Biocatalysis harnesses enzymes to accelerate chemical reactions with high specificity and under mild conditions, offering environmentally friendly and sustainable alternatives to traditional methods. Chemocatalysis relies on metal-based or synthetic catalysts that often operate under harsher conditions and may generate more waste. The precision and efficiency of biocatalysis make it increasingly valuable in pharmaceuticals and fine chemicals, while chemocatalysis remains dominant in large-scale industrial processes due to its robustness.

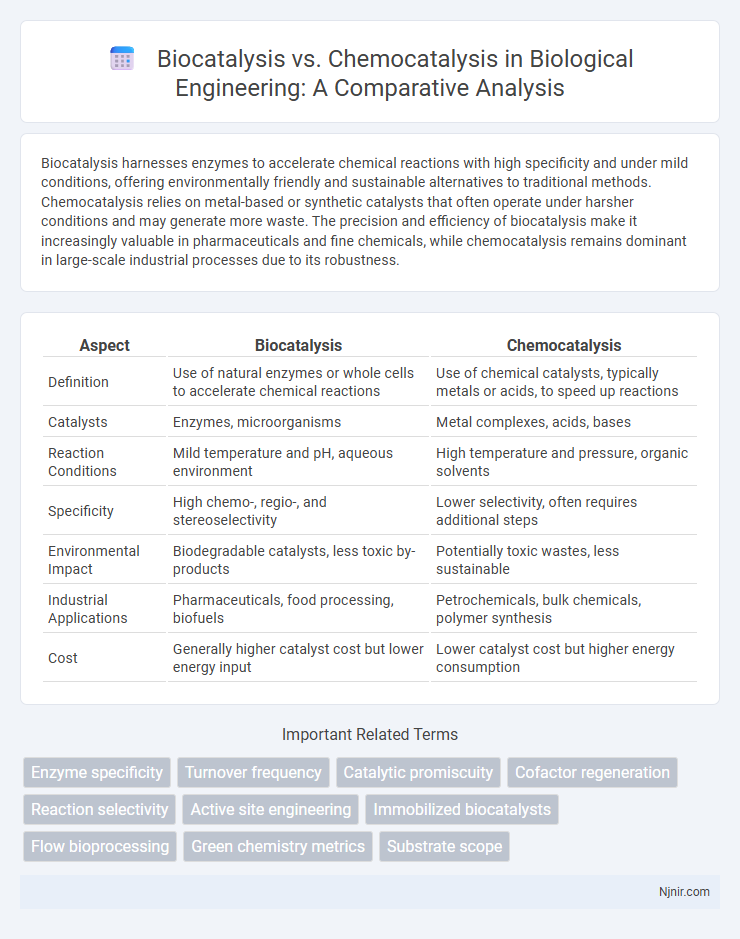

Table of Comparison

| Aspect | Biocatalysis | Chemocatalysis |

|---|---|---|

| Definition | Use of natural enzymes or whole cells to accelerate chemical reactions | Use of chemical catalysts, typically metals or acids, to speed up reactions |

| Catalysts | Enzymes, microorganisms | Metal complexes, acids, bases |

| Reaction Conditions | Mild temperature and pH, aqueous environment | High temperature and pressure, organic solvents |

| Specificity | High chemo-, regio-, and stereoselectivity | Lower selectivity, often requires additional steps |

| Environmental Impact | Biodegradable catalysts, less toxic by-products | Potentially toxic wastes, less sustainable |

| Industrial Applications | Pharmaceuticals, food processing, biofuels | Petrochemicals, bulk chemicals, polymer synthesis |

| Cost | Generally higher catalyst cost but lower energy input | Lower catalyst cost but higher energy consumption |

Introduction to Biocatalysis and Chemocatalysis

Biocatalysis utilizes enzymes or whole cells to accelerate chemical reactions with high specificity and environmental compatibility, making it ideal for producing pharmaceuticals and fine chemicals. Chemocatalysis relies on inorganic or organometallic catalysts to drive reactions, often enabling broader substrate scope and reaction conditions but with less selectivity. Both catalytic methods play crucial roles in modern synthetic chemistry, balancing sustainability and efficiency.

Fundamental Principles of Biocatalysis

Biocatalysis relies on enzymes as biological catalysts that accelerate chemical reactions with high specificity and mild reaction conditions, often operating under ambient temperature and pH. The fundamental principles include substrate specificity, enzyme-substrate binding through induced fit, and reaction acceleration via transition state stabilization. These mechanisms enable selective transformations and environmentally friendly processes, distinguishing biocatalysis from chemocatalysis, which typically uses metal or acid/base catalysts under harsher conditions.

Mechanistic Insights into Chemocatalysis

Chemocatalysis involves the acceleration of chemical reactions using metal complexes, acids, or bases, facilitating bond formation through well-defined catalytic cycles with distinct intermediates. Mechanistic insights reveal electron transfer processes, ligand coordination dynamics, and transition state stabilization as key factors influencing catalyst activity and selectivity. Understanding these parameters enables rational design of catalysts for enhanced efficiency and specificity in organic transformations.

Substrate Specificity: Biocatalysts vs Chemocatalysts

Biocatalysts exhibit high substrate specificity due to their intricate active sites, ensuring selective conversion of target molecules, which enhances reaction efficiency and reduces by-products. Chemocatalysts often display broader substrate tolerance but may require harsher conditions and generate more side reactions, impacting product purity. Understanding the substrate specificity differences between biocatalysts and chemocatalysts is crucial for optimizing industrial processes in pharmaceuticals and fine chemicals synthesis.

Reaction Efficiency and Selectivity Comparison

Biocatalysis often achieves higher reaction efficiency by operating under mild conditions with enzymes that exhibit exceptional substrate specificity, leading to fewer by-products and lower energy consumption. Chemocatalysis typically requires harsher conditions and broad-spectrum catalysts that can result in lower selectivity and increased side reactions. Enzymatic catalysts in biocatalysis provide enantioselectivity and regioselectivity superior to many chemical catalysts, making biocatalysis preferable for complex molecule synthesis.

Environmental Impact and Green Chemistry Potential

Biocatalysis offers significant environmental advantages over chemocatalysis by utilizing enzymes that operate under mild conditions, reducing energy consumption and minimizing hazardous waste. Enzymatic processes exhibit high selectivity, which lowers by-product formation and enhances overall atom economy, aligning closely with green chemistry principles. In contrast, chemocatalysis often requires harsh chemicals and elevated temperatures, leading to greater environmental burdens and diminished sustainability potential.

Industrial Applications and Case Studies

Biocatalysis leverages enzymes to drive highly selective and sustainable reactions under mild conditions, making it ideal for pharmaceuticals and fine chemical production, as demonstrated in the synthesis of atorvastatin and sitagliptin. Chemocatalysis employs metal-based catalysts to facilitate diverse transformations including hydrogenation and oxidation, widely used in petrochemical refining and bulk chemical manufacturing, exemplified by the Haber-Bosch process for ammonia synthesis. Industrial case studies highlight biocatalysis' advantage in reducing waste and energy consumption while chemocatalysis offers robustness and scalability for high-volume processes.

Engineering Challenges in Catalyst Development

Biocatalysis faces engineering challenges in enzyme stability, substrate specificity, and operational conditions such as pH and temperature, which limit its industrial scalability. Chemocatalysis requires catalyst design optimization to enhance selectivity, reduce toxicity, and improve reusability under harsh reaction environments. Both approaches demand advanced materials engineering and process integration to overcome limitations in catalyst lifespan and efficiency.

Economic Considerations in Process Scale-Up

Biocatalysis offers significant economic advantages in process scale-up due to its high selectivity, reduced energy consumption, and lower environmental compliance costs, often leading to decreased production expenses. Although chemocatalysis typically provides faster reaction rates and broader substrate scope, it incurs higher costs related to catalyst toxicity, waste treatment, and energy-intensive reaction conditions. Cost-benefit analyses favor biocatalytic processes for large-scale applications where sustainability and long-term operating expenses are critical factors.

Future Perspectives and Emerging Trends

Biocatalysis is rapidly advancing through enzyme engineering and synthetic biology, enabling more sustainable and selective chemical processes with reduced environmental impact compared to traditional chemocatalysis. Emerging trends highlight the integration of biocatalysts with chemocatalysts in cascade reactions to enhance efficiency and product diversity. Future perspectives emphasize the development of robust biocatalysts capable of operating under industrial conditions, as well as leveraging artificial intelligence for accelerated enzyme discovery and optimization.

Enzyme specificity

Enzyme specificity in biocatalysis enables highly selective substrate transformation, contrasting with the broader reactivity and lower selectivity characteristic of chemocatalysis.

Turnover frequency

Biocatalysis typically exhibits higher turnover frequency compared to chemocatalysis due to the enzyme's substrate specificity and catalytic efficiency.

Catalytic promiscuity

Catalytic promiscuity in biocatalysis enables enzymes to facilitate diverse chemical reactions beyond their primary function, offering greater substrate specificity and environmental sustainability compared to the broader but less selective reaction scope of chemocatalysis.

Cofactor regeneration

Biocatalysis enables efficient cofactor regeneration through enzyme-coupled recycling systems, whereas chemocatalysis typically requires external chemical agents or electrochemical methods to restore cofactors.

Reaction selectivity

Biocatalysis achieves higher reaction selectivity than chemocatalysis by utilizing enzymes that precisely target specific substrates and stereochemistry.

Active site engineering

Active site engineering in biocatalysis enables precise substrate specificity and catalytic efficiency by tailoring enzyme active sites, whereas chemocatalysis relies on modifying catalyst surfaces or ligands to enhance reaction rates and selectivity.

Immobilized biocatalysts

Immobilized biocatalysts enhance biocatalysis by improving enzyme stability, reusability, and selectivity compared to traditional chemocatalysis, leading to more efficient and sustainable biochemical reactions.

Flow bioprocessing

Flow bioprocessing in biocatalysis enables continuous, efficient, and selective transformations using enzymes under mild conditions, outperforming traditional chemocatalysis in sustainability and substrate specificity.

Green chemistry metrics

Biocatalysis demonstrates superior green chemistry metrics compared to chemocatalysis by offering higher atom economy, lower energy consumption, and reduced hazardous waste generation through enzymatic specificity and milder reaction conditions.

Substrate scope

Biocatalysis offers a narrower substrate scope limited to biologically compatible molecules, whereas chemocatalysis provides a broader substrate scope capable of transforming a diverse range of synthetic and non-natural substrates.

Biocatalysis vs Chemocatalysis Infographic

njnir.com

njnir.com