biofuel is derived from microscopic algae rich in lipids, offering high yield per acre and potential for carbon dioxide absorption during growth. Cellulosic ethanol is produced from non-food plant materials like agricultural residues and grasses, utilizing cellulose conversion technologies to generate sustainable liquid fuel with lower greenhouse gas emissions.

Feedstock Sources and Availability

Algae biofuel relies primarily on microalgae cultivated in aquatic environments, offering high lipid content and rapid growth rates in diverse conditions, including non-arable land and wastewater, which reduces competition with food crops. Cellulosic ethanol is produced from lignocellulosic biomass such as agricultural residues, grasses, and wood chips, abundant but seasonally variable feedstocks requiring extensive pretreatment for conversion. The consistent year-round availability and high productivity of algae feedstock make it a promising alternative to cellulosic sources, which depend on geographically and seasonally constrained biomass supplies.

Photosynthetic Efficiency and Yield Potential

Algae biofuel exhibits significantly higher photosynthetic efficiency, converting up to 8-10% of solar energy into biomass compared to roughly 1-2% in cellulosic ethanol feedstocks like switchgrass or miscanthus. This enhanced efficiency enables algae to produce much greater lipid yields per acre annually, often exceeding 5,000 gallons per acre versus the 400-800 gallons per acre typical of cellulosic ethanol crops. Consequently, algae biofuels present a superior yield potential and faster biomass accumulation, making them a promising alternative in sustainable bioenergy production.

Conversion Technologies and Processes

Algae biofuel conversion primarily involves lipid extraction followed by transesterification to produce biodiesel or hydrothermal liquefaction for bio-crude, leveraging fast-growing microalgae with high lipid content. Cellulosic ethanol is produced through enzymatic hydrolysis of cellulose and hemicellulose in biomass, followed by fermentation of the resulting sugars using specialized microbes, requiring pretreatment methods such as steam explosion or acid hydrolysis to break down plant cell walls. Both technologies face challenges in scalability and process optimization but offer sustainable alternatives to fossil fuels through distinct biochemical conversion pathways.

Land and Water Use Considerations

Algae biofuel production requires significantly less arable land compared to cellulosic ethanol, as algae can be cultivated in non-arable areas such as saltwater ponds and wastewater, minimizing competition with food crops. Water use efficiency is higher in algae biofuel systems, with some species capable of growing in brackish or saline water, whereas cellulosic ethanol relies heavily on freshwater for crop irrigation and processing. The ability of algae to utilize marginal land and alternative water sources offers a sustainable advantage in regions facing land scarcity and water stress.

Greenhouse Gas Emissions and Environmental Impact

Algae biofuel significantly reduces greenhouse gas emissions by absorbing CO2 during cultivation and producing higher energy yields per acre compared to cellulosic ethanol, which relies on lignocellulosic biomass like crop residues. The environmental impact of algae biofuel is lower due to minimal land use change and reduced water consumption, whereas cellulosic ethanol can lead to deforestation and soil degradation when biomass harvesting is not managed sustainably. Life cycle assessments show algae biofuel offers a more favorable carbon footprint and less biodiversity disruption, making it a promising renewable energy source for mitigating climate change.

Economic Viability and Production Costs

Algae biofuel offers higher yield per acre and faster growth rates compared to cellulosic ethanol, but its production costs remain significantly higher due to expensive cultivation and harvesting technologies. Cellulosic ethanol benefits from utilizing abundant agricultural residues, resulting in lower feedstock costs and more established processing methods, enhancing its economic viability. Despite algae biofuel's potential for sustainability and carbon reduction, current market prices favor cellulosic ethanol as a more cost-effective biofuel source.

Scalability and Commercial Deployment

Algae biofuel offers high scalability potential due to rapid biomass growth rates and the ability to cultivate on non-arable land, reducing competition with food crops, whereas cellulosic ethanol depends on the availability of large volumes of agricultural residues and dedicated energy crops. Commercial deployment of algae biofuel remains limited by high production costs and technological challenges in harvesting and processing, while cellulosic ethanol has achieved more significant commercial milestones with facilities operating globally, though still facing economic barriers for widespread adoption. Investment in research and infrastructure is critical to overcome scalability constraints and drive cost reductions for both biofuels to become competitive alternatives in the renewable energy market.

Technological Challenges and Innovations

Algae biofuel faces technological challenges such as high production costs, efficient lipid extraction, and scaling up photobioreactors to optimize growth conditions, while innovations in genetic engineering and bioreactor design enhance yield and reduce expenses. Cellulosic ethanol encounters difficulties in breaking down complex lignocellulosic biomass into fermentable sugars, prompting advances in enzyme technology, pretreatment methods, and microbial fermentation to improve conversion efficiency. Both biofuels rely on ongoing research to overcome obstacles in feedstock variability, process integration, and sustainability to achieve commercial viability.

Future Prospects and Research Directions

Algae biofuel offers promising future prospects due to its high biomass yield, rapid growth rates, and ability to utilize non-arable land and wastewater, making it a sustainable alternative to fossil fuels. Research is increasingly focused on genetic engineering to enhance lipid production, optimizing cultivation systems, and improving cost-effective harvesting methods. Cellulosic ethanol research centers on advancing enzyme technologies for more efficient cellulose breakdown, developing robust microbial strains for fermentation, and integrating biorefinery approaches to improve overall production economics.

Photosynthetic efficiency

Algae biofuel exhibits higher photosynthetic efficiency, converting up to 5-8% of solar energy into biomass, compared to cellulosic ethanol's efficiency of approximately 1-2%, making algae a more sustainable source for bioenergy production.

Lipid extraction

Lipid extraction from algae biofuel yields higher energy density oils compared to the cellulose breakdown in cellulosic ethanol, making algae lipids more efficient for biodiesel production.

Lignocellulosic biomass

Lignocellulosic biomass from agricultural residues offers a cost-effective and sustainable feedstock for cellulosic ethanol production, while algae biofuel provides higher oil yields and faster growth rates but requires advanced cultivation systems.

Transesterification

Algae biofuel undergoes transesterification to efficiently produce high-yield biodiesel with superior lipid content compared to cellulosic ethanol, which primarily relies on fermentation of cellulose-derived sugars.

Enzymatic hydrolysis

Enzymatic hydrolysis in cellulosic ethanol production breaks down complex cellulose into fermentable sugars more efficiently than algae biofuel processes, which primarily rely on lipid extraction rather than carbohydrate conversion.

Carbon fixation rates

Algae biofuel exhibits significantly higher carbon fixation rates than cellulosic ethanol, enabling more efficient CO2 capture and renewable energy production.

Pretreatment technologies

Algae biofuel production leverages minimal pretreatment due to high lipid content, whereas cellulosic ethanol requires intensive pretreatment methods like steam explosion or acid hydrolysis to break down complex lignocellulosic biomass into fermentable sugars.

Fermentation pathways

Algae biofuel utilizes lipid extraction followed by transesterification, whereas cellulosic ethanol relies on enzymatic hydrolysis and microbial fermentation of cellulose-derived sugars through pathways such as ethanolic fermentation.

Genetic modification (GMO)

Genetic modification enhances algae biofuel production by increasing lipid yields, whereas cellulosic ethanol benefits from GMO crops engineered for higher cellulose content and improved enzymatic digestibility.

Co-product valorization

Algae biofuel production offers higher co-product valorization through valuable outputs like animal feed, pharmaceuticals, and bioplastics, while cellulosic ethanol primarily generates lignin for energy but with fewer high-value co-products.

Algae biofuel vs Cellulosic ethanol Infographic

njnir.com

njnir.com