Biocompatible polymers are engineered to interact seamlessly with biological systems without causing adverse reactions, making them ideal for medical implants and tissue scaffolds. Biodegradable polymers, on the other hand, are designed to break down into non-toxic byproducts within the body over time, supporting temporary functions such as drug delivery or wound healing. Understanding the distinct properties of these polymers enhances the development of advanced biomaterials tailored for specific therapeutic applications.

Table of Comparison

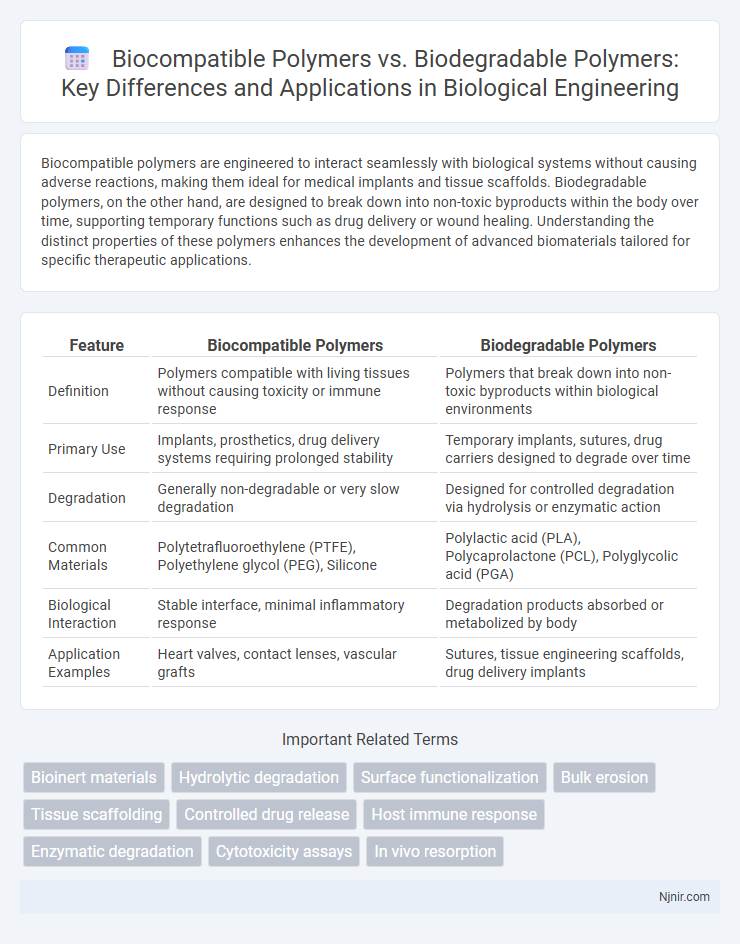

| Feature | Biocompatible Polymers | Biodegradable Polymers |

|---|---|---|

| Definition | Polymers compatible with living tissues without causing toxicity or immune response | Polymers that break down into non-toxic byproducts within biological environments |

| Primary Use | Implants, prosthetics, drug delivery systems requiring prolonged stability | Temporary implants, sutures, drug carriers designed to degrade over time |

| Degradation | Generally non-degradable or very slow degradation | Designed for controlled degradation via hydrolysis or enzymatic action |

| Common Materials | Polytetrafluoroethylene (PTFE), Polyethylene glycol (PEG), Silicone | Polylactic acid (PLA), Polycaprolactone (PCL), Polyglycolic acid (PGA) |

| Biological Interaction | Stable interface, minimal inflammatory response | Degradation products absorbed or metabolized by body |

| Application Examples | Heart valves, contact lenses, vascular grafts | Sutures, tissue engineering scaffolds, drug delivery implants |

Introduction to Biocompatible and Biodegradable Polymers

Biocompatible polymers are engineered materials designed to interact with biological systems without causing adverse reactions, making them essential in medical implants and devices. Biodegradable polymers, on the other hand, are specialized materials that break down naturally within the body or environment, reducing long-term waste and eliminating the need for surgical removal in applications like drug delivery and tissue engineering. Both types of polymers play critical roles in advancing biomedical technologies by ensuring safety and functionality while addressing environmental sustainability.

Defining Biocompatibility in Polymer Science

Biocompatible polymers are materials designed to interact with biological systems without eliciting harmful immune responses, ensuring safety and functionality in medical applications such as implants and drug delivery. Biodegradable polymers, a subset of biocompatible materials, break down into non-toxic byproducts within the body, enabling temporary therapeutic use and minimizing long-term foreign material presence. Defining biocompatibility in polymer science involves assessing cytotoxicity, immunogenicity, and tissue integration to ensure polymer compatibility with host environments.

Understanding Biodegradability in Polymer Materials

Biodegradable polymers are a subset of biocompatible polymers specifically designed to break down into natural byproducts like water, carbon dioxide, and biomass through microbial activity. Understanding biodegradability involves evaluating the polymer's chemical structure, environmental conditions, and the presence of enzymes that facilitate polymer chain cleavage. Biocompatible polymers may not degrade but must be non-toxic and compatible with biological tissues, whereas biodegradable polymers emphasize environmentally safe decomposition.

Key Differences Between Biocompatible and Biodegradable Polymers

Biocompatible polymers are engineered to interact safely with living tissues without causing immune rejection or toxicity, making them ideal for medical implants and drug delivery systems. Biodegradable polymers, on the other hand, are designed to break down naturally within the biological environment through enzymatic or hydrolytic processes, reducing long-term implant residue. Key differences lie in their purpose: biocompatible polymers prioritize non-toxicity and physiological stability, whereas biodegradable polymers emphasize environmental breakdown and absorption by the body.

Material Selection Criteria for Biomedical Applications

Material selection criteria for biomedical applications emphasize the distinction between biocompatible and biodegradable polymers based on their interaction with biological systems and degradation profiles. Biocompatible polymers, such as polyethylene glycol and polyvinyl alcohol, are chosen for their non-toxic, non-immunogenic properties, ensuring stable performance without eliciting adverse biological responses. Biodegradable polymers like polylactic acid and polyglycolic acid are selected for their controlled degradation rates, mechanical strength, and ability to be absorbed or excreted by the body, making them ideal for temporary implants and drug delivery systems.

Synthesis and Engineering of Biocompatible Polymers

Biocompatible polymers are engineered through controlled polymerization techniques like ring-opening polymerization and step-growth polymerization to ensure minimal immune response and cytotoxicity in medical applications. Their synthesis often involves functionalization with bioactive molecules to enhance cell adhesion and tissue integration, distinguishing them from biodegradable polymers primarily designed for breakdown within the body. Advanced engineering strategies include copolymerization and surface modification to tune mechanical properties and biointerface interactions, optimizing polymer performance in implants, drug delivery systems, and tissue scaffolds.

Processing and Degradation Mechanisms of Biodegradable Polymers

Biodegradable polymers undergo specific degradation mechanisms such as hydrolysis, enzymatic action, and microbial degradation, which break down polymer chains into biocompatible byproducts, facilitating controlled resorption in biological environments. Processing of biodegradable polymers requires careful optimization of parameters like temperature, pressure, and solvent use to preserve polymer integrity while enabling desired mechanical properties and degradation rates. Compared to biocompatible polymers, which focus primarily on non-toxicity and inertness, biodegradable polymers demand precise control over molecular weight, crystallinity, and copolymer composition to tailor degradation kinetics for targeted biomedical applications.

Clinical Applications: Implants, Drug Delivery, and Tissue Engineering

Biocompatible polymers such as poly(ethylene glycol) and polyvinyl alcohol are extensively used in implants and tissue engineering due to their non-toxic, non-immunogenic properties, ensuring minimal adverse reactions in vivo. Biodegradable polymers like polylactic acid and polyglycolic acid are preferred in drug delivery systems and tissue scaffolds, enabling controlled degradation and gradual drug release or tissue regeneration. Clinical applications leverage biocompatible polymers for structural support and biodegradables for temporary functions where gradual resorption is essential for healing and drug efficacy.

Regulatory and Safety Considerations

Biocompatible polymers must comply with stringent regulatory standards such as ISO 10993 to ensure non-toxicity, non-immunogenicity, and long-term stability within the human body. Biodegradable polymers face additional scrutiny regarding metabolite toxicity and controlled degradation rates to prevent adverse tissue reactions, governed by FDA and EMA guidelines. Safety assessments emphasize cytotoxicity, genotoxicity, and inflammatory response, making the regulatory pathway for biodegradable polymers more complex due to their temporal material breakdown.

Future Trends in Biocompatible and Biodegradable Polymer Research

Future trends in biocompatible and biodegradable polymer research emphasize the development of multifunctional materials combining enhanced cell compatibility with controlled degradation rates for targeted medical applications. Advances in biomimetic synthesis and nanotechnology integration enable precise tuning of polymer properties to support tissue engineering, drug delivery, and implantable devices. Emerging research focuses on sustainable polymer sources and smart polymers responsive to physiological stimuli, aiming to improve patient outcomes and reduce environmental impact.

Bioinert materials

Bioinert polymers, a subset of biocompatible polymers, provide stable interfaces in medical implants by resisting degradation and minimizing immune response, unlike biodegradable polymers that are designed to break down and be absorbed by the body.

Hydrolytic degradation

Hydrolytic degradation in biodegradable polymers involves the chemical breakdown of polymers by water, leading to material erosion and resorption, whereas biocompatible polymers are designed to minimize adverse biological responses without necessarily undergoing hydrolytic degradation.

Surface functionalization

Surface functionalization of biocompatible polymers enhances cell adhesion and immune response compatibility, whereas biodegradable polymers' surface modifications primarily control degradation rates and bioactive molecule release.

Bulk erosion

Bulk erosion in biodegradable polymers occurs as the entire polymer matrix degrades simultaneously, contrasting with biocompatible polymers that maintain structural integrity without significant degradation in biological environments.

Tissue scaffolding

Biocompatible polymers provide a non-toxic interface for tissue scaffolding, while biodegradable polymers support temporary structural frameworks that gradually degrade to facilitate natural tissue regeneration.

Controlled drug release

Biodegradable polymers enable controlled drug release by naturally breaking down within the body, whereas biocompatible polymers primarily ensure minimal immune response without necessarily degrading.

Host immune response

Biocompatible polymers minimize adverse host immune responses by integrating seamlessly with tissue, whereas biodegradable polymers actively modulate immune reactions during degradation to prevent chronic inflammation.

Enzymatic degradation

Enzymatic degradation of biodegradable polymers involves specific enzymes breaking down polymer chains into non-toxic byproducts, whereas biocompatible polymers are designed to minimize immune response without necessarily undergoing enzymatic degradation.

Cytotoxicity assays

Cytotoxicity assays reveal that biocompatible polymers exhibit minimal cellular toxicity to ensure safe implantation, while biodegradable polymers must balance controlled degradation with non-toxic byproducts to maintain cell viability.

In vivo resorption

Biodegradable polymers undergo in vivo resorption through enzymatic or hydrolytic degradation, whereas biocompatible polymers maintain structural integrity without significant in vivo resorption.

Biocompatible polymers vs Biodegradable polymers Infographic

njnir.com

njnir.com