Biocatalysis harnesses enzymes and microorganisms to drive highly selective and efficient chemical reactions under mild conditions, reducing energy consumption and waste generation compared to traditional chemical synthesis. Chemical synthesis often relies on harsh reagents and extreme temperatures, which can lead to lower specificity and increased environmental impact. Emphasizing biocatalysis in biological engineering enhances sustainable production of pharmaceuticals, biofuels, and fine chemicals by leveraging nature's catalytic precision.

Table of Comparison

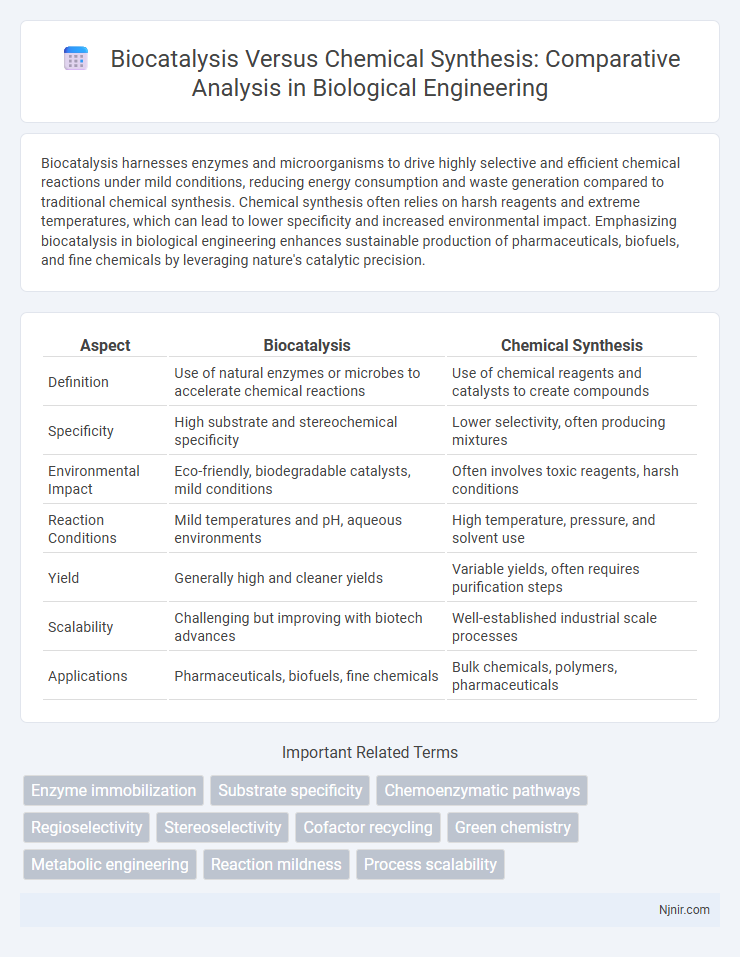

| Aspect | Biocatalysis | Chemical Synthesis |

|---|---|---|

| Definition | Use of natural enzymes or microbes to accelerate chemical reactions | Use of chemical reagents and catalysts to create compounds |

| Specificity | High substrate and stereochemical specificity | Lower selectivity, often producing mixtures |

| Environmental Impact | Eco-friendly, biodegradable catalysts, mild conditions | Often involves toxic reagents, harsh conditions |

| Reaction Conditions | Mild temperatures and pH, aqueous environments | High temperature, pressure, and solvent use |

| Yield | Generally high and cleaner yields | Variable yields, often requires purification steps |

| Scalability | Challenging but improving with biotech advances | Well-established industrial scale processes |

| Applications | Pharmaceuticals, biofuels, fine chemicals | Bulk chemicals, polymers, pharmaceuticals |

Introduction to Biocatalysis and Chemical Synthesis

Biocatalysis utilizes natural enzymes or whole cells to accelerate chemical reactions, enabling highly selective transformations under mild conditions. Chemical synthesis involves traditional methods using inorganic or organic catalysts to construct molecules through stepwise chemical reactions, often requiring harsh reagents and conditions. Biocatalysis offers advantages in sustainability, specificity, and environmental impact compared to conventional chemical synthesis approaches.

Mechanisms of Biocatalysis in Biological Engineering

Biocatalysis in biological engineering employs enzymes that facilitate highly specific catalytic mechanisms through substrate binding and transition state stabilization, resulting in efficient and selective biochemical transformations under mild conditions. Enzymatic mechanisms involve precise active site interactions, such as nucleophilic attack, acid-base catalysis, and covalent intermediate formation, which enhance reaction rates and reduce byproduct formation compared to chemical synthesis. This molecular specificity and environmentally friendly process enable biocatalysis to outperform traditional chemical synthesis in producing chiral molecules and complex biochemicals with reduced energy consumption and waste generation.

Fundamental Principles of Chemical Synthesis

Chemical synthesis involves the deliberate construction of molecules through chemical reactions that form new covalent bonds, often using catalysts, reagents, and controlled reaction conditions to achieve desired transformations with high selectivity and yield. The fundamental principles emphasize reaction mechanisms, thermodynamics, and kinetics to optimize pathways for efficient production of target compounds, prioritizing factors like atom economy, stereoselectivity, and step economy. Understanding the electronic and steric effects of substrates and reagents guides the design of synthetic routes, enabling precise control over molecular architecture compared to the enzyme-specific selectivity found in biocatalysis.

Enzyme Engineering for Biocatalytic Processes

Enzyme engineering enhances biocatalytic processes by optimizing enzyme specificity, stability, and activity, surpassing traditional chemical synthesis in selectivity and environmental sustainability. Tailored biocatalysts enable efficient transformation of complex substrates under mild conditions, reducing hazardous reagents and energy consumption characteristic of chemical synthesis. Advances in directed evolution and rational design accelerate the development of robust enzymes, expanding the application scope of biocatalysis in pharmaceutical and industrial production.

Selectivity and Specificity: Biocatalysts vs Chemical Catalysts

Biocatalysts exhibit superior selectivity and specificity due to their ability to recognize and transform substrates with high precision, resulting from their highly evolved active sites. Chemical catalysts often lack this molecular recognition, leading to broader reactivity and the formation of unwanted by-products. The enhanced selectivity of biocatalysts reduces purification steps and increases overall process efficiency in synthetic applications.

Environmental Sustainability: Green Chemistry Perspectives

Biocatalysis offers significant advantages over chemical synthesis by utilizing enzymes that operate under mild conditions, reducing energy consumption and minimizing hazardous waste generation. This enzymatic approach aligns with green chemistry principles by enhancing reaction specificity and decreasing reliance on toxic solvents and heavy metals. Consequently, biocatalysis supports environmental sustainability through lower carbon footprints and safer manufacturing processes.

Process Efficiency and Reaction Conditions

Biocatalysis offers superior process efficiency by enabling highly selective reactions under mild conditions such as ambient temperature and neutral pH, reducing energy consumption and minimizing by-product formation. Chemical synthesis often requires harsh reaction conditions, including elevated temperatures, strong acids or bases, and toxic solvents, which can lead to lower selectivity and increased waste. Enzyme-catalyzed reactions typically achieve higher turnover rates and enantioselectivity, making biocatalysis a greener and more sustainable alternative for complex molecule production.

Scalability and Industrial Applications

Biocatalysis offers enhanced regio- and stereoselectivity in chemical transformations, often operating under mild conditions that reduce energy consumption and hazardous waste, which supports scalable production in pharmaceutical and fine chemical industries. Chemical synthesis, while traditionally favored for large-scale bulk manufacturing due to established processes and broader substrate scope, can face limitations in selectivity and the need for harsh reagents, impacting sustainability and safety in industrial settings. The integration of biocatalytic methods into chemical synthesis pipelines is driving advancements in green chemistry, making large-scale industrial applications more efficient and environmentally friendly.

Challenges and Limitations in Biocatalysis and Chemical Synthesis

Biocatalysis faces challenges such as enzyme stability under industrial conditions, limited substrate scope, and high production costs for enzymes, which restrict scalability and industrial application. Chemical synthesis often encounters limitations including harsh reaction conditions, low selectivity, and generation of hazardous waste, impacting environmental sustainability and product purity. Both approaches require optimization to balance efficiency, cost-effectiveness, and environmental impact in large-scale manufacturing processes.

Future Trends in Biomanufacturing Technologies

Future trends in biomanufacturing technologies emphasize biocatalysis as a sustainable alternative to traditional chemical synthesis, leveraging enzyme engineering and synthetic biology to enhance specificity and efficiency. Advances in protein engineering enable tailored enzymes that reduce environmental impact and improve reaction conditions, driving cost-effective production processes. Integration of artificial intelligence with biocatalysis accelerates pathway optimization, offering scalable solutions for pharmaceuticals, biofuels, and specialty chemicals.

Enzyme immobilization

Enzyme immobilization enhances biocatalysis by improving enzyme stability, reuse, and selectivity compared to traditional chemical synthesis methods.

Substrate specificity

Biocatalysis offers higher substrate specificity than chemical synthesis, enabling selective reactions with fewer byproducts and greater efficiency in complex molecule production.

Chemoenzymatic pathways

Chemoenzymatic pathways integrate biocatalysis with chemical synthesis to enhance reaction specificity, sustainability, and overall efficiency in complex molecule production.

Regioselectivity

Biocatalysis offers superior regioselectivity compared to chemical synthesis by utilizing enzymes that precisely target specific reaction sites, reducing side products and enhancing yield.

Stereoselectivity

Biocatalysis offers superior stereoselectivity compared to chemical synthesis by utilizing enzymes that precisely control the formation of chiral centers in complex molecules.

Cofactor recycling

Cofactor recycling in biocatalysis enhances reaction efficiency and sustainability by regenerating essential molecules like NADH and ATP, whereas chemical synthesis often relies on stoichiometric reagents without effective cofactor regeneration.

Green chemistry

Biocatalysis enhances green chemistry by using enzymes as biodegradable catalysts that operate under mild conditions, reducing hazardous waste and energy consumption compared to traditional chemical synthesis.

Metabolic engineering

Metabolic engineering enhances biocatalysis by optimizing microbial pathways for efficient, sustainable production of complex molecules compared to traditional chemical synthesis.

Reaction mildness

Biocatalysis enables reaction mildness by operating under ambient temperatures and neutral pH, whereas chemical synthesis often requires harsh conditions such as high temperatures and strong acids or bases.

Process scalability

Biocatalysis offers superior process scalability compared to chemical synthesis by enabling more efficient, selective reactions under mild conditions, reducing energy consumption and waste generation in large-scale production.

Biocatalysis vs Chemical synthesis Infographic

njnir.com

njnir.com